Disc mill for industrial laboratory grinding

Streamline your sample preparation with a robust disc mill designed for precise grinding and reproducible results, ideal for reducing medium-hard, hard, or brittle materials to a fine powder in laboratories and pilot plants.

Grinds and Crushes Medium-Hard to Hard Materials

The Disc Mill DM 200 from Retsch is engineered to deliver consistent and precise grinding for laboratory and pilot plant operations. Leveraging a robust design, it operates efficiently under diverse conditions, making it ideal for applications in fields such as metallurgy, ceramics, and electronics. Its distinctive mechanism consists of two vertical, meshing grinding discs, where one rotating disc applies pressure and friction against a fixed counterpart. This method ensures thorough preliminary and fine crushing of medium-hard to hard materials, with adjustable gap widths between 0.05 to 5 mm for optimal control over particle fineness.

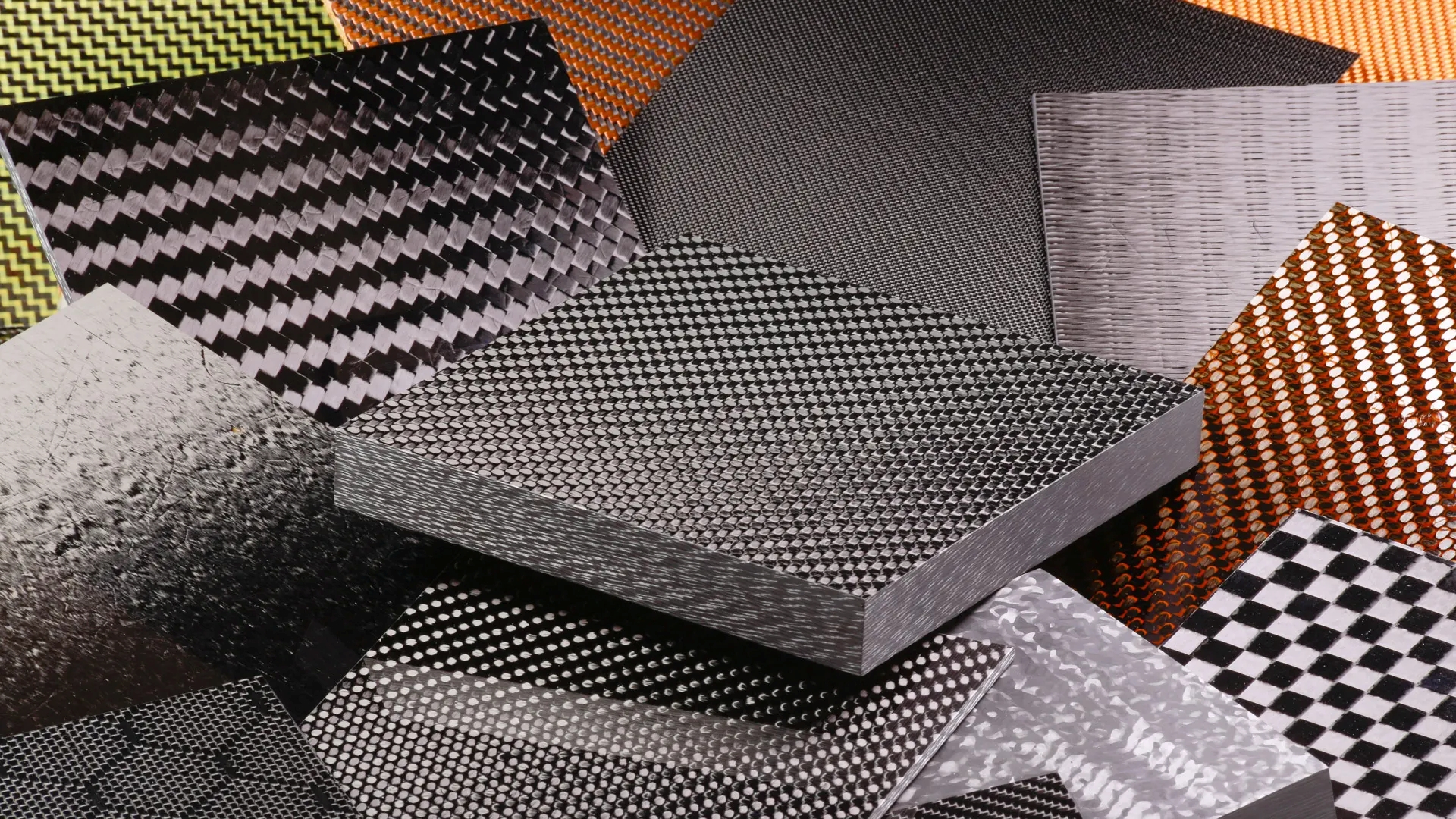

Capable of processing a broad range of materials—from bauxites and cement clinker to ores and metals—the DM 200 supports a variety of industrial and research applications. Its capacity is augmented by durable grinding discs available in materials like zirconium oxide and tungsten carbide for contamination-free processing. The integrated dust extraction connection minimizes airborne particulates, enhancing operational safety and cleanliness.

The DM 200 features a continuous adjustment capability that allows real-time monitoring and alteration of gap settings through an observation window, ensuring operational flexibility. Designed for integration into existing production lines, it operates with a 1.5 kW, 3-phase geared motor, supporting various voltages, and offers an IP 55 protection rating, confirming its suitability for demanding environments. With its straightforward maintenance, durable construction, and precision engineering, the Disc Mill DM 200 stands as a critical asset for achieving high-quality material processing.

Benefits

- Ensures consistent product quality with precise, adjustable grinding settings.

- Minimizes operational interruptions with easy cleaning through a hinged grinding chamber.

- Extends equipment lifespan using reversible rotating disc direction.

- Enhances worker safety and cleanliness with integrated dust extraction compatibility.

- Accommodates diverse application needs with a range of durable, contamination-free grinding disc materials.

- Applications

- Chemicals, Ceramics, Metal powders, Metallurgy, Construction materials, Geology, Ores, Soils, Waste processing, Glass, Plastics, Minerals, Electronics, Engineering materials, Slag

- End products

- Mineral supplements, Electronic component substrates, Metallic slag compounds, High-performance concrete, Agricultural soil amendments, Powdered metallurgy components, Advanced ceramic tiles, Recycled construction aggregates, Reinforced glass panels, Ore concentrates

- Steps before

- Sample Preparation, Crushing, Purification

- Steps after

- Quality Control, Analysis, Packaging

- Input ingredients

- bauxite, cement clinker, chalk, chamotte, coal, coke, concrete, construction waste, dental ceramics, dried soil samples, drilling cores, electrotechnical porcelain, ferro alloys, glass, granite, gypsum, hydroxyapatite, ores, quartz, sewage sludge, sintered ceramics, slag, soils, steatite

- Output ingredients

- preliminary crushed material, fine comminution material, contamination free grinded material

- Market info

- Retsch is renowned for manufacturing high-quality laboratory equipment, specializing in milling, sieving, and assisting technologies for sample preparation and characterization, known for precision, reliability, and innovation in the scientific and industrial laboratory markets.

- Speed at 50 Hz

- 440 min-1

- Speed at 60 Hz

- 528 min-1

- Material feed size

- < 20 mm

- Final fineness with hardened steel discs

- 50 µm

- Final fineness with tungsten carbide or zirconium oxide discs

- 100 µm

- Drive power

- 1.5 kW

- Electrical supply data

- 3-phase

- Protection code

- IP 55

- Dimensions

- W x H x D

- Net weight

- ~ 140 kg

- Gap width setting

- Continuous, 0.05 - 5 mm

- Collector capacity

- 2.5 l

- Rotating direction

- Doubling the life time of the discs by changing the direction

- Material of grinding tools

- Zirconium oxide, hardened steel, tungsten carbide, manganese steel

- Working Mechanism

- Pressure and friction

- Rotation Speed

- 440 min-1 (528 min-1 at 60 Hz)

- Gap Width Setting

- Continuous, 0.05 - 5 mm

- Automation Level

- Manual adjustment

- Cleaning Method

- Easy hinged chamber for manual cleaning

- Operation Environment

- Laboratories and pilot plants

- Batch vs. Continuous Operation

- Batch

- Cleanability

- Easy cleaning with hinged grinding chamber

- Density/particle size

- Medium-hard, hard, brittle materials

- Machine footprint

- 440 x 400 x 870 mm

- Discharge method

- Receiver collection

- Net weight

- ~ 140 kg

- Control panel type

- Continuous adjustment

- Grinding disc material options

- Zirconium oxide, hardened steel, tungsten carbide, manganese steel

- Collector capacity

- 2.5 l

- Continuous gap width adjustment

- 0.05 - 5 mm

- Rotating direction

- Changeable to double disc life