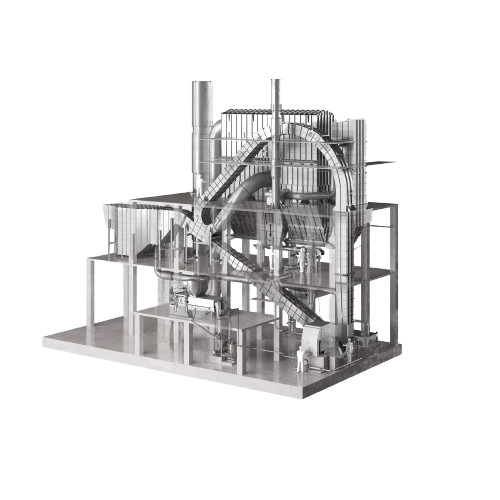

Industrial ring dryer for efficient particle processing

Control particle size and drying efficiency with precise recirculation and classification, ensuring optimal product quality and reduced energy consumption for continuous high-speed operations.

Controls Drying, Classifies, and Manages Particle Size

The GEA Ring Dryer is a versatile drying solution from GEA, adept at handling a wide array of materials with precision and efficiency. It integrates a unique manifold system and optional disintegrator mills to control residence time and particle size, ensuring optimized drying and product consistency. This industrial dryer is ideal for applications across the food, chemical, mineral, and plastics industries, effectively processing materials ranging from cornflakes and muesli base flakes to PVC powder and superabsorbent polymers.

With the ability to handle varied product types like powders, granules, slurries, and cakes, the GEA Ring Dryer supports continuous, high-speed operations. It accommodates custom integration into existing production lines, offering options for open circuit or inert atmosphere drying, and ensures energy efficiency by minimizing required airflow and fan power. The system’s design is customizable, allowing for material-specific configurations, such as stainless steel construction for enhanced corrosion resistance. Additionally, GEA provides comprehensive engineering support to tailor the dryer to your specific processing needs, helping maintain compliance with industry standards and simplifying cleaning with designed options for minimal downtime.

Benefits

- Enhances product quality with precise particle size and moisture control.

- Reduces energy consumption through efficient recirculation and airflow management.

- Optimizes processing flexibility for a wide range of materials and industries.

- Minimizes risk of thermal damage to heat-sensitive products.

- Streamlines integration into existing production lines with customizable configurations.

- Applications

- Food, Chemicals, Thermally sensitive materials, Organic fertilizers, Animal feeds, Sludges, Soy fibre, Waste products, Plastics, Modified starches, Minerals

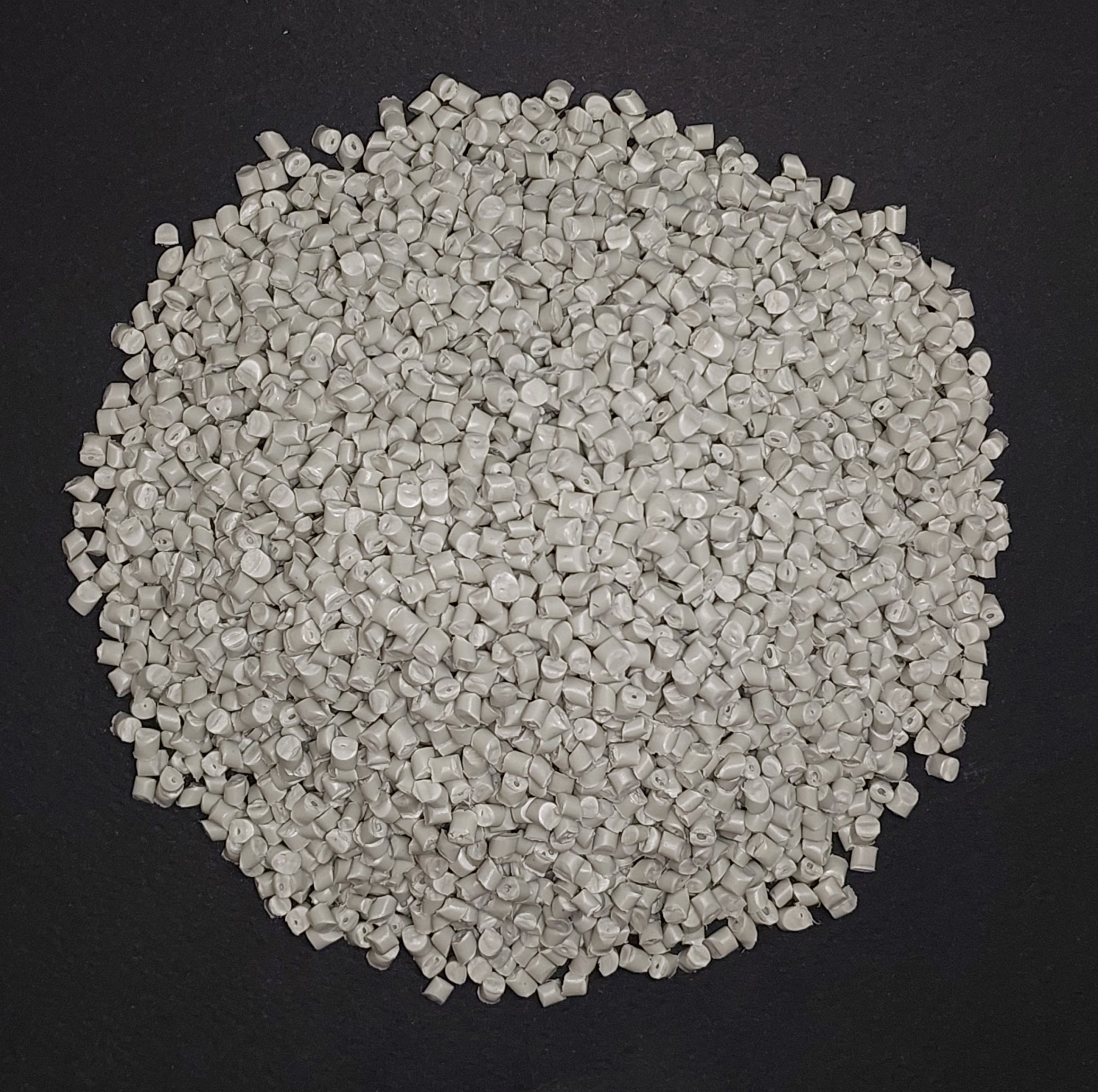

- End products

- Muesli base flakes, Modified starch powders, Cornflakes, Gelatin, Polypropylene granules, Fertilizer granules, Powdered sugar, Bone meal, Heat-sensitive pharmaceutical excipients, Isolated soy protein, Activated sludge, Superabsorbent polymers, Granola, Sewage sludge pellets, Animal protein meal, Instant coffee, Organic compost, Pvc powder

- Steps before

- Grinding, Mixing, Pre-dehydration, Pulverizing

- Steps after

- Cooling, Packaging, Moisture adjustment, Quality control

- Input ingredients

- powders, cakes, granules, flakes, pastes, gels, slurries, sticky materials, viscous products, wet feed

- Output ingredients

- drier product, high quality dried materials, dried products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Residence Time

- Adjustable

- Particle Size Control

- Precise/Adjustable

- Exhaust Temperature

- Controlled

- Feed Type

- Powders / Cakes / Granules / Flakes / Pastes / Gels / Slurries

- Manifold Type

- Single or Multi Classification Blades

- Operation Atmosphere

- Open Circuit / Partial Gas Recycle / Inert Atmosphere

- Drying Method

- Centrifugal Force Recirculation

- Disintegrator Mills

- Available

- Feed Introduction

- Reduced Inlet Temperature

- Back-Mixing System

- Available for Slurries, Pastes, Sticky Materials

- Energy Efficiency

- High

- System Integration

- Flexible

- Integrated manifold system

- Selective recirculation

- Particle size control

- Disintegrator mills

- Residence time control

- Centrifugal forces

- Energy efficiency

- Extended residence time

- Automation level

- PLC / SCADA

- Inert atmosphere operation

- Yes / No

- Batch vs. continuous operation

- Continuous

- Flexibility in feed types

- Powders / Pastes / Slurries

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Manifold Type

- Single or Multi-classification

- Control panel type

- PLC / HMI integration

- Discharge method

- Automatic / Manual

- Feed system

- Back-mixing / Buffer hopper

- Material Recirculation System

- Manifold / Internal classifier

- Integration with Dewatering Systems

- Yes

- Disintegrator/Disperser Options

- Various choices available

- Extrusion Systems

- For viscous products