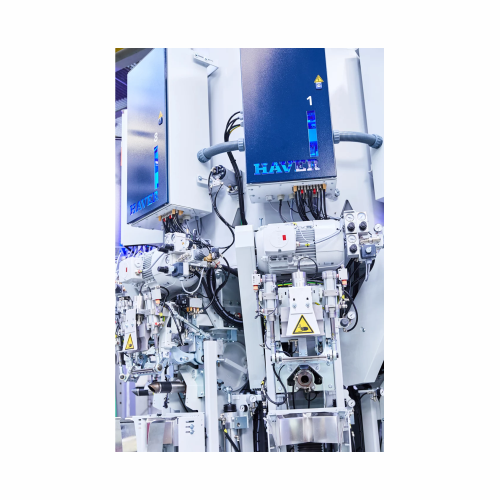

Rotating packaging system for bulk materials

Optimize your bulk material packaging with high-speed, precise rotary packers, ensuring seamless integration and enhanced efficiency in your production line.

Packages and Seals Cement and Chemical Powders

The ROTO-PACKER® series from Haver & Boecker stands out as an efficient solution for packaging and sealing cement and chemical powders. Engineered for high-speed and continuous operations, this equipment supports up to 6,000 bags per hour with diverse applications ranging from cement and mortar mix to gypsum and chemical powders. Available in both RV and RS series, the ROTO-PACKER® can handle valve and tubular film bags, integrating seamlessly into existing production lines. It employs precise weighing electronics with PLC controls for automated processing, remote monitoring, and diagnostics capabilities. The ultrasonic sealing option enhances packaging integrity, while its modular design allows customization in filling technologies—turbine-driven for fine powders and air-driven for varied granulometry. Constructed with high-quality materials like paper, woven PP, or film, it ensures durability and can be adapted with an anti-spillage ROTO-LOCK® system. Perfect for manufacturers in cement, building materials, and chemical industries, the ROTO-PACKER®’s robust construction and flexibility in configuration meet diverse industrial needs while supporting energy efficiency through optimized motor usage. Optional digital equipment further enhances operational efficiency, providing actionable insights into machine performance.

Benefits

- Increases productivity with high-speed packaging capabilities up to 6,000 bags per hour.

- Enhances product protection with weatherproof and tear-resistant packaging options.

- Minimizes spillage and reduces maintenance with the ROTO-LOCK® dosing system.

- Facilitates operational efficiency through integrated remote monitoring and diagnostics.

- Customizable configuration to meet specific production requirements and adapt to various bagging needs.

- Applications

- Building materials, Industrial bulk materials, Chemical products, Cement

- End products

- Mortar mix bags, Drywall compound bags, Cement bags, Grout bags, Pigment powder bags, Chemical powder packaging, Fertilizer bags, Silica bags, Gypsum bags, Adhesive powder bags, Calcium carbonate bags, Alumina powder packaging, Plaster bags, Limestone bags

- Steps before

- Material preparation, Grinding, Mixing, Material handling

- Steps after

- Sealing, Labeling, Palletizing, Storage

- Input ingredients

- cement, building materials, chemical products, fine powders, mixed products

- Output ingredients

- valve bags, tubular film bags, FFS (Form, Fill, Seal) bags, weatherproof bags, recyclable packaging, sealed bags

- Market info

- Haver & Boecker is renowned for its expertise in manufacturing advanced industrial ETO equipment, specializing in material handling, packing, and screening technology for industries like mining, construction, and chemicals, known for innovation and quality.

- Bag type

- Valve / Tubular film (FFS)

- Capacity

- 400–6, 000 bags/hour

- Filling speed

- 7–100 bags/minute

- Filling spouts

- Up to 16

- Automation

- PLC-controlled

- Sealing

- Ultrasonic sealing

- Flexibility

- Configurable for different bag types and sizes

- Expansion Options

- Digital equipment for monitoring, remote control, and diagnostics

- Weighing system

- MEC 4.0 weighing electronics

- Control system

- Siemens TIA portal

- Ventilation

- Intelligent ventilation for optimal filling

- Integration options

- ROTO Adjust, ROTO-LOCK, RADIMAT

- Weather resistance

- ADAMS® technology for weatherproof packaging

- Packaging quality

- Recyclable, safe, and clean packaging

- Automation level

- Optional full digital equipment for monitoring, remote and diagnostics

- Bag Type Compatibility

- Valve, open-mouth, FFS

- Changeover time

- Configurable for various bag types and operations

- Cleaning method

- Safe and clean packaging process

- CIP/SIP

- Available through ultrasonic sealing devices

- Batch vs. continuous operation

- Batch

- Configuration options

- 2-step customization process for user needs

- Capacity Adjustment

- Automated bag saddle height adjustment with ROTO Adjust

- Energy Efficiency

- Intelligent ventilation and illumination systems for optimal operation

- Filling method

- Turbine and air pressure filling systems

- Optional Features

- RADIMAT® for automatic bag placement, QUAT²RO® functionalities

- Sealing Method

- Ultrasonic sealing upgrade available

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Valve bags/open-mouth/FFS bags

- Filling spouts

- Up to 16

- Valve sealing system

- Ultrasonic sealing

- Bagging capacity

- 400 to 6, 000 bags/hour

- Bag type compatibility

- Paper, woven PP, film

- Weatherproof packaging

- ADAMS® film bags

- Compact footprint

- Yes

- Control panel type

- Siemens TIA portal control

- Filling module type

- VT / VL / ST / SL

- Bag type adaptability

- Valve / Tubular film

- Bag saddle height adjustment

- Automatic with ROTO Adjust

- Retrofit options

- SEAL upgrade / Digital monitoring

- Communication Interface

- QUAT²RO® Remote / Scan / Analytics

- Spillage control

- ROTO-LOCK® dosing system

- Bags placement system

- RADIMAT®