DAF wastewater treatment

The food and beverage industry requires the total removal of suspended solids (TSS), biochemical oxygen demand (BOD5), and oils and greases (O&G). Therefore, they need an efficient solution, highly resilient to process alterations during wastewater treatment with minimal operator intervention.

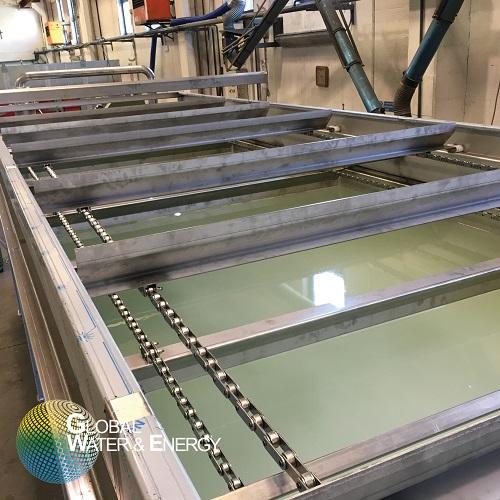

An Efficient Direct Air Flotation Treatment Method

The Global Water & Energy’s SUPERFLOT™ system uses the dissolved air flotation method, which forces floating contaminants to the surface of wastewater, using a curtain of fine air bubbles injected under negative pressure. The air bubbles cling to the suspended particles, which float to the surface. When the atmospheric pressure returns, these rise to the surface, carrying solids, fat, oil, and grease. These are then scraped off and disposed of. A surface skimmer then removes them into an internal hopper for further handling. There are many applications suited to this process. These include livestock processing, laundries and textiles, pulp and paper manufacture, plastics recycling, and food production, to mention a few. The SUPERFLOT system can also operate in tertiary mode with combined coagulant/flocculant dosing. Wastewater cleaned this way may be discharged into surface water subject to local regulations.

Benefits

- Removes solids, fats, oils, and greases from wastewater

- Suitable for separating sludge following aerobic treatments

- Zero-chemical low energy system that is environmentally friendly

- Smaller footprint in comparison with gravity clarification

- Sludge disposal costs are reduced due to a higher solids concentration in the separated sludge