Pneumatic drying system for industrial slurries

Efficiently transform high-moisture slurries into dry solids in a single pass, optimizing production line integration for seamless moisture control and size reduction across diverse industrial applications.

Reduces Moisture and Dries High-Moisture Slurries

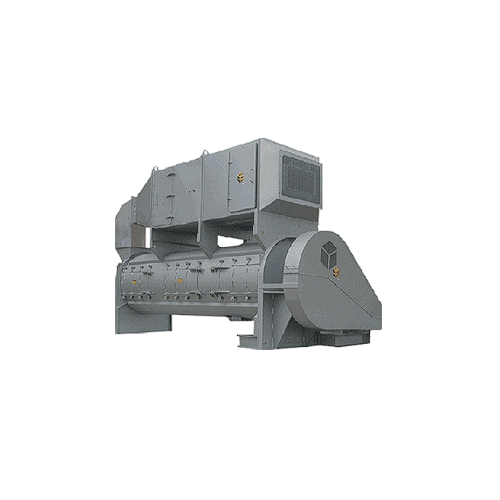

The AST Dryer from Scott Equipment is a high-efficiency pneumatic drying system designed to handle high-moisture slurries with precision and reliability. Engineered for continuous operation, this dryer utilizes a patented agitator design and adjustable air dams to achieve rapid moisture reduction and efficient heat transfer. Ideal for industries ranging from animal nutrition to pharmaceuticals, it processes materials like filter cakes and thixotropic slurries to achieve moisture content as low as 1%. With a throughput capacity tailored to your specifications, the AST Dryer offers customization options including PLC controls for seamless integration into existing production lines. Its energy-efficient operation is driven by a gas-fired burner, optimizing resource use while maintaining product integrity. Constructed with durable materials to ensure longevity, the system is designed for easy maintenance with accessible components and CIP capabilities, ensuring minimal downtime and contamination-free operation.

Benefits

- Minimizes energy costs with high heat transfer efficiency.

- Reduces drying time through rapid moisture evaporation.

- Enhances product quality with controlled moisture removal.

- Supports versatile applications with customizable operation.

- Simplifies maintenance and cleaning with robust, user-friendly design.

- Applications

- Food, Wood flour, Ethanol, Pet food, Poultry litter, Fertilizer, Animal nutrition, Chemical, Industrial, Minerals, Recycling, Pharmaceuticals

- End products

- Dried distillers grains, Kibble dry pet food, Nitrogen-rich fertilizers, Recycled paper pulp, Industrial-grade silica powder, Wood fiberboard, Calcium carbonate additives, Animal feed pellets, Kaolin clay, Dehydrated soup ingredients, Organic compost, Pharmaceutical powder excipients

- Steps before

- Grinding, Mixing, Emulsification, Conveying

- Steps after

- Classification, Cooling, Packing, Bulk Storage

- Input ingredients

- slurries, filter cakes, thixotropies, dilatant slurries, powders, granules, minerals, wood flour, chicken livers, steep water, hatchery waste, bentonite clay, tobacco stems, paper sludge, wallboard waste, fertilizer, manure, kaolin slurry, food dye

- Output ingredients

- dry solids, powders, granules

- Market info

- Scott Equipment is known for its expertise in custom-designed industrial mixing and processing equipment, catering to diverse industries with a strong reputation for quality, innovation, and customer-focused engineered-to-order solutions.

- Moisture Content Input

- Up to 95%

- Moisture Content Output

- Up to 99% dry solids

- Particle Size Reduction

- Effective in Inlet Zone

- Air Velocity

- 11, 000-12, 000 ft/min

- Heat Transfer Coefficient

- High due to velocity and agitation

- Drying Time

- Single Pass

- Temperature Range

- 400°-1200° F

- Burner Type

- Direct/Indirect Gas-Fired

- Automation

- PLC-controlled

- Product Retention Time

- Adjustable

- Air Stream Control

- Negative Pressure System

- Product Feeding System

- Cake Feeder / Mixer Feeder / Pump

- Energy Efficiency

- 10-20% less BTUs per dry ton

- Back-mix Process

- Continuous

- Material Compatibility

- Wet products, filter cakes, slurries

- Working mechanism

- Pneumatic drying system

- Drying process type

- Single pass

- Material type compatibility

- Pulverized powders to granules

- Moisture content reduction

- 5% to 99% dry solids

- Heat transfer method

- Optimum air to solids

- Adjustable features

- Paddles and air dams

- Agitation method

- High velocity and turbulence

- Automation Level

- PLC-controlled

- Material retention adjustment

- Retention Zone Paddles

- Airflow control

- Air dams and paddles

- Energy efficiency

- High heat transfer coefficients

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Control panel type

- PLC-controlled

- Discharge method

- Airflow discharge

- Compact footprint

- Rugged design

- Control panel type

- PLC / HMI

- Discharge method

- Adjustable paddles

- Retention time adjustment

- Yes

- Feeding system types

- Cake Feeder / Mixer Feeder / Pump