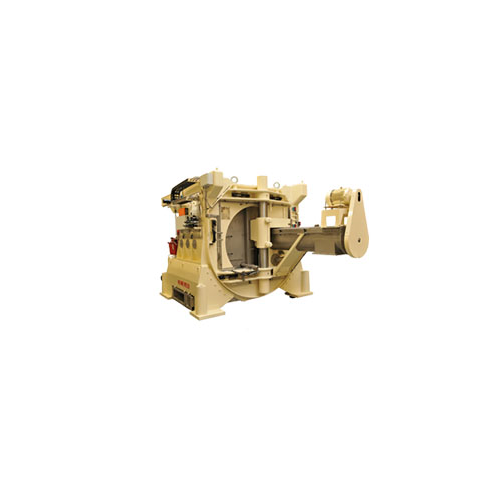

Industrial centrifuge for fine solid dewatering

Achieve precise dewatering of fine crystalline and granular solids, optimizing your production line’s efficiency with reliable, high-capacity processing.

Dewaters and Separates Granular and Crystalline Solids

The REINEVELD HVC series from Dedert Corporation includes rugged basket centrifuges, tailored for high-speed dewatering and separation of granular and crystalline solids. Known for its robust construction, this centrifuge efficiently processes up to 230 metric tons of dry product daily. It is widely utilized in industries such as starch, food, beverage, and pharmaceuticals for applications like processing various starches and plant-based proteins.

Equipped with a high-capacity basket, the centrifuge maintains continuous operation, ideal for large-scale production environments. It features PLC control with remote monitoring and diagnostic capabilities, ensuring seamless integration into existing production lines while providing enhanced operational oversight. The design incorporates energy-efficient motor technology, reducing energy consumption by 15%, and is available in stainless steel to resist corrosion in demanding chemical applications.

Maintenance is streamlined with accessible designs and comprehensive support services, including part replacements and on-site technician deployment. Additionally, Dedert offers customization options for specific rotor speeds and chamber sizes to suit unique processing needs. This centrifuge complies with industry standards, offering reliable performance and longevity.

Benefits

- Maximizes processing capacity with continuous high-speed operation, enhancing overall production efficiency.

- Reduces energy costs by 15% through advanced motor optimization, providing sustainable operation.

- Ensures long-term reliability with rugged construction, minimizing maintenance interventions.

- Integrates seamlessly into existing systems with PLC-controlled operation, reducing labor requirements.

- Supports diverse industry applications with customizable configurations and corrosion-resistant materials.

- Applications

- Food ingredients, Chemical, Plant-based protein, Starch, Biofuel, Pharmaceutical

- End products

- Corn starch, Wheat starch, Pea protein isolate, High-protein ddgs, Potato starch, Wheat gluten, Tapioca starch

- Steps before

- Purification, Separation, Grinding, Emulsification

- Steps after

- Dewatering, Packing, Drying, Milling

- Input ingredients

- corn starch, wheat starch, tapioca starch, potato starch, modified starch suspensions, unmodified starch suspensions, fine crystalline solids, granular solids, chemical products, pharmaceutical ingredients

- Output ingredients

- dewatered starch, dewatered fine crystalline solids, dewatered granular solids, dry product

- Market info

- Dedert is known for its expertise in designing and supplying advanced drying and evaporation technologies, serving the chemical, food, and other processing industries with innovative and efficient engineered-to-order solutions.

- Capacity (metric tons/day)

- 80 MT / Day

- Capacity (metric tons/day)

- 120 MT / Day

- Capacity (metric tons/day)

- 230 MT / Day

- Basket Diameter

- 1400mm / 55"

- Basket Diameter

- 1725mm / 68"

- Basket Diameter

- 2100mm / 83"

- Particle size range

- 3 to 100 micron

- Working mechanism

- Centrifugal

- Particle size range

- 3 to 100 micron

- Batch vs. continuous operation

- Batch

- Maintenance strategy

- On-site maintenance and repair services

- Capacity

- 80–230 metric tons/day

- Application range

- Food, beverage, starch, chemical, pharmaceutical industries

- Automation level

- Custom design services

- Abrasion resistance

- High

- Biological compatibility

- Suitable for food and pharmaceutical applications

- Cleanability

- CIP compatible

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- 3-100 micron

- Material Types

- Fine crystalline or granular solids

- Industries

- Starch, Food, Beverage, Chemical, Pharmaceutical

- Basket Diameter

- 1400mm / 55", 1725mm / 68", 2100mm / 83"

- Capacity

- 80 MT / Day, 120 MT / Day, 230 MT / Day

- Integration possibilities

- On-site commissioning

- Capacity customization

- 80–230 MT/day

- Technological updates

- Latest technologies available

- Custom design services

- Available