Asme glass-lined reactors for chemical processing

Optimize your chemical processes with high-pressure, corrosion-resistant glass-lined reactors designed to handle extreme conditions while ensuring product integrity and safety through precise mixing and thermal control.

Processes Corrosive Chemicals and Pharmaceuticals Safely

The ASME RT, RS, RA, and RX series reactors from GMM Pfaudler are engineered to meet the rigorous demands of industries handling corrosive and sensitive materials. These glass-lined reactors offer unparalleled corrosion resistance, leveraging Pfaudler’s glass-lining expertise for enhanced safety in chemical, pharmaceutical, and food processing environments. The reactors feature multi-part or single-piece designs with options for Cryo-Lock technology, which facilitates internal assembly, especially beneficial for applications ranging from active pharmaceutical ingredient production to acid recovery and specialty chemical formulation.

With sizes spanning from 5 to 15,000 gallons, these reactors cater to diverse production scales. The inclusion of the INTERSEAL dry9000® sealing system ensures robust containment and lowers maintenance needs, while the choice of 316L stainless steel base metal in RX series extends their application to ultra-clean environments. Each reactor integrates seamlessly into existing production lines, equipped with advanced automation options and PLC capabilities to enhance efficiency and reduce operational downtime. These reactors are also compliant with ASME codes, providing assurance of safety and reliability in high-pressure scenarios.

Benefits

- Enhances safety and longevity with superior corrosion resistance in aggressive environments.

- Boosts production efficiency with user-friendly assembly and maintenance features.

- Reduces operational costs via reliable sealing systems that minimize leaks and contamination risks.

- Ensures compliance with industry standards, safeguarding process and product integrity.

- Adapts to varied operational needs with customizable design options and scalable sizes.

- Applications

- Sanitary environments, Pressure vessels, Acid recovery systems, Cryogenic applications, Energy sector applications, Food processing, Glass-lined equipment, Corrosion-resistant solutions, Chemical processes, Pharmaceutical formulations

- End products

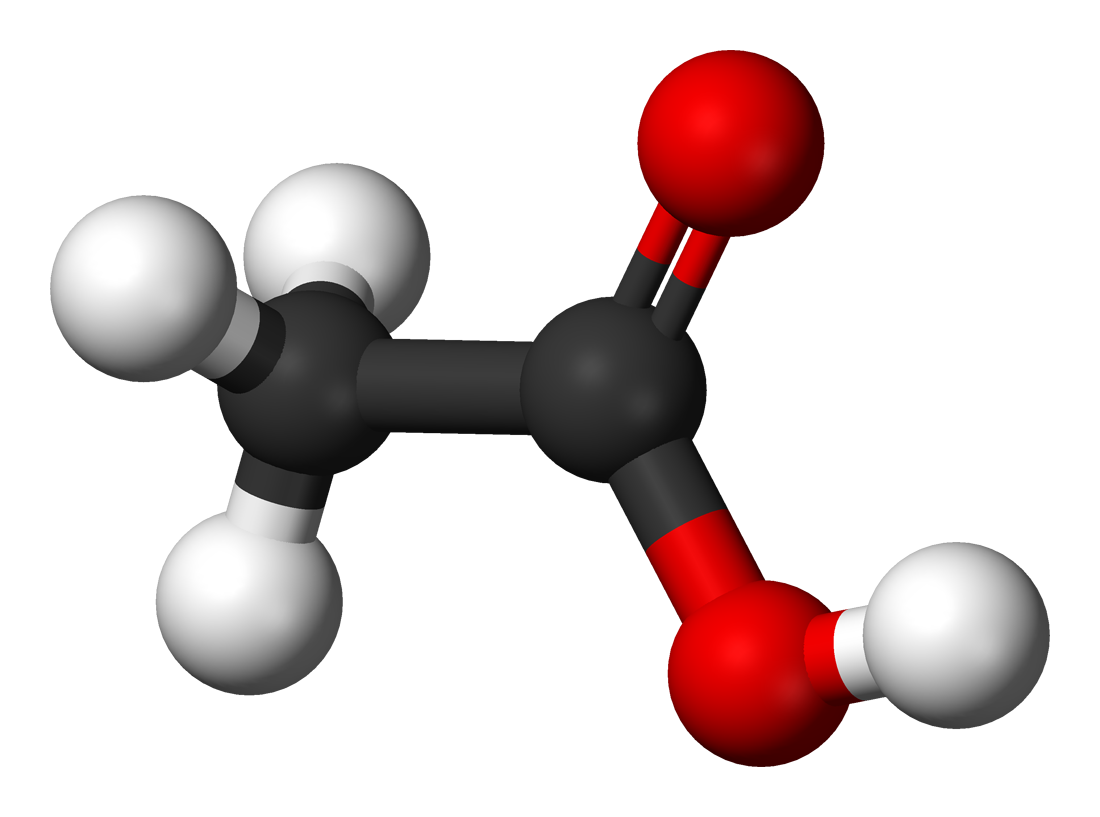

- Nutraceutical formulations, Formic acid, Dairy processing derivatives, Cryogenic gases, Anticorrosive coatings, Active pharmaceutical ingredients, Food preservatives, Caustic soda, Vaccines, Specialty chemicals, Injectable solutions, Acetic acid, Sulfuric acid, Resins, Biopharmaceutical products, Insulating oils, Nitric acid, Aseptic bioprocessing solutions, Hydrochloric acid, Flavor extracts, Hydrogen peroxide, Essential oils

- Steps before

- Pilot Testing, Scale-Up, Purification, Extraction, Filtration

- Steps after

- Evaporation, Distillation, Acid Recovery, Membrane Separation, Drying

- Input ingredients

- chemical substances, pharmaceutical compounds, fluids for processing, inert materials, corrosive agents

- Output ingredients

- processed chemicals, refined pharmaceutical products, purified fluids, corrosion-resistant materials

- Market info

- GMM Pfaudler is known for manufacturing glass-lined equipment, reactors, and engineered-to-order (ETO) solutions for the chemical, pharmaceutical, and allied industries, recognized for their innovation, quality, and global presence.

- Compliance,Standards

- ASME Code Section VIII, Div. 1

- Capacity

- 5 gallons to 15, 000 gallons

- Design Pressure

- High internal vessel and jacket pressures

- Temperature Suitability

- Lower temperature applications

- Material

- Glass-lined, 316L stainless steel

- Agitator Configuration

- 1-piece or 2-piece

- Sealing System

- INTERSEAL dry9000®

- Agitator Entry Technology

- Cryo-Lock technology

- Baffle System

- Flange-mounted baffle

- Sight Glass Assembly

- EZ Port

- Connection Type

- Tri-clamp sanitary fittings

- Batch vs. continuous operation

- Batch

- Pressure capability

- High internal vessel and jacket pressures

- Cryogenic applications

- To -150°F

- Temperature range

- Lower temperature applications

- Sealing system

- INTERSEAL dry9000™ sealing system

- Modular design

- 2-part or 1-part options

- Corrosion resistance

- Glass-lined and stainless steel

- Access

- Manway with sight glass

- Agitator options

- 1-piece or 2-piece design

- Jacket circulation

- Agitating nozzles

- Flexibility in reactor design

- Interchangeable RA and RS styles

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Yes

- Cleanability

- Yes

- Abrasion resistance

- No

- Density/particle size compatibility

- Wide range

- Cryogenic compatibility

- To -150°F

- ASME Boiler,Pressure Vessel Code

- Section VIII, Div. 1

- Body Flange

- 2-part with base vessel and cover (head)

- Reactor Shape

- 1-piece or 2-piece based on series

- Size Range

- 5 gallons to 15, 000 gallons

- Manway

- Spring-assisted cover with sight glass and protection ring

- Base Metal

- 316L Stainless Steel for RX series

- Agitator Type

- 1-piece or 2-piece with Cryo-Lock technology

- Design Options

- Flat or dished cover

- Jacket Type

- Conventional with agitating nozzles

- Reactor Layout

- Symmetrical top head layout for RA series

- Sight Glass Assembly

- EZ port with polished Inconel exterior

- Nozzle Arrangement

- Flange-mounted baffle

- Body Flange Design

- 2-piece (base vessel and cover)

- Base Metal

- 316L stainless steel

- Available Sizes

- 5 to 15, 000 gallons

- Agitator Type

- 1-piece or 2-piece with Cryo-Lock technology

- Jacket Pressure Capability

- High internal vessel and jacket pressures

- Sealing System

- INTERSEAL dry9000™

- Sight Glass Assembly

- EZ port with polished Inconel exterior

- Connection Type

- Tri-clamp sanitary fittings

- Agitator Styles

- Variety to achieve low level mixing