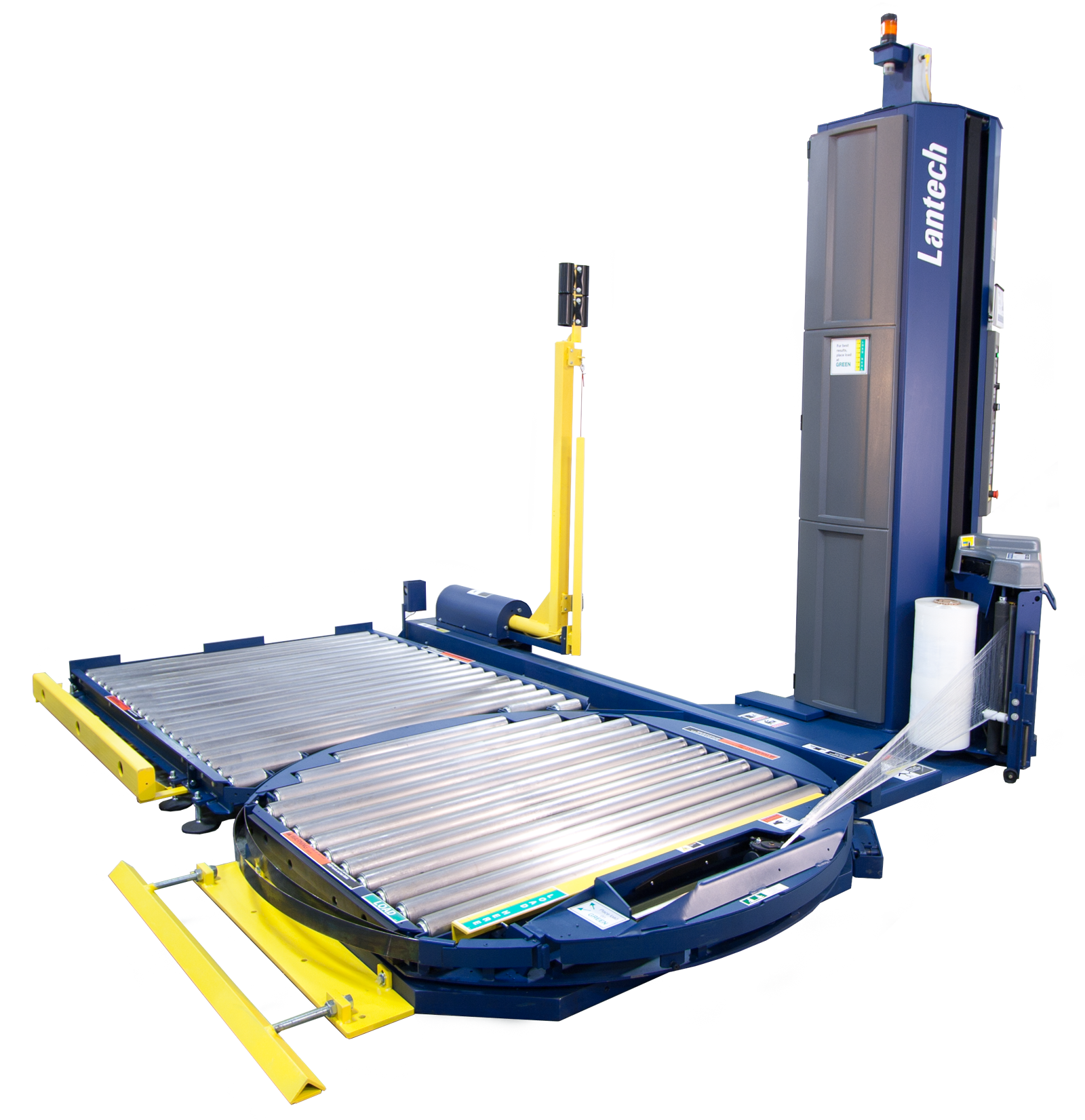

Semi-automatic turn-table stretch wrapper

For your most common stretch wrapping requirements, consider a semi-automatic turn-table to optimize your process.

Wrap tighter with less film on an easy to use turn-table

Lantech Q-series offers a broad range of turn-table stretch wrappers to suit your particular requirements. A turn-table is the most common stretch wrapping solution in the industry as it is so easy to manipulate the loads. Various options are developed by Lantech to adapt the wrapping process to your work environment:

Submit XT Cut and Clamp®

Keep your operator on the forklift. Reduce labor by 2 minutes per load. The XT Cut and Clamp catches the film at the end of the wrap cycle, cuts the film and holds it in place for the next cycle.

Auto Film Cut-off™

Save 30 seconds of labor per load. At the end of the cycle the film is automatically cut. This allows the operator to leave the machine and come back to a load that is ready for pick-up.

Submit EZ Weigh™ Integrated Scale

Eliminate double handling, weigh and wrap at the same time. When you know a pallet’s accurate weight you can avoid less-than-truckload fines and perform a final quality check. The EZ Weigh package has a low profile design and uses the same footprint as a standard Q Series stretch wrapper.

Pallet Grip®

Reduce the risk of in-transit damage, lock your load to the pallet. Every year, 20 million loads slide off their pallets resulting in $6 billion in damaged products. Pallet Grip rolls film into a tight cable and drives it down onto the pallet. The placement of the cable allows forks to pick-up the load without damaging the film.

Benefits

- Controls and film delivery system are within easy reach of operator

- Turntable support bearings are lubricated for life of machine

- Emergency stop button

- Stretch wrapper stops automatically if the film breaks

- Exclusive inteli-sensor sees a wide variety of colours and surface variations