Injected density stabilizer for pneumatic conveying

Optimize your dense phase pneumatic conveying with a stabilizer designed to enhance efficiency, reducing blockages and energy consumption while increasing throughput.

Optimizes Dense Phase Pneumatic Conveying

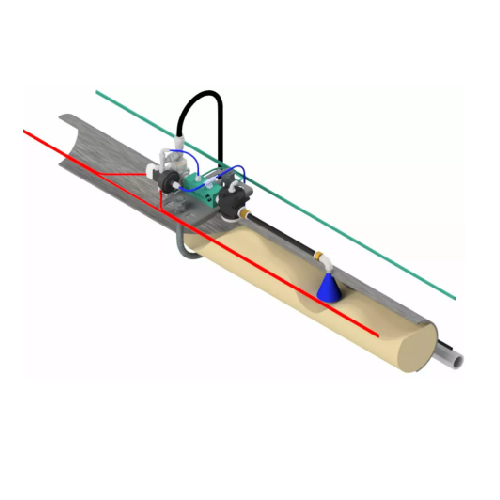

The Injected Density Stabilizer – CONiQ Control IDS from Schenck Process revolutionizes dense phase pneumatic conveying by addressing common issues with traditional air injection boosters. It self-optimizes air flow to manage material plugs, minimizing blockages and enhancing efficiency in processes involving powders and granules.

Designed for flexible installation across existing systems, it supports industries like chemicals, plastics, and metals, conveying products such as industrial chemicals and metal powders. It can handle material velocities between 2 to 12 m/s, while significantly reducing energy consumption, often by up to 40%, and enhancing conveying rates up to 30%.

This energy-efficient solution eliminates excessive plugging and reduces pipeline wear, thanks to its modular design that simplifies maintenance. With easy ‘plug and play’ functionality, no external signals or electronics are needed, minimizing downtime. Whether used for new installations or as an upgrade, the CONiQ Control IDS provides tangible economic benefits through reduced power consumption and increased throughput.

Benefits

- Increases production rates by up to 30%, improving overall process efficiency.

- Cuts energy costs with up to 40% reduction in power consumption.

- Minimizes downtime and maintenance with reduced pipeline blockages and system wear.

- Offers flexible integration with 'plug and play' setup for seamless upgrades or installations.

- Supports diverse material applications, handling challenging granular materials with ease.

- Applications

- Chemicals, Food, Geldart class b materials, Detergents, Metals, Plastics, Salt, Granular powders

- End products

- Metal powders, Snack powders, Industrial chemicals, Table salt, Laundry detergents, Plastic pellets

- Steps before

- Grinding, Material Preparation, Material Blending

- Steps after

- Packing, Storage, Quality Assurance

- Input ingredients

- dry powders, coarse powders, granular powders, Geldart Class B materials, Salt, raw materials

- Output ingredients

- conveyed materials, increased transfer rate, optimized conveying process

- Market info

- Schenck Process is known for its expertise in material handling, weighing, feeding, and automation solutions. The company has a strong reputation for delivering high-quality engineered-to-order equipment for diverse industries, backed by innovative technology and customer-centric service.

- Air speed

- 2-12 m/s

- Conveying capacity

- 20% increase potential

- Conveying distance

- Up to 150m (>150m can be considered)

- Energy consumption reduction

- Up to 40%

- Conveying rate increase

- Up to 30%

- Automation

- Self-optimizing, pneumatic, 'plug and play'

- Material compatibility

- Geldart Class B materials

- Sustainability

- Reduced energy costs

- Working Mechanism

- Self-optimizing air technology

- Plug Detection

- Automatic between injection points

- Energy Efficiency

- Energy-saving functionality

- Automation Level

- Fully pneumatic with 'plug and play'

- Installation Type

- Retrofittable/ New Installations

- Air Flow Regulation

- Variable, adaptable along the pipeline

- Error Reduction

- Reduces blockages and bottlenecks

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Material type

- Dry / Coarse / Granular

- Machine footprint

- Compact

- Discharge method

- Plug and play functionality

- Control panel type

- Pneumatic with no external activation signal or electronics

- Control panel type

- HMI with PLC integration

- Integration possibilities

- Compatible with existing systems

- Modular design

- Commonality of components

- Installation type

- Plug and play

- Retrofitting capabilities

- Sometimes retrofitted on existing systems

- Air injection control

- Self-optimizing

- System compatibility

- Works with non-Schenck systems