Laboratory immersion cooler for precise temperature control

When exact temperature control is crucial for research or production, this immersion cooler solves the challenge by providing adjustable, eco-friendly cooling solutions directly at your workbench, ensuring precise and repeatable conditions without the hazards of traditional refrigerants.

Controls and Stabilizes Temperature for Precision Cooling

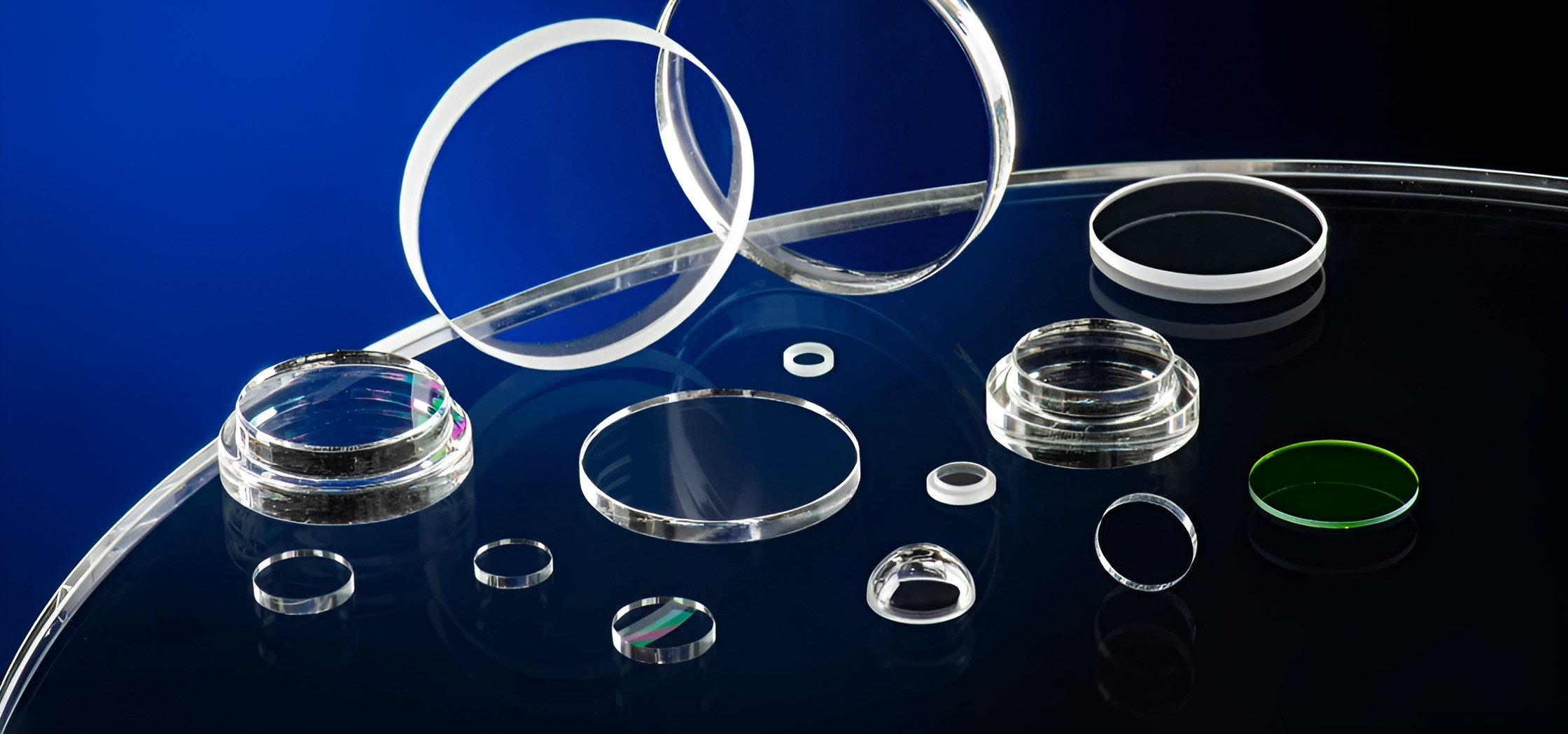

The FTS FlexiCool™ Immersion Cooler from SP Industries provides a versatile and precise cooling solution for demanding applications in pharmaceutical, biotech, and chemical industries. This benchtop cooler uses direct expansion of refrigerant within immersion probes, offering temperatures of -50°C or -100°C as required by your process. Ideal for applications in instrument and equipment cooling, vapor trapping, and coating deposition, it effectively supports the production of semiconductor wafers, optical lenses, and pharmaceutical ingredients.

The FlexiCool™ features eco-friendly, low-global-warming-potential refrigerants that eliminate the costs and hazards related to volatile refrigerants like dry ice or liquid nitrogen. Its RS485 interface allows for robust remote control and data logging capabilities, ensuring precise and reproducible temperature management from anywhere in your facility. The choice of three probe configurations allows seamless integration with various setups, optimizing your bench space. With optional enhancements for PC programming and resistance temperature detector for accurate process control, this immersion cooler meets the stringent demands of modern laboratory and production environments.

Benefits

- Enhances precision with remote monitoring and control capability, ensuring consistent temperature management.

- Minimizes operational costs by using environmentally friendly refrigerants, eliminating the need for expendable volatile coolants.

- Optimizes workspace efficiency with a compact benchtop design.

- Supports diverse applications with customizable probe configurations for specific cooling needs.

- Improves process accuracy through external RTD, ensuring reliable and repeatable results.

- Applications

- Chemical processing, Vapor trapping, Instrument cooling, Equipment cooling, Coating applications

- End products

- Optical lenses, High-purity chemicals, Thin-film photovoltaic cells, Semiconductor wafers, Advanced coatings, Pharmaceutical ingredients, Lab instrumentation components, Parylene-coated medical devices

- Steps before

- Purification, Emulsification, Grinding

- Steps after

- Sterilization, Packing, Parylene Coating, Chemical Vapor Deposition, Instrument or Equipment Cooling

- Input ingredients

- Output ingredients

- Market info

- Temperature Range

- -50 °C to -100 °C

- Design Type

- Compact benchtop

- Control Interface

- RS485 interface

- Refrigeration Method

- Mechanical refrigeration

- Refrigerant Type

- Low GWP refrigerants

- Probe Configuration

- Three standard configurations

- Remote Control Capability

- Yes, via optional communication kit

- Data Logging

- Yes, optional communication kit

- Ramp Soak Program

- 64-segment

- Temperature Control

- External resistance temperature detector (RTD)

- Temperature Range

- -50°C or -100°C

- Remote Control Capability

- RS485 Interface

- Refrigeration Type

- Mechanical Refrigeration

- Probe Configuration

- Three Standard Configurations

- Eco-Friendly Refrigeration

- Low Global Warming Potential Refrigerants

- Automation Level

- 64-segment Ramp Soak Program

- Data Logging Capability

- PC-Controlled via Optional Kit

- Probe configurations

- Three standard options

- Temperature range

- -50°C / -100°C

- Control interface

- RS485

- Immersion probes

- Direct expansion of refrigerant

- Benchtop Design

- Compact