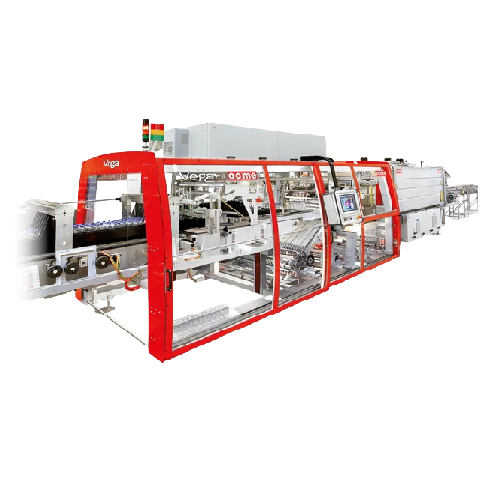

Shrink wrap packer for beverage and food industries

Optimize your production line efficiency with a versatile packer capable of handling various packaging configurations, ensuring seamless transition and high-speed operations across multiple product types.

Shrink-Wraps and Packages Various Container Types

The Vega HT from OCME is an engineered solution designed for high-speed shrink-wrapping and packaging across beverage, food, and personal care industries. This machine excels in processing a wide range of container types, from PET water bottles to canned soups, using advanced film-wrapping technology. Operating with continuous and high-speed efficiency, the Vega HT handles complex packaging tasks, integrating seamlessly into your production line with automation features like electronic selection and automatic reel splicing to minimize downtime. It boasts energy-efficient operations thanks to an energy-saving kit that preserves heat during pauses. Made from durable materials, it supports diverse packaging options such as pad and film packs or tray packs. With easy-changeover capabilities and customizable configurations, the Vega HT is built to meet specific production demands while ensuring minimal manual intervention, reducing operational costs, and maximizing productivity.

Benefits

- Enhances productivity with rapid size changeovers, minimizing line interruptions.

- Lowers energy consumption through advanced motorized curtain technology, reducing operational costs.

- Increases packaging flexibility, accommodating multiple container types and configurations.

- Streamlines operations with integrated handle applicator and automated blank feeding, decreasing manual handling.

- Ensures gentle product handling with contact-free electronic selection, protecting container labels and surfaces.

- Applications

- Food, Beverages, Lubricants, Detergents

- End products

- Canned soup, Bottled olive oil, Pet water bottles, Aerosol lubricant cans, Glass beer bottles, Canned soda, Detergent bottles

- Steps before

- Depalletizing, Sorting, Cleaning

- Steps after

- Palletizing, Labelling, Distribution

- Input ingredients

- shrink film, cans, PET bottles, glass bottles, tray, layer pad, u-board

- Output ingredients

- shrink-wrapped packages, film-only packs, pad and film packs, tray and film packs, tray only packs, bundles with easy opening

- Market info

- OCME, part of Aetna Group Italy, is renowned for manufacturing innovative, high-quality packaging and material handling solutions, including filling, palletizing, and conveying systems, with a strong reputation for reliability and technological advancement in industrial sectors.

- Performance

- High speed

- Energy Consumption

- Low

- Size Changeover

- Fast

- Automation

- Automated Splicing

- Lane Configurations

- Single / Double / Triple

- Container Types

- Cans, PET, Glass Bottles

- Pack Types

- Film-only, U-board, Nested, Tray

- Adaptability

- Total Adaptability to All Sizes

- Accessibility

- Excellent for Operators

- Components

- High Level, Safety Compliant

- Automation level

- High (PLC-controlled)

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Quick format changeover

- Energy efficiency

- Low energy consumption

- Cleaning method

- Optional CIP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- CE marking

- Yes

- ATEX certification

- Potentially applicable for explosion proof environments

- FDA compliance

- FDA approved materials

- ISO 9001

- Quality management systems

- Control panel type

- Electronic

- Size changeover

- Automatic/Motorized

- Handle applicator integration

- Integrated

- External reel loader

- Yes

- Automatic reel splicing

- Yes