Continuous ploughshare mixer for diverse industrial applications

Enhance mixing efficiency and achieve precise particle control across varied industrial applications with a continuous process. Ideal for high-throughput production lines needing consistent product homogeneity and adaptable granulation capabilities.

Mixes, Coats, and Granulates Diverse Industrial Materials

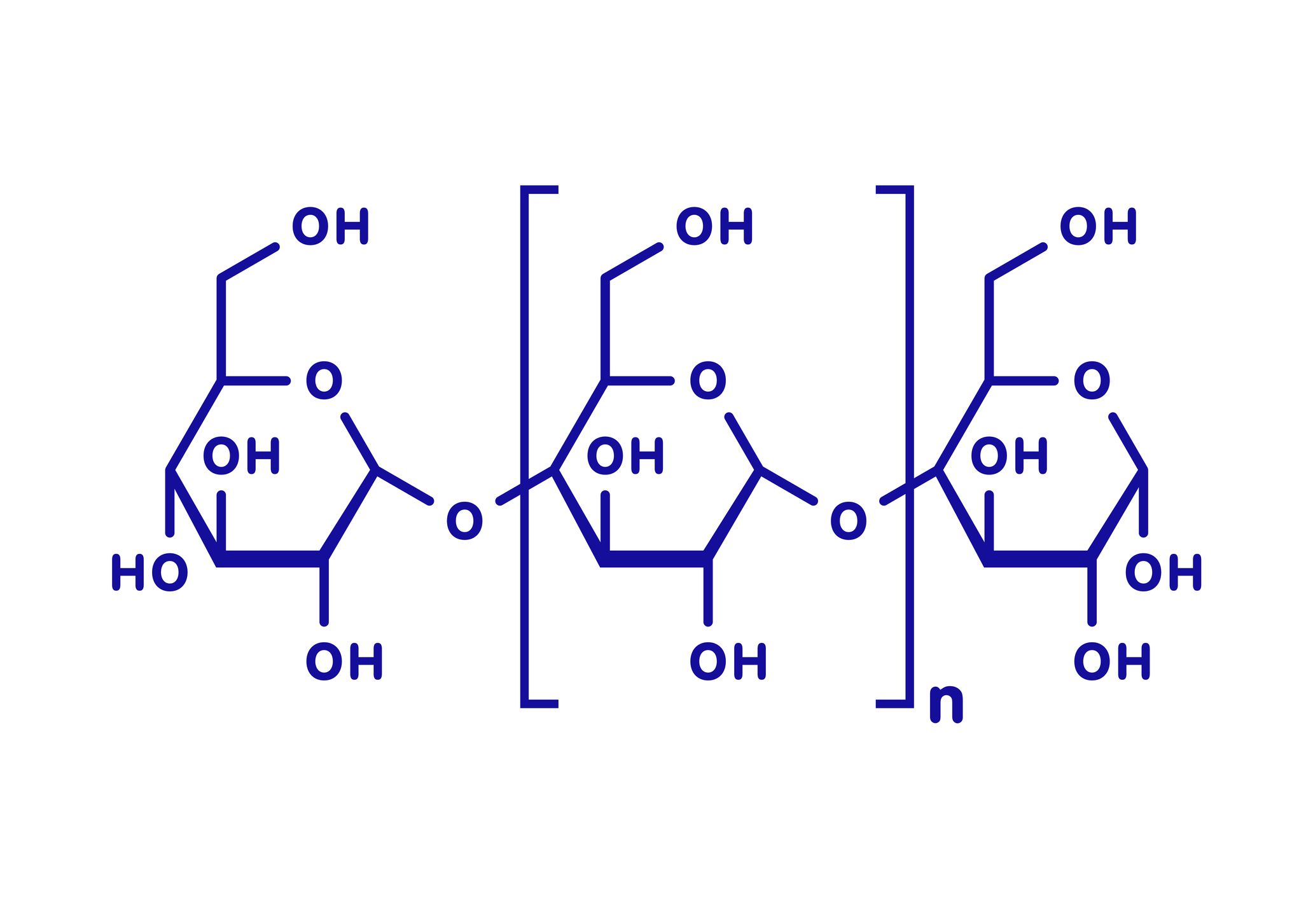

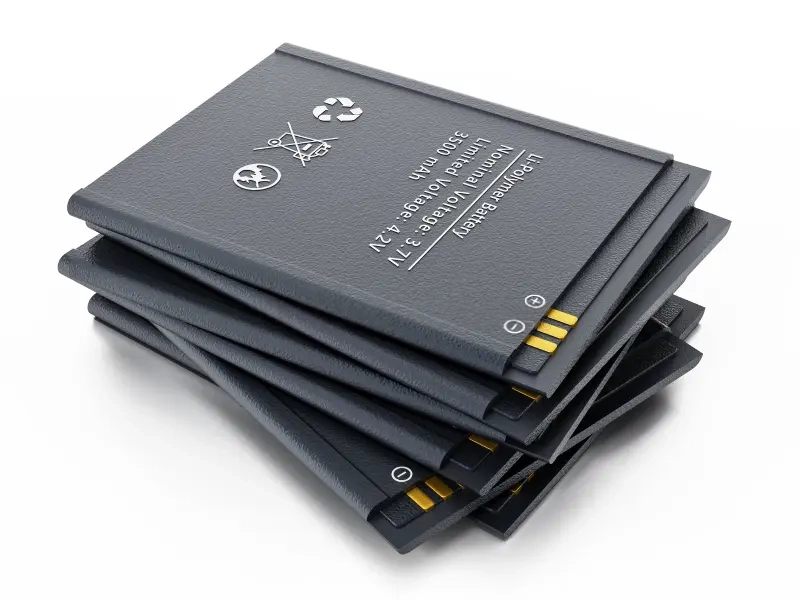

The Ploughshare® Mixer from Lödige Maschinenbau offers unparalleled flexibility and efficiency for continuous industrial material processing. Utilizing a mechanical fluid bed mixing process, it guarantees exceptional homogeneity, enabling high-throughput operations across industries such as building materials, chemicals, plastics, and metallurgy. This mixer is adept at handling solids, liquids, powders, and granules, effectively integrating into your production line to mix, dry, coat, or granulate products including ready-mix cement, epoxy resins, and battery masses.

With a capacity to operate efficiently at filling levels between 20% and 50%, this machine maintains consistency in mixing quality. Optional chopper installations enhance turbulence, aiding in the dispersion of fine particles and agglomerates. PLC controls provide seamless automation, while diverse material construction options, including stainless steel, ensure compatibility with various industrial chemicals. This mixer supports advanced features like liquid addition systems for granulation and coating applications, ensuring precise process control.

Lödige’s engineering support offers customizable solutions tailored to your specific operational demands and industry standards, ensuring the Ploughshare® Mixer not only meets but exceeds your production goals. Additionally, it is compliant with stringent regulatory requirements for safety and quality across multiple industries. With easy accessibility for maintenance and cleaning, this mixer is engineered to minimize downtime and facilitate straightforward upkeep, ensuring sustained productivity in demanding environments.

Benefits

- Ensures precise mixing quality, enhancing product consistency and reducing waste.

- Increases production efficiency with continuous operation and high throughput.

- Minimizes maintenance time due to easy access and low-maintenance design.

- Supports flexible production needs with customizable configurations.

- Compliant with industry safety standards, ensuring reliable and secure operation.

- Applications

- Dust, Battery masses, Sludge, Metal ores, Food, Chemicals, Polysaccharides, Metallurgy, Friction linings, Detergents, Fire-proof compounds, Glass melts, Raw materials for ceramics, Solvent-based adhesives, Pigments and dyes, Animal feed, Building materials, Non-ferrous metals in powder metallurgy, Fertilisers, Sintering mixes, Welding and soldering agents, Plastics, Carbon and graphite compounds, Ash, Slurry

- End products

- Silica dust, Lithium-ion battery cathodes, Liquid detergent concentrate, Poultry feed pellets, Stainless steel powders, Pectin, Polyurethane adhesives, Flux for soldering, Volcanic ash, Ceramic tiles, Nutritional beverage powders, Concrete slurry, Iron ore pellets, Aluminum powder, Epoxy resins, Graphite electrodes, Bone china porcelain, Abs plastic granules, Borosilicate glass, Urea fertilizer granules, Bio-fertilizer, Ready-mix cement, Titanium dioxide pigment, Automotive brake pads, Intumescent coatings

- Steps before

- Purification, Grinding, Weighing, Feeding, Melting

- Steps after

- Coating, Granulation, Cooling, Drying, Packing

- Input ingredients

- metal ores, sintering mixes, carbon and graphite compounds, raw materials and compounds, non-ferrous metals, glass melts, welding and soldering agents, sanding grain mixes, salts, EPS, master batches, powder coatings, PVAL, polyolefins, natural rubber, solvent-based adhesives, components and additives, plasters, mortars, screed, blast-furnace cement, gypsum, plasterboards, adhesives, fillers, coloured joint mortar, structure protection, insulation systems, plates, stones, finished components, sludge, slurry, dust, ash, contaminated substances, battery masses, friction linings, fertilisers, animal feed, pigments, dyes, fire-proof compounds, detergents, wood substances, ligno substances

- Output ingredients

- high-quality mixes, homogeneous mixes, granulated product, coated particles, fire-proof products, gypsum and plasterboards, coloured joint mortar, processed raw materials, granules, powder injection moulded products, plate-like products, finished components, treated ground material

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Mixing method

- Ploughshare mixer

- Operation type

- Continuous

- Filling level

- 20% - 50%

- Peripheral speed

- Coordinated with geometry

- Retention/mixing times

- Adaptable to specific product

- Throughput

- High

- Liquid addition method

- Pipes or nozzles

- Granulation type

- Makes use of liquids and choppers

- Coating methods

- Liquid addition for particle coating

- Heating/cooling options

- Jacket available

- Cleaning systems

- WIP (Wash in Place)

- Control system

- Modern, user-friendly

- Working mechanism

- Mechanical fluid bed mixing

- Automation level

- PLC

- Batch vs. continuous operation

- Inline Continuous

- Retention/mixing time

- Adjustable

- Chopper inclusion

- Optional

- Liquid addition method

- Pipes or nozzles

- Granulation

- Automatic with liquid addition

- Coating capability

- Capability for reaction coating

- Cooling method

- Liquid nitrogen or carbon dioxide snow

- Energy efficiency

- Optimized for high throughput

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat Sensitivity

- Yes/No

- Viscosity

- 0.5–10, 000 cP

- Foaming Tendency

- High/Medium/Low

- Abrasiveness

- Low/Medium/High

- Particle Size

- 10–1000 µm

- Agglomeration Risk

- Yes/No

- Granulation Requirement

- Required/Optional

- Mixing shaft type

- Horizontal, cylindrical drum

- Footprint

- Compact

- Drum shape

- Horizontal, cylindrical

- Discharge method

- Outlet via large discharge door

- Mixing elements arrangement

- Special arrangement on a mixing shaft

- Peripheral speed

- Coordinated for axial movement

- Material of construction

- Various steels or special materials

- Size adjustment

- Manual and automatic throughput adjustment

- Control panel type

- Modern, user-friendly control system

- Material selection

- Structural steels to stainless steels to special materials

- Liquid addition system

- Pipes for large liquid quantity or nozzles for smaller quantity

- Chopper devices

- Installed to increase turbulence

- Heating/cooling options

- Jacket for heating/cooling of drum, endplates and shaft

- Wear protection

- Application-specific wear protection for components

- Cleaning systems

- WIP (Wash-in-Place)

- Throughput adjustment

- Manual and automatic using installed dams