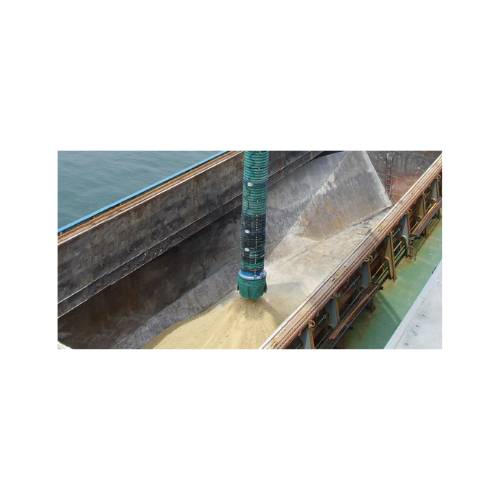

Telescopic loading bellows for bulk solids

Streamline your bulk material operations with high-capacity, dust-free loading solutions optimized for precision and efficiency, ensuring flawless loading into ships, barges, or stockpiles with minimal environmental impact.

Performs High-Capacity Loading and Dust Extraction

The ZQ Telescopic Loading Bellows from WAMGROUP offers a specialized solution for high-capacity, dust-free transfer of bulk solids. With an impressive capacity of 1,800 m³/h, it efficiently loads powders and granular materials into ships, barges, and stockpiles. Its internal cones and external bellows facilitate precise material channelling and effective dust extraction, maintaining cleanliness throughout the operation. The system is designed for harsh environments such as cement, lime, and mineral processing plants, ensuring quick, obstruction-free transfers with minimal wear due to its unique retraction mechanism supported by an electric winch. Customizable chute materials provide robustness and adaptability to different handling needs, while wireless remote control enables seamless integration into existing systems. The unit’s compatibility with centralized dust collectors highlights its operational efficiency for heavy industries, contributing to a cleaner, more efficient loading process.

Benefits

- Achieves dust-free operation, improving workplace safety and cleanliness.

- Facilitates rapid loading, minimizing operational downtime and boosting productivity.

- Customizable material options ensure durability and adaptability across various industrial applications.

- Electric winch-controlled retraction decreases maintenance needs and extends equipment lifespan.

- Seamless integration with existing dust collection systems enhances environmental compliance and efficiency.

- Applications

- Lime, Granular materials, Powders, Gypsum, Minerals, Refractory products, Cement

- End products

- Fine powder fillers, Silica sand, Gypsum plaster, Hydrated lime, Portland cement, Granular fertilizers, Alumina bricks

- Steps before

- Crushing, Mining, Quarrying, Screening, Micronizing

- Steps after

- Dust Collection, Stockpile Management, Material Transport

- Input ingredients

- powders, granular materials

- Output ingredients

- ship holds, barge holds, open stockpiles

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Capacity

- 1, 800 m3/h (1, 060 cfm)

- Inlet diameter

- 800 mm (32 in)

- Maximum extension

- 30 m (98.4 ft)

- Operating temperature

- -20 ~ 150 °C (-4 ~ 300 °F)

- Automation

- Electric winch controlled

- Loading Mechanism

- Telescopic

- Control Method

- Electric Winch

- Dust Control

- External Bellows for Dust Extraction

- Loading Capacity

- 1, 800 m3/h (1, 060 cfm)

- Temperature Range

- -20 ~ 150 °C (-4 ~ 300 °F)

- Automation Level

- Optional Wireless Remote Control

- Loading Type

- High Capacity, Dust-Free

- Bellows Retraction

- Controlled by Electric Winch

- Loading Environment

- Ships, Barges, Stockpiles

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- Available

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cleanability

- Easy

- Biological compatibility

- N/A

- Material type

- Powders / Granular materials

- Discharge application

- Ships / Barges / Stockpiles

- Inlet diameter

- 800 mm (32 in)

- Maximum extension

- 30 m (98.4 ft)

- Machine footprint

- Compact for high-capacity applications

- External lifting cables

- 3 off, not in contact with material flow

- Bellow retraction method

- Electric winch

- Operating temperature

- -20 ~ 150 °C (-4 ~ 300 °F)

- Discharge method

- Telescopic loading with dust extraction

- Control panel type

- Wireless remote control

- Fabrication materials

- Various chute and fabrication materials available

- Discharge method

- Bellows with internal cones for material flow and external bellows for dust extraction