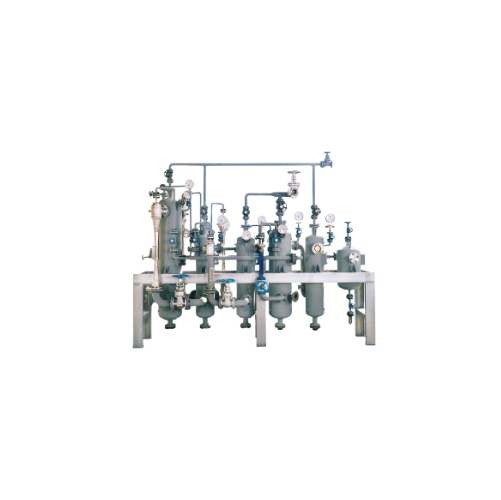

Multi-stage steam jet vacuum pumps for industrial applications

Achieve precise vacuum conditions for evaporation, distillation, and drying processes with multi-stage steam jet vacuum pumps, optimizing efficiency by reducing energy consumption and ensuring purity in end products like pharmaceuticals, textiles, and chemicals.

Creates High-Vacuum Conditions for Efficient Process Control

The multi-stage steam jet vacuum pumps offered by GEA are engineered to solve complex vacuum generation challenges across various industrial sectors. These pumps operate using a series of jet stages to create high-vacuum conditions essential in chemical, pharmaceutical, and food production processes. By utilizing steam as the motive medium, they efficiently reduce suction pressures to as low as 0.01 mbar, making them suitable for applications in distillation, freeze drying, and deodorizing.

With a robust compression capability, these pumps can handle extensive compression ratios, ensuring optimal performance even under demanding conditions. Designed to fit seamlessly into existing production lines, they can be integrated with mechanical vacuum pumps for enhanced vacuum control. Their construction allows for handling a wide range of gases and vapors, including ammonia and caprolactam, and they are vital for producing polyester fibers and refined hydrocarbons.

Available in materials such as stainless steel and special alloys for chemical compatibility, these pumps feature both mixing and surface condenser options depending on process requirements. Their low maintenance, long service life, and flexibility in material selection make them ideal for operations involving corrosive substances. The option for heat jacketing prevents common issues like icing and ensures reliable performance in various settings. Additionally, GEA supports customization and engineering assistance to meet specific process needs, enhancing the adaptability of these vacuum pumps to your production requirements.

Benefits

- Increases process efficiency by achieving extremely low suction pressures.

- Minimizes operational costs with maintenance-free design and long service life.

- Offers flexibility with material options suitable for corrosive environments, enhancing durability.

- Saves energy by utilizing recovered product vapor as motive medium in closed systems.

- Ensures seamless process integration with customizable configurations and engineering support.

- Applications

- Chemicals, Food, Foil, Deodorizing, High melting point substances, Halogen gases, Degassing, Vacuum distillation, Freeze drying, Poly-condensation, Rectifying, Driers, Polyester, Refineries, Textiles, Distillation, Pharmaceuticals

- End products

- Vacuum-packed foods, Textile fibers, Oligomers, Ammonia, Distilled spirits, Halogen-based industrial chemicals, Freeze-dried fruit, Heat-resistant poly-condensation polymers, Deodorized oils, Film sheets, High-purity chemicals, Polyester fibers, Refined hydrocarbons, Caprolactam, Pharmaceuticals with low boiling points, Essential oils

- Steps before

- Evaporation, Distillation, Poly-condensation, Degassing

- Steps after

- Deodorizing, Freeze Drying, Rectifying

- Input ingredients

- steam, process gases, water steam, product vapor, ammonia, chalky water, high melting point constituents, caprolactam, oligomers, low polymers

- Output ingredients

- vacuum, evacuated gases, condensate, compressed gases, distilled products, deodorized gases

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Suction Pressure

- Up to 0.01 mbar

- Suction Capacity

- Up to 2 million m³/h

- Compression Ratio

- 1

- Steam Type

- Water steam, product steam

- Condenser Type

- Mixing or surface condensers

- Materials for Jet Pumps

- Cast iron, steel, stainless steel

- Materials for Condensers

- Steel, rubberized steel, enameled steel, stainless steel, bronze, special alloys

- Heating Method

- Heat jacketing with diphyl, oils, or heat carrier fluid

- Operating Conditions

- Maintenance-free, no moving parts

- Installation

- Flexible, can be quickly and easily put into operation

- Working mechanism

- Jet pump technology

- Integrated steps

- Multi-stage arrangement

- Suction pressure range

- 0.01 - 6 mbar

- Compression ratio

- 1

- Cooling method

- Water-cooled / Air-cooled condensers

- Material options

- Cast iron, stainless steel, porcelain

- Motive medium

- Steam

- Maintenance Level

- Low maintenance

- Closed system design

- Ecological and economic efficiency

- Heating prevention measures

- Heat jacketed ejectors

- No moving parts

- Yes

- Installation flexibility

- Various situations

- Operation initiation

- Quick and easy

- Lifecycle expectation

- Almost unlimited life

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- High Melting Point Handling

- Heat Jacketing Recommended

- Material of Construction for Jet Pumps

- Cast iron, steel, stainless steel

- Material of Construction for Condensers

- Steel, rubberized or enameled steel, stainless steel, bronze, porcelain, graphite, glass

- Material of Construction for Piping

- Plastics, porcelain, glass

- Material of Construction for Jet Pumps

- Cast Iron / Steel / Stainless Steel

- Material of Construction for Condensers

- Steel / Rubberized Steel / Enameled Steel / Stainless Steel / Bronze / Special Alloys

- Material of Construction for Corrosive Applications

- Porcelain / Graphite / Glass

- Heat Jacketing for Ejectors

- Vaporous or Liquid Diphenyl / High Temperature Resistant Oils / Other Heat Carrier Fluids

- Condensation Type

- Mixing Condensers / Surface Condensers

- Operating Fluid

- Water Steam / Product Steam

- Type of Steam Jet Vacuum Pump

- DPM1 / DPO1 / PGV1