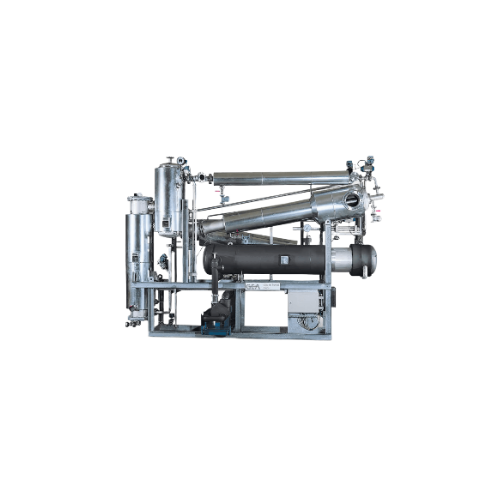

Product driven steam jet vacuum systems for polyester and nylon production

Optimize your vacuum processes with product-driven steam jet systems, ensuring seamless operations in polyester and nylon production while minimizing water infiltration and energy consumption.

Creates and Maintains Vacuum for Nylon and Polyester Production

GEA’s Product Driven Steam Jet Vacuum Systems leverage proven jet pump technology to address the unique demands of polyester and nylon production. These systems utilize product vapor to maintain vacuum during key processes, such as evaporation and crystallization, reducing water contamination and enhancing energy efficiency. With the capability to handle both gas and vapor types, they integrate seamlessly into various industrial settings, including chemical, pharmaceutical, and environmental management. The systems feature low-maintenance designs without moving parts, offering virtually unlimited lifespans with appropriate material selection, including options for corrosion-resistant materials. Customization options enable adaptation to specific production requirements, supported by engineering expertise from GEA. Ideal for continuous or manual operations, these vacuum systems are essential for optimizing fiber and yarn quality in high-demand applications.

Benefits

- Ensures high-quality fiber production by minimizing water contamination through product vapor-driven operation.

- Reduces energy costs with efficient use of process vapors as motive medium.

- Virtually maintenance-free due to lack of moving parts, saving on maintenance labor and costs.

- Adaptable to various industrial environments with material customization options for corrosion resistance.

- Provides long-lasting service life, ensuring continuous operation and reliable performance.

- Applications

- Polyester, Nylon

- End products

- Polyester fibers, Nylon fibers, Polyester yarns, Nylon yarns

- Steps before

- Heat recovery, Evaporating, Distillation, Crystallization, Deodorization

- Steps after

- Cooling, Degassing, Drying, Condensate reuse

- Input ingredients

- water vapor, product vapor, motive steam

- Output ingredients

- condensate, motive steam condensate

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Vacuum Type

- Steam Jet Vacuum

- Motive Medium

- Product Vapor/Water Vapor

- Condensate Handling

- Re-evaporation/Direct Use

- Materials of Construction

- Various Materials

- Maintenance

- Maintenance-free

- Energy Requirement

- Low for Organic Vapors

- Working Mechanism

- Jet pump technology

- Evaporation medium

- Product vapor / Water vapor

- Water Ingress Control

- No water entry required

- Operation Environment

- Virtually all situations

- Automation level

- Manual / Automatic

- Energy Efficiency

- Lower energy requirement with organic vapors

- Condensate Management

- Reuse / Re-evaporation

- Installation

- Quick and easy

- Maintenance Requirement

- Low / Maintenance-free

- Lifetime

- Almost unlimited

- Material of Construction

- Various including corrosion-resistant materials

- Footprint

- Compact design adaptable to various installations

- Shape and Size

- Customizable based on plant requirements

- Discharge Method

- Motive steam re-evaporation

- Control panel type

- HMI / PLC / SCADA

- Material of Construction

- Stainless Steel / Graphite

- Integration possibilities

- Seamless with existing systems

- Installation flexibility

- Horizontal / Vertical setup