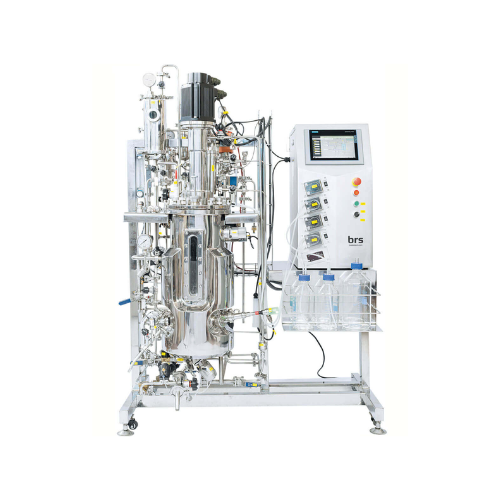

Pilot fermentors for biotech processes

Optimize your pilot-scale production with versatile fermentors and bioreactors designed for precise scaling of microbiological synthesis and small-scale manufacturing, seamlessly bridging the gap between laboratory innovation and large-scale industrial application.

Facilitates Fermentation and Bioprocess Scaling

The BRS-5/7/10SJ, BRS-30SJ, BRS-50SJ, and BRS-80SJ from BRS Biotech are modular pilot fermentors and bioreactors meticulously crafted to scale laboratory results to industrial production environments. These units are indispensable for the biopharmaceutical, agricultural, and veterinary sectors, facilitating the fermentation of enzymes, proteins, and monoclonal antibodies. Their stainless steel construction ensures robust performance and corrosion resistance. Each unit is equipped with precise control systems for temperature, pH, and air flow, enabling fine-tuned process parameters. With compliance to GMP and FDA standards, they integrate smoothly into existing production lines, featuring SIP ports for aseptic processes and advanced SCADA systems for enhanced monitoring. Customization options include varying volumes and specialized sensors, ensuring suitability for specific production needs. Maintenance is streamlined with an open frame construction, ensuring both efficiency and hygiene in daily operations.

Benefits

- Streamlines scale-up with modular design for seamless transition from lab to plant.

- Enhances process control and precision, reducing variability in bioproduction.

- Minimizes operational downtime through easy maintenance and cleaning access.

- Meets stringent GMP and FDA standards, ensuring compliance in pharmaceutical manufacturing.

- Offers customization for specific production needs, improving process optimization and efficiency.

- Applications

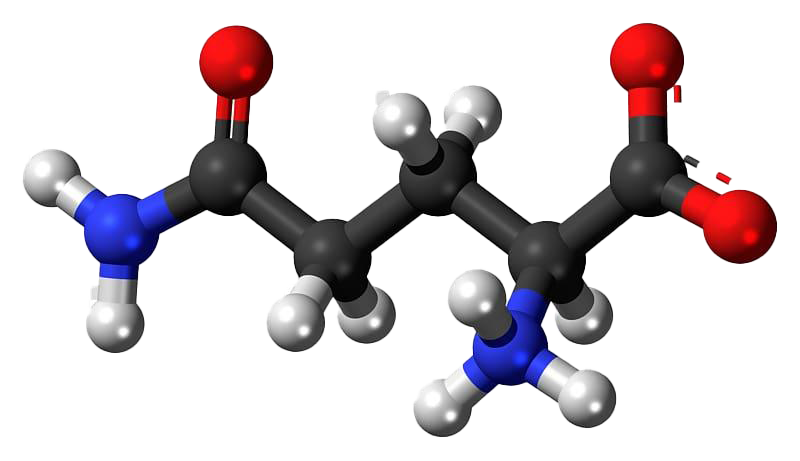

- Amino acids, Proteins, Agricultural chemicals, Plant cells, Veterinary chemicals, Bacteria, Fungi, Animal cells, Biopharmaceuticals, Enzymes, Monoclonal antibodies (mabs), Algae, Microorganisms, Pharmaceuticals

- End products

- Stem cell culture media, Spirulina supplements, Plant tissue culture kits, Probiotic yogurt cultures, Lysine feed additive, Antibiotics, Glyphosate, Rituximab monoclonal antibodies, Lactase enzyme supplements, Human growth hormone, Mushroom-derived supplements, Veterinary vaccines, Recombinant insulin, Yeast for baking

- Steps before

- Medium preparation, Calibration, Inoculation, Raw material input

- Steps after

- Sterilization, Separation, Purification, Freeze drying

- Input ingredients

- enzymes, bacteria, fungi, algae, animal cells, plant cells, agricultural chemicals, veterinary chemicals, proteins, antifoam, acid, alkali, substratum

- Output ingredients

- small-scale pilot production, pharmaceutical production, biotech process outputs, protein production, mAbs production, microbiological synthesis of microorganisms, synthesis of feed amino acids

- Market info

- Total Volume

- 5/7/10/30/50/80 L

- Working Volume

- 4/5/8/21/40/56 L

- Material

- 316 Stainless Steel

- Agitation Type

- Single, double-sealed or magnetic bearing

- Basic Measurement and Control Functions

- Temperature, agitation speed, pH, DO, medium flow, antifoam/level, air flow (manual), pressure (manual)

- Advanced Measurement and Control Functions

- MassFlowControl, automatic air flow meter, air outlet filter heating, optical density sensor, cell suspension concentration sensor, methanol sensor, ethanol sensor, redox sensor, exhaust analysis

- SIP Ports

- For medium inlet system (acid, antifoam, alkali, substratum)

- Automation System

- SCADA advance system

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- CIP / SIP

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Corrosive resistance (e.g. acids)

- 316 Stainless Steel

- Biological compatibility

- Yes

- Cleanability

- SIP (Sterilize-In-Place)

- Abrasion resistance

- High

- Pilot Production Applications

- Agricultural, veterinary chemicals, pharmaceuticals, proteins, mAbs

- Biotech Process Types

- Enzymes, bacteria, fungi, algae, cells

- Small-Scale Production

- Yes

- Volume

- 5 to 80 L

- Material

- 316 Stainless Steel

- Agitation

- Single, double-sealed or magnetic bearing

- Construction

- Platform-mounted, open frame modular

- Discharge method

- Central connections for steam, water, and air

- Construction type

- Open frame modular

- Control cabinet configuration

- Separate cabinet

- Agitation type

- Single, double-sealed or magnetic bearing

- Measurement and control circuit accessibility

- Individual module access

- Remote control system

- SCADA advance

- Customization setup

- Custom setup available via questionnaire