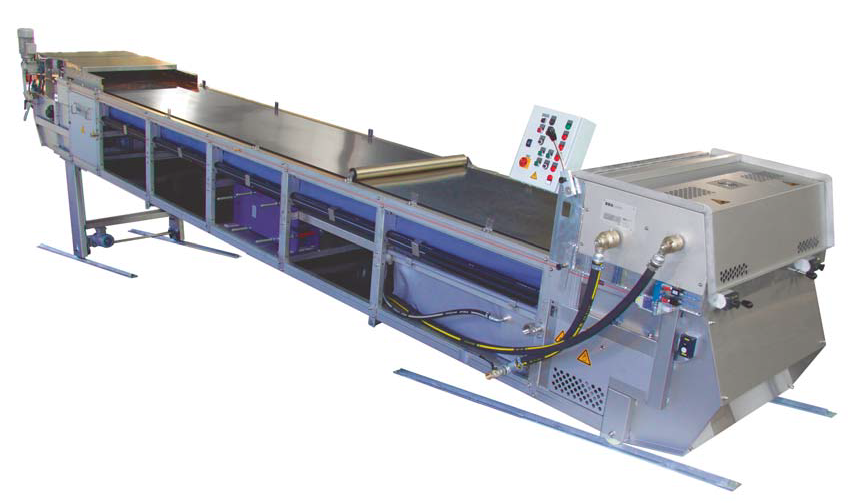

Steel belt cooler for hot melt extrusion

For producing high volumes of extruded hot melt product a flexible, high capacity solution is required. High performance steel belt coolers with a wide range of options and configurations will provide the optimum solution for larger scale extrusion requirements.

Stainless steel hot melt belt cooler for high capacity extrusion

The BBA Innova CCn is a flexible belt cooling solution for large volume hot melt extrusion. The product to be cooled down is extruded into a film and carried on a steel belt. A water spraying system underneath the belt cools the steel belt with the product on top

The CCn is built on modular sub-assemblies, meaning configuration can be tailored to your precise requirements, including a wide variety of belt-widths, crusher units, cooling calendar, and optional closed-loop with heat exchanger.

Fully adjustable speed allows perfect synchronization between the cooling calendar and belt for optimum cooling for specific hot melt masses.

The BBA Innova CCn has been specifically designed for easy and rapid clean down, reducing downtime to a minimum on product changeover.

Benefits

- Modular approach means flexibility to meet your exact requirements

- High volume throughput, up to 3,200kg per hour, speeds up your production

- Easy to clean and maintain, minimises your downtime

- Wide range of options can be retrofitted as your requirements change in the future