Fluid bed granulator for food and chemical industries

Ensure consistent particle size and moisture control in your production line with an adaptable fluid bed granulation system, capable of transitioning seamlessly between granulation, drying, and coating processes for enhanced product quality and efficiency.

Processes Granulation, Coating, and Encapsulation

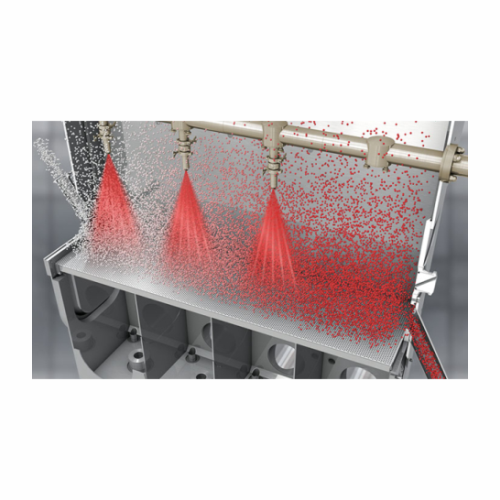

The GFG Series from Glatt is designed to optimize your granulation, coating, and encapsulation processes with maximum efficiency. Utilizing continuous fluid bed technology, these systems support both food and pharmaceutical applications, ensuring precise control over particle agglomeration, drying, and cooling. Capable of processing various end-products, including L-lysine granules and aspartame crystals, this equipment ensures consistent quality and throughput. With flexible modular operations, it integrates seamlessly into production lines, providing high-speed processing and enhanced energy efficiency. Constructed with durable materials to handle a wide range of products, Glatt’s systems are fitted with wash-in-place technology for efficient cleaning, meeting stringent industry standards. Customizable configurations and comprehensive engineering support ensure that the equipment adapts to specific production needs effortlessly.

Benefits

- Enhances production flexibility with adaptable process zones for diverse product requirements.

- Improves energy efficiency, reducing operating costs through optimized process gas utilization.

- Accelerates installation and start-up with pre-assembled modular components.

- Ensures safety and hygiene in sensitive environments with ATEX-compliant and wash-in-place technology.

- Facilitates various product changeovers efficiently, minimizing downtime and ensuring consistent quality.

- Applications

- Food, Feed, Fine chemicals, Phosphonates, Additives, Sweeteners, Pharmaceutical

- End products

- L-lysine granules, Aspartame crystals, Phosphonate detergents, Fish feed pellets, Paracetamol tablets, Vitamin premixes, Corn syrup solids

- Steps before

- Preparation of Raw Materials, Grinding, Emulsification

- Steps after

- Drying, Cooling, Packing, Coating

- Input ingredients

- powders, liquids, solid feedstock

- Output ingredients

- granulated products, coated particles, agglomerates, dried materials, cooled products, phosphonates, sweeteners, additives

- Market info

- Glatt is known for its expertise in process technology and equipment for powder processing and advanced particle systems in the pharmaceutical, food, and chemical industries, recognized for innovative solutions in granulation, drying, and coating processes.

- Capacity

- Variable, depending on zone configuration and settings

- Automation

- PLC-controlled

- Airflow control

- Adjustable per zone

- Process flexibility

- Multiple process steps in a single apparatus

- Operation mode

- Continuous and batch

- Cleaning method

- WIP (Wash-in-Place)

- Design options

- ATEX-compliant, modular

- Energy efficiency

- Energy-optimized, reduced air conditioning needs

- Drying integration

- Integrated within process chamber

- Cooling integration

- Integrated within process chamber

- Working Mechanism

- Fluid bed technology

- Process Integration

- Granulation, drying, cooling

- Batch vs. Continuous Operation

- Continuous

- CIP Principles

- WIP (Wash-in-Place)

- Automation Level

- PLC / SCADA

- Process Zone Flexibility

- Multiple zones

- Air Flow Control

- Variable

- Process Gas Utilization

- Integrated

- Material Movement

- Plug flow

- Changeover Time

- Flexible

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design for limited spaces

- Plant design shape

- Elongated rectangular or round modular designs

- Process chamber division

- Multi-zone capability

- Feed/discharge method

- Continuous operation, plug flow

- Filter placement

- Internal or external options

- Nozzle arrangement

- Flexible and rearrangeable

- Customization level

- Highly adaptable per process requirements

- WIP/CIP capability

- Integrated cleaning options

- Control panel type

- GlattView Varia/Varia+ process control system

- Modular design

- GF ModFlex concept

- Compact footprint

- Modular system solutions with space-saving filters

- Installation type

- Pre-assembled modules

- Filter arrangement

- Space-saving, high efficiency

- Nozzle arrangement adaptability

- Changeable after commissioning

- Hygienic design

- WIP (Wash-in-Place) technology

- Containment

- ATEX-compliant design