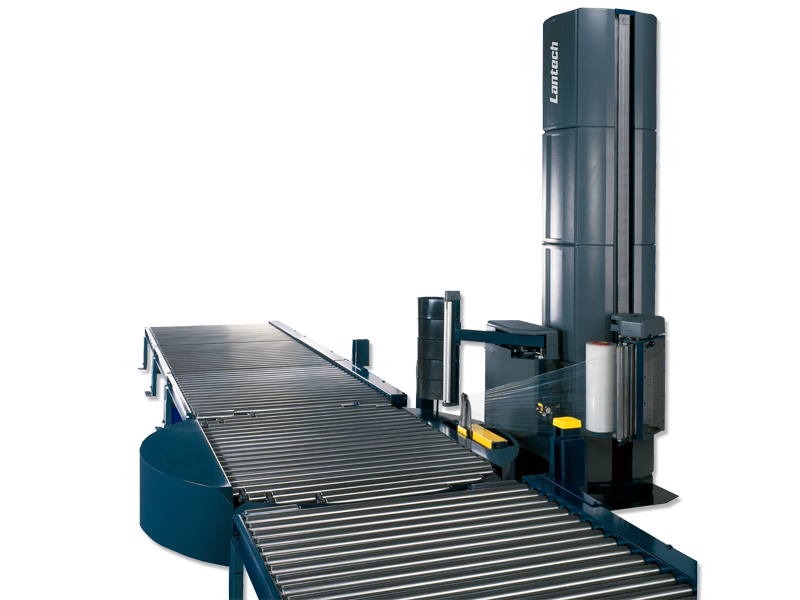

Automatic turn-table stretch wrapper

These stretch wrappers are some of the most versatile, automatic turn-table stretch wrappers in the industry as they can wrap diverse loads and reach production speeds up to 70 loads per hour.

Carefully controlled automatic stretch wrapping on a turn-table

The Lantech QL Automatics wrap up to 70 loads per hour with more force without twisting, crushing or breaking the film because it has fast and easy film changes.

Lantech is committed to observing and understanding work first hand, inside customer plants. This has resulted in what they call LeanWrap™ Technology, which includes a patented Metered Film Delivery™ system, the Guardian System™ and the Pallet-Grip® system.

The patented Metered Film Delivery™ system ensures that film delivery precisely matches your load containment force specifications, your load size and shapes requirements and your speed requirements.

The Guardian System™ manages your stretch wrapping process. This smart system guards against shipping unsafe loads. It guards against machine breakdowns with real time maintenance information. You can view and share detailed production charts.

The patented Pallet-Grip® system prevents load shifting off pallet: It helps you to lock your load to the pallet with a rolled cable of film. The rolled cable is driven down automatically to position just below upper deck of pallet.

Benefits

- No twisting, crushing or breaking the film

- It requires less maintenance and less film build up

- Jaw clamp drops out of the way early in the wrap cycle

- Interlock access gate shuts the machine down if the gate is open