Integrally geared centrifugal compressors for process gases

Optimize your production efficiency with our integrally geared centrifugal compressors, designed for high-speed, continuous gas processing applications that demand reliable compression performance in complex industrial settings.

Compresses Process Gases Efficiently and Continuously

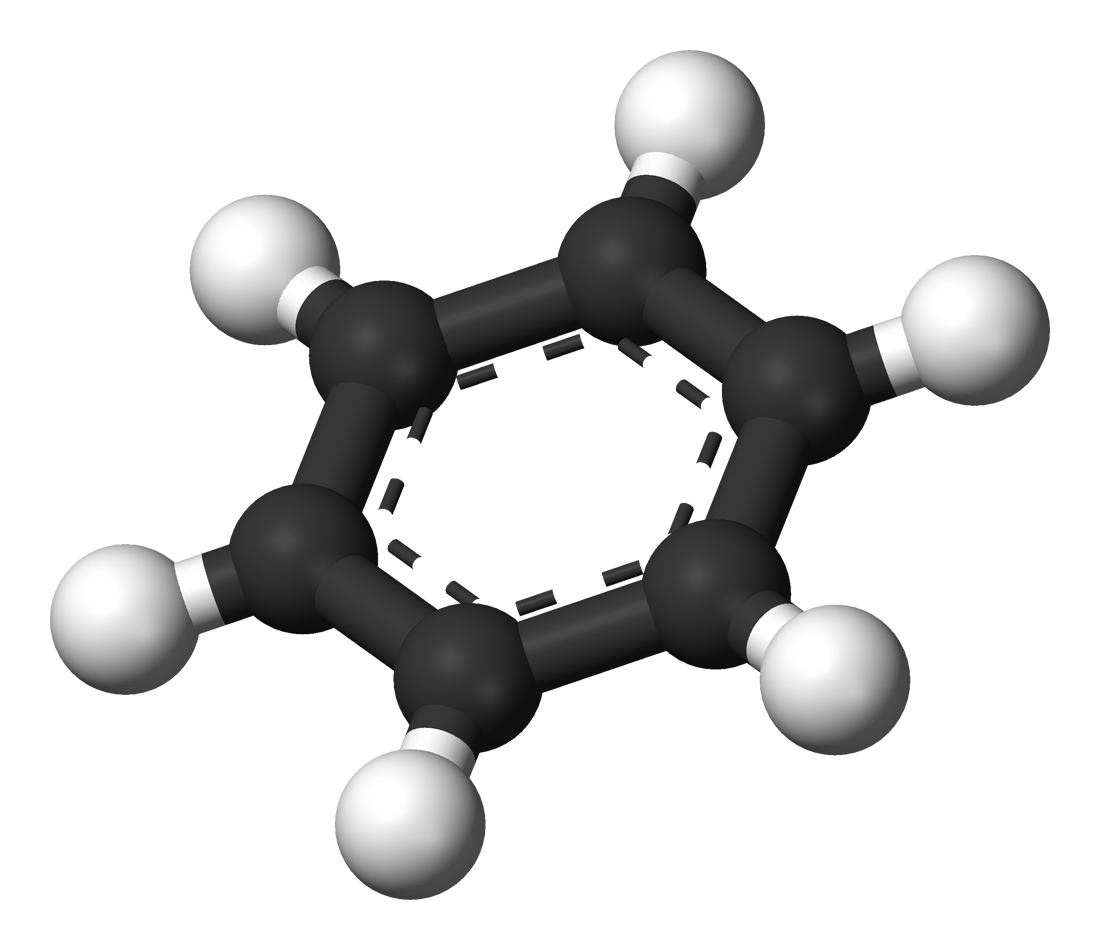

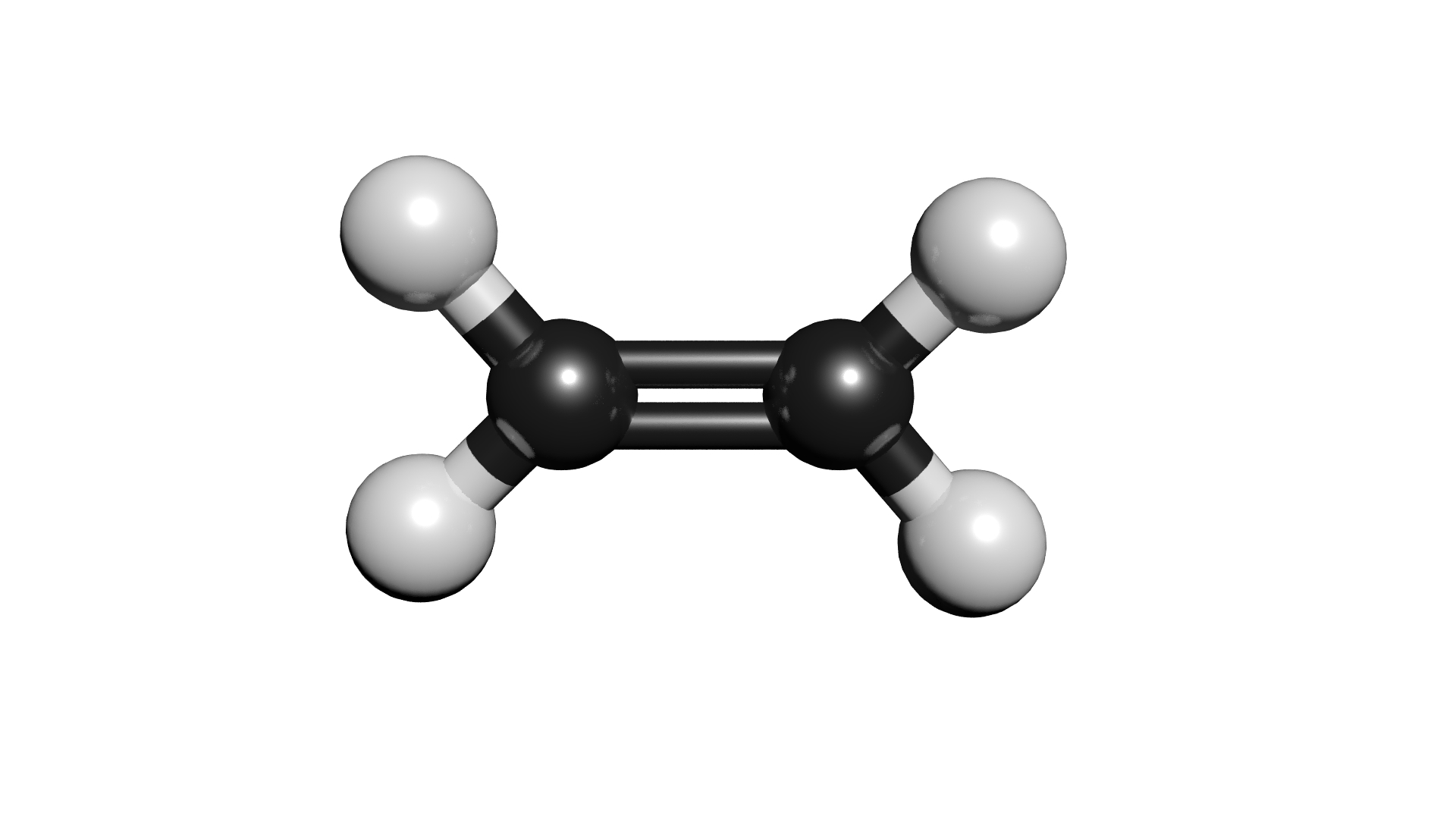

The Integrally Geared Centrifugal Compressors API 617 and 672 by BORSIG ZM Compression GmbH efficiently handle a wide range of industrial gas compression needs. These multi-stage compressors are engineered for pulsation-free, oil-free fluid compression, utilizing a cutting-edge design that includes speed variation and cooling between each stage. Primarily used in petrochemical, refinery, gas treatment, fertilizer, power plant, and steel industries, they support the production of ethylene, propylene, ammonia, methanol, and more. Capable of reaching discharge pressures up to 200 bara and flow capacities up to 300,000 m³/h, these compressors are designed for seamless integration in high-throughput environments. They are API compliant (617 and 672), ensuring reliability and performance, with an oil system designed to the manufacturer’s standard or API 614. Featuring inlet guide vane control and axial flow blades, they offer exceptional efficiency and long operational life. Customization is available to meet specific operational requirements, and each unit is backed by BORSIG’s world-class engineering support and service network.

Benefits

- Enhances operational efficiency with pulsation-free, continuous compression.

- Ensures energy savings through optimized speed variation and stage-specific cooling.

- Complies with industry standards (API 617 and 672) for reliable and robust performance.

- Enables prolonged operation with minimal maintenance due to oil-free compression.

- Integrates seamlessly into existing production lines, supporting diverse industrial applications.

- Applications

- Steel industry, Fertilizer, Petrochemicals, Power plants, Gas treatment, Refineries

- End products

- Propylene, Electrical power, Methanol, Steel, Ammonia, Phosphates, Benzene, Syngas, Ethylene, Iron, Urea, Lubricants, Nitrogen, Gasoline, Hydrogen, Diesel

- Steps before

- Purification, Gas treatment, Pre-compression assessment, System calibration

- Steps after

- Cooling, Power generation, Product recovery, Quality inspection

- Input ingredients

- Output ingredients

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Power ranges

- Up to 25, 000 kW

- Discharge pressure

- Up to 200 bara

- Capacity/flow*

- Up to 300, 000 m³/h

- Stages

- Up to 8 stages

- Driver type

- Steam turbine, gas turbine, electric motor

- API compliance

- API 617 and 672

- Oil system design

- API 614

- Cooling

- Between each stage

- Inlet guide vane control

- Yes

- Axial flow

- Into blades

- Operation

- Pulsation-free, oil-free fluid

- Uninterrupted operation

- Long duration

- Working Mechanism

- Integrally geared centrifugal

- Stages

- Up to 8 stages

- Driver Type

- Steam turbine / Gas turbine / Electric motor

- Cooling Method

- Intercooling between stages

- Control System

- Inlet guide vane control

- Compliance

- API 617 and 672

- Flow Type

- Axial flow into blades

- Operation type

- Continuous pulsation-free operation

- Automation Level

- Customized as per requirements

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact/Skid-mounted

- Number of Stages

- Up to 8 stages

- Driver Options

- Steam turbine / Gas turbine / Electric motor

- Process Gas Lines

- Integrally Geared

- Cooling Method

- Cooling between stages

- Control System

- Inlet guide vane control

- Power source options

- Steam turbine / Gas turbine / Electric motor

- Stage customization

- 1–8 stages

- Control system

- Inlet guide vane control

- Cooling method

- Cooling between each stage

- Compliance with design standards

- API 617, API 672

- Oil system design

- API 614 / Manufacturer's standard