Integrated packaging system for cement and building materials

Streamline your packing operations with a fully enclosed system that efficiently handles powdery, granular, and liquid products, ensuring precise bagging and sealing while maintaining a dust-free environment. Ideal for high-speed settings, it enhances productivity and reduces material waste.

Packs, Fills, Bags, and Seals Products

The INTEGRA® Series from Haver & Boecker is a fully automated packaging system designed for diverse industrial needs, including cement, building materials, and chemical products. It integrates all packaging functions within a dust-tight enclosure, streamlining bagging processes for powders, granules, liquids, and pasty products. Utilizing a modular design, it offers flexibility with options for valve bags and FFS (Form, Fill, Seal) tubular film bags, supporting production rates from 300 to 1,200 bags per hour.

The system incorporates advanced control technology with the MEC® 4.0 platform, allowing remote monitoring and analytics via the QUAT²RO® suite. The energy-efficient design features intelligent ventilation and lighting, coupled with Siemens TIA portal control for precision operations. Available with various filling modules tailored to product properties, the INTEGRA® can handle abrasive and corrosive materials with customizable material options. Its SEAL technology ensures secure closures, and the equipment’s modularity allows for scalable integration suited to your specific production line configuration. Compliance with industry standards and easy maintenance features, like automatic saddle height adjustment, enhance its operational reliability and sustainability.

Benefits

- Increases efficiency with fully automated, continuous operation.

- Ensures precise and clean packaging with dust-tight enclosure.

- Enhances flexibility with modular design for various product types.

- Optimizes performance with intelligent, remote monitoring and analytics.

- Reduces operational costs through energy-efficient control systems.

- Applications

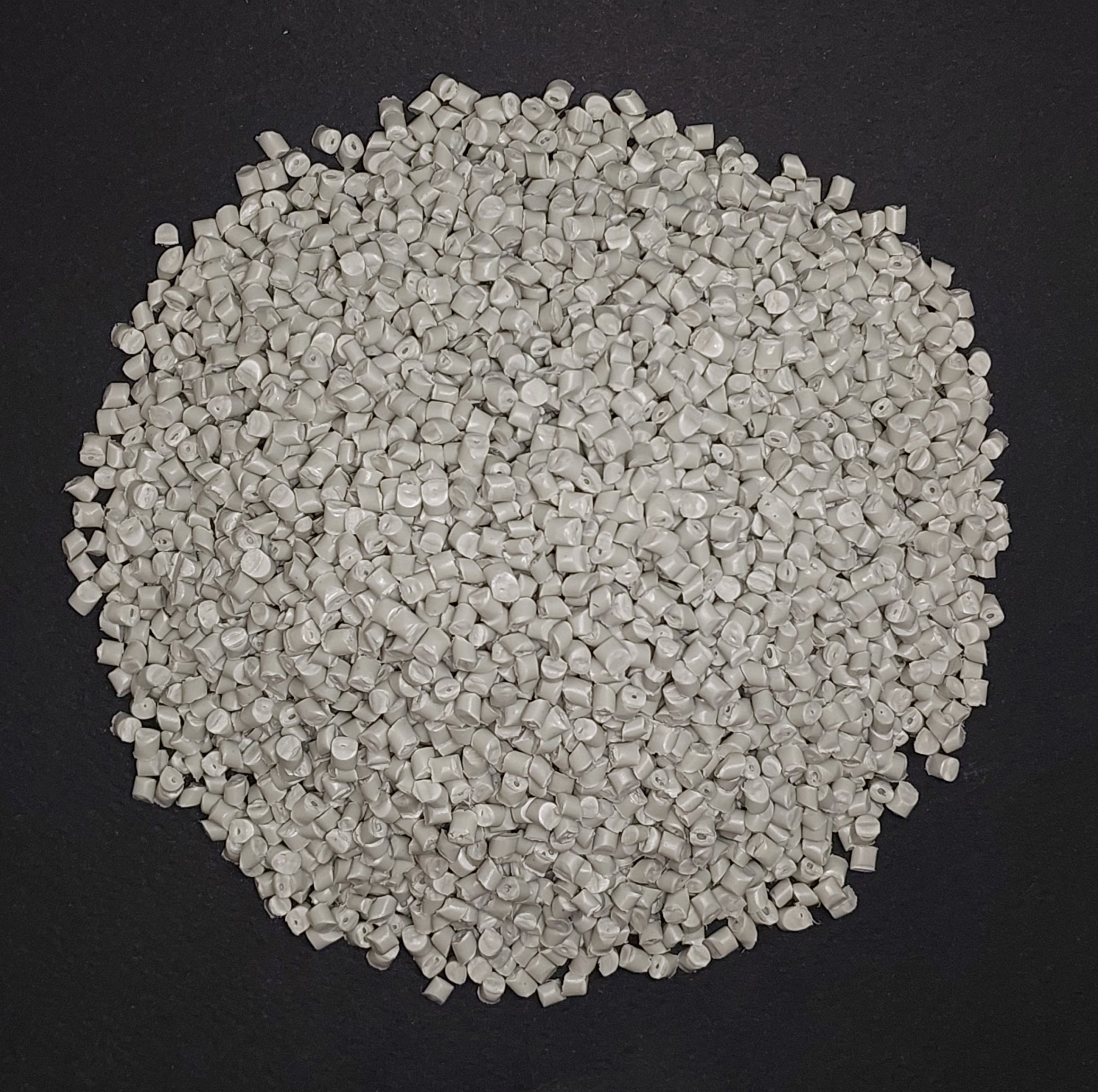

- Flour-type products, Building materials, Pasty products, Chemical products, Liquid products, Powder, Minerals, Granular products, Cement

- End products

- Detergent powders, Gypsum powder, Polypropylene granules, Mortar mix, Dry wall compound, Polyethylene granules, Industrial adhesive powders, Plaster of paris, Portland cement, Concrete additives, Sodium bicarbonate, Brick mortar, Toothpaste, Liquid detergents, Bentonite clay, Calcium carbonate powder, Fertilizer granules, Potassium nitrate, Juice concentrate

- Steps before

- Grinding, Mixing, Blending

- Steps after

- Packing, Bag Sealing, Product Weighing

- Input ingredients

- powder, granular products, flour-type products, building material, minerals, chemical products, liquid products, pasty products, fine powder, mixed products

- Output ingredients

- valve bags, FFS (Form, Fill, Seal) open-mouth bags, tubular film bags, 5 kg valve bags, film bags

- Market info

- Haver & Boecker is renowned for its expertise in manufacturing advanced industrial ETO equipment, specializing in material handling, packing, and screening technology for industries like mining, construction, and chemicals, known for innovation and quality.

- Bag type

- Valve / Tubular film

- Capacity

- 300–1, 200 bags/hour (5–40 bags/min)

- Automation

- Plug, Play

- Filling spouts

- 1 to 4

- Filling module

- Turbine (T-module) / Air (L-module)

- Dust enclosure

- Yes

- Bag closure

- SEAL technology

- Digital equipment

- Monitoring, remote, diagnostics

- Control technology

- Siemens TIA portal control

- Weighing electronics

- MEC 4.0

- Interior housing

- Fully automatic linear connector

- Filling method

- Form, Fill, Seal (FFS) / Valve filling

- Packaging speed

- 300 to 1, 200 bags/hour

- Bag type options

- Valve bags, FFS open-mouth bags

- Filling spouts

- 1 to 4 spouts

- Dust-enclosed housing

- Yes

- Plug,Play integration

- Yes

- Modular configuration

- Yes (T-module, L-module, etc.)

- SEAL technology for valve bags

- Yes

- Automation level

- Automatic handling

- Digital monitoring and diagnostics

- Optional

- Remote service capability

- Optional with QUAT²RO®

- Dust-tight packaging

- Yes

- Adjustable saddle height

- Automatic

- Control system

- MEC® 4.0 with Siemens TIA portal

- Ventilation control

- Intelligent system

- Lighting indicators

- Operational status

- Abrasion resistance

- Suitable for paper, woven PP, or PE

- Corrosive resistance (e.g. acids)

- Suitable for chemical products packaging

- Density/particle size

- Compatible with powder, flour-type, or granular products

- Cleanability

- Dust-tight housing for easy maintenance

- Machine footprint

- Compact, dust-enclosed housing

- Discharge method

- Bag discharge belt

- Filling spouts

- 1 to 4 filling spouts

- Bag type

- Valve / tubular film / FFS open-mouth

- Control panel type

- Siemens TIA portal control

- Control panel type

- Siemens TIA portal control

- HMI display type

- MEC® 4.0 operating display

- Filling module type

- VT/T-module (turbine) and VL/L-module (air)

- Bag type

- Valve bags / Tubular film

- Intelligent ventilation

- Optimum filling efficiency

- Lighting system

- Intelligent lighting for operating status

- Automatic saddle height adjustment

- For different bag lengths

- Remote monitoring

- QUAT²RO® remote service