Ring valves for industrial compressor systems

Optimize the efficiency and reliability of your gas compression processes with advanced ring valves designed for versatile applications, ensuring uniform wear and enhancing flow dynamics to withstand challenging environments.

Enhances Gas Compression Efficiency

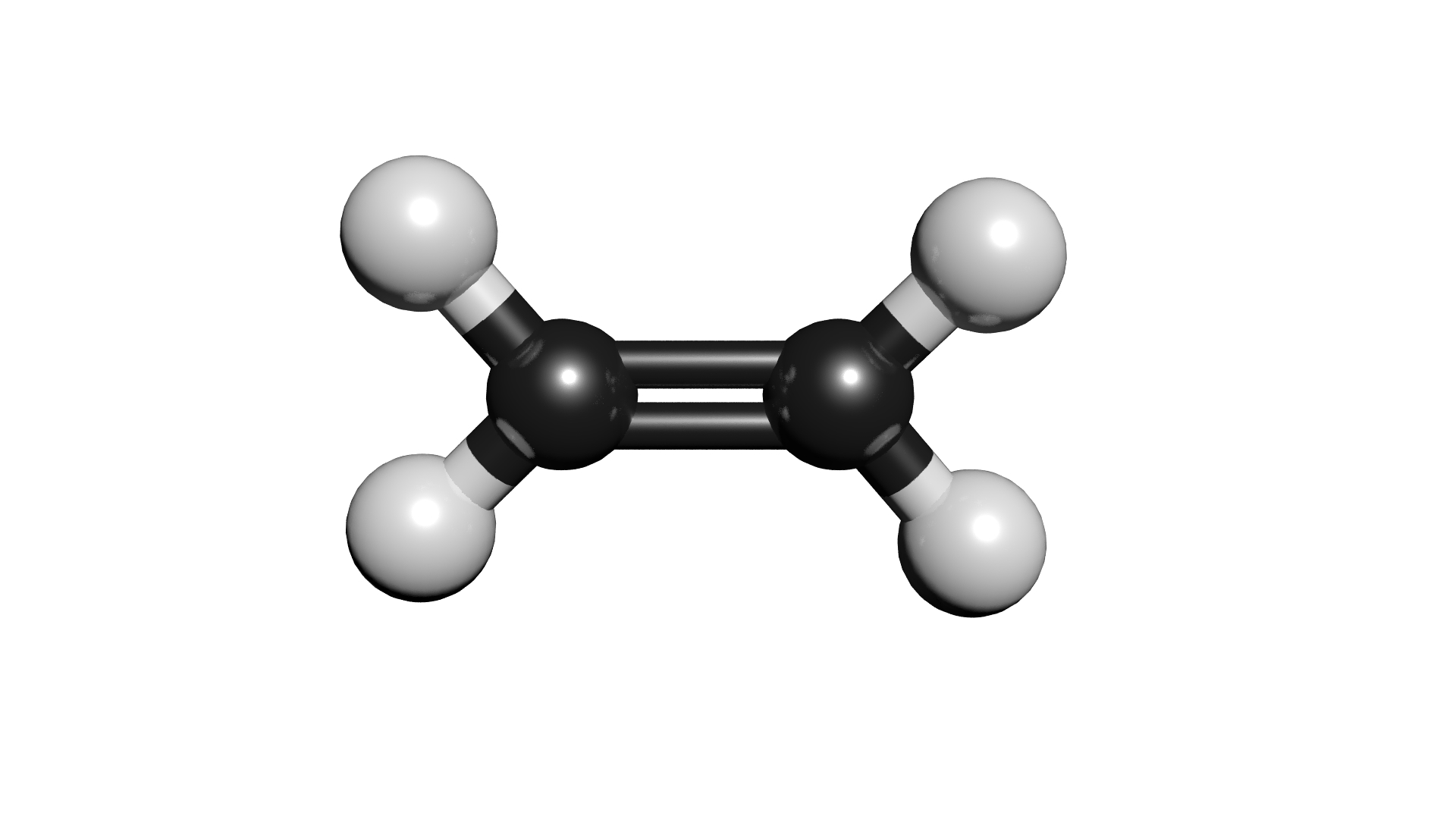

The BORSIG ZM ring valves are engineered to optimize gas compression across diverse applications, such as hydrogen, ethylene, and monomer gases. Featuring high-performance non-metallic valve rings in flat or convex forms, these valves promote uniform wear and a self-cleaning effect, essential for handling emissions and process gases in industries like oil and gas and petrochemicals. Their streamlined design enhances flow dynamics, offering superior performance in contaminated environments. The convex form increases effectiveness by improving aerodynamic characteristics under compression. These valves integrate seamlessly with reciprocating compressors for end-products like ammonia, urea, and polyethylene. They are suitable for high-performance and continuous operations, enhancing efficiency through easy retrofitting and machining on conventional lathes. Customization options and robust engineering support ensure these valves meet your specific plant requirements, providing durability and reliability in continuous use.

Benefits

- Ensures uniform wear and extended valve life with rotating non-metallic rings.

- Enhances processing efficiency under contaminated conditions through optimized flow dynamics.

- Lowers maintenance costs by integrating self-cleaning features.

- Adapts easily to existing setups with retrofitting capabilities.

- Supports diverse gas applications, improving flexibility across production lines.

- Applications

- Propylene, All gases, Hydrocarbons, Monomers, Ethylene, Emissions, Process gases, Nitrogen, Hydrogen

- End products

- Polyethylene, Ammonia, Polypropylene, Emission control systems, Synthetic rubber, Urea, Petrochemicals, Industrial chemicals, Fertilizers, Ethylene oxide

- Steps before

- Gas compression, Precompression treatment, Contaminant removal, Cooling

- Steps after

- Further compression stages, Gas distribution, Storage, Transportation

- Input ingredients

- compressor gases, contaminated environments, medium flow under compression

- Output ingredients

- uniform wear distribution, self-cleaning effect, aerodynamic characteristics

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Material Suitability

- All gases

- Valve Form

- Flat / Convex

- Valve Rotation

- Self-cleaning effect

- Wear Uniformity

- Very uniform wear

- Resistance to Liquid Hammers

- High

- Machining Compatibility

- Conventional turning lathe

- Aerodynamic Design

- Streamlined

- Suitability for Environment

- Contaminated environments

- Working mechanism

- Rotating valve rings

- Self-cleaning effect

- Yes

- Flow type

- Inline Continuous

- Handling of contaminated environments

- High suitability

- Resistant to liquid hammers

- Yes

- Aerodynamic characteristics

- Favourable

- Retrofitting ease

- Machinable on a conventional turning lathe

- Abrasion resistance

- Yes

- Corrosive resistance (e.g. acids)

- High

- Cleanability

- Good

- API Compliance

- API 618, API 11P, API 617, API 672

- ISO Certification

- ISO 13631

- Valve rotation feature

- Yes

- Valve ring type

- Flat / Convex

- Valve material

- Non-metallic

- Integration possibilities

- Machinable on conventional turning lathe