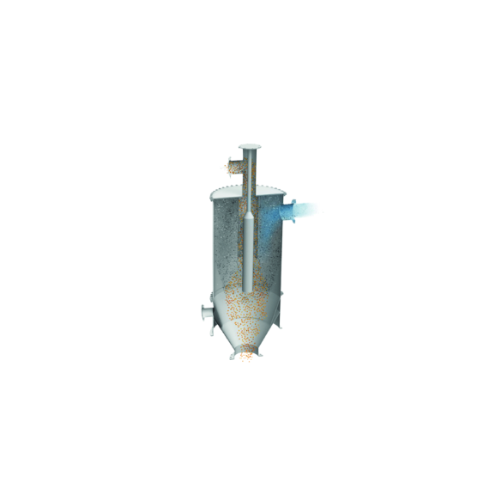

High-efficiency pellet dust separator

Achieve unparalleled separation efficiency in your polymer production line by removing dust and streamers, ensuring optimal granule purity and enhancing product quality.

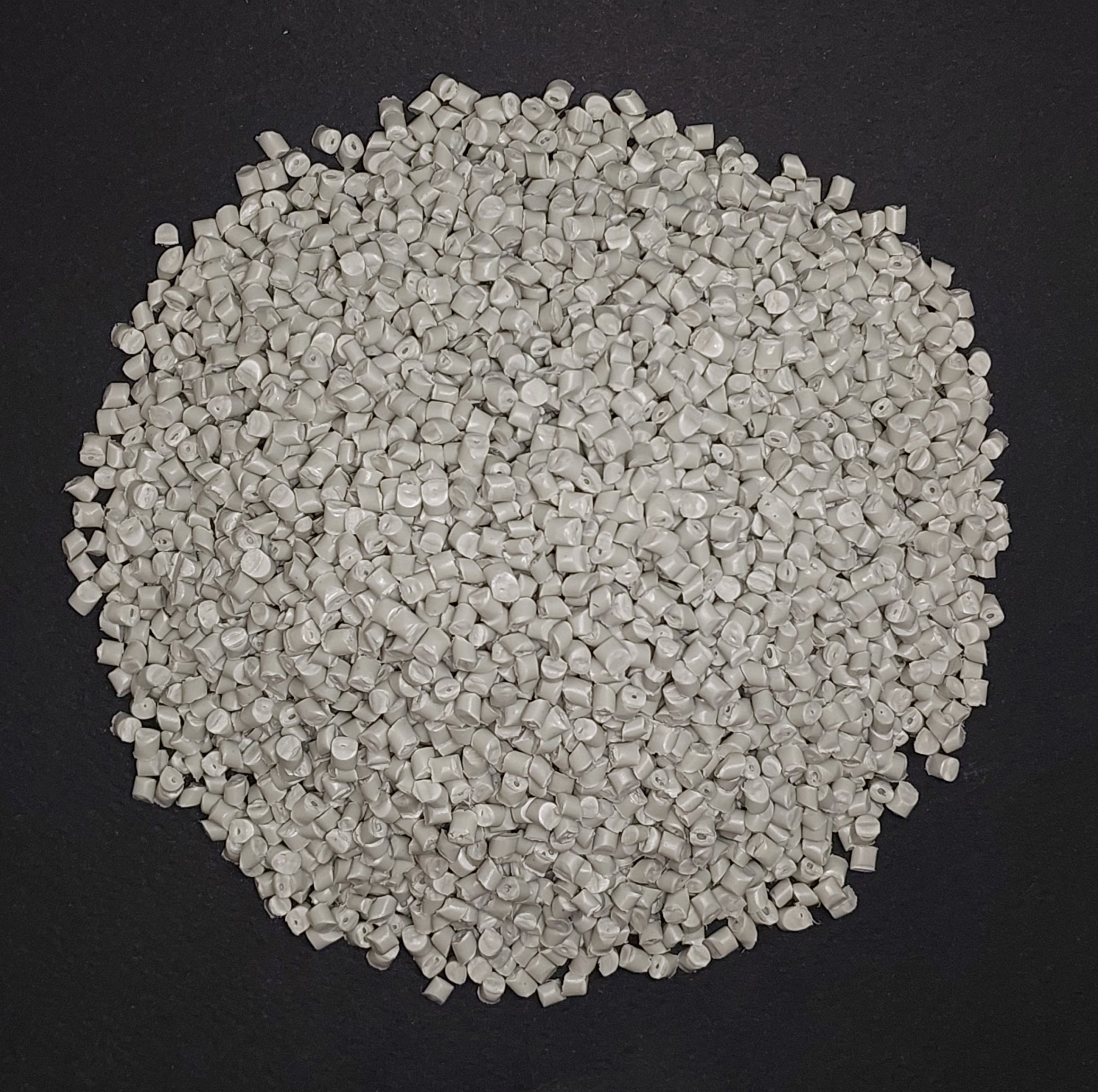

Separates and Cleans Polymer Pellets

The GSE separator ZSD from Zeppelin Systems excels in eliminating fine dust and long streamers from polymer pellets, enhancing product purity for polyethylene, polypropylene, and rubber industries. This separator uses a counter-current gas flow to achieve high separation efficiency by accelerating pellets and maintaining consistent output during continuous operation. Capable of handling up to 120 metric tons per hour, it integrates seamlessly into pneumatic conveying systems. Its design minimizes pressure loss and allows direct feeding via dense phase conveying, eliminating the need for transfer hoppers. Constructed for durability, the ZSD requires minimal maintenance due to its non-rotating parts. Customization options are available to suit specific product and throughput requirements, ensuring optimal integration into your existing production line.

Benefits

- Ensures high-purity end products with efficient separation of dust and streamers.

- Increases production capacity by handling up to 120 metric tons per hour.

- Lowers operational costs with maintenance-free design due to absence of moving parts.

- Enhances system efficiency with reduced pressure loss through optimized design.

- Facilitates seamless integration into existing pneumatic conveying systems.

- Applications

- Polymers, Chemical, Tire industry, Plastics, Rubber

- End products

- Polyethylene pellets, Raw tire rubber compounds, Pvc resins, Polypropylene granules, Styrene-butadiene rubber beads, Rubber granules, Epdm rubber pellets

- Steps before

- Pelletizing, Dust Collection, Pellet Transport

- Steps after

- Packing, Quality Check, Distribution

- Input ingredients

- pellets, conveyed material, polymers, dense phase conveyed material

- Output ingredients

- cleaned pellets, cleaned material, separated dust particles, removed long streamers, separated angel hairs

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Separation Efficiency

- Consistent throughout operation

- Capacity

- Up to 120 metric tons per hour

- Pressure Loss

- Reduced thanks to optimized design

- Feeding Method

- Gravimetric feeding and direct feeding with dense phase conveying

- Stream Deflection

- 180° air stream deflection

- High separation efficiency

- Consistent throughout operation

- Automation level

- Integrated into pneumatic conveyor systems

- Batch vs. continuous operation

- Continuous operation

- Separation method

- Counter-current air flow and particle deflection

- Maintenance

- Maintenance-free design

- Customization

- Individual customization

- Particle removal

- Streamers and dust particles

- Loading rate

- Higher than other separator types

- Feeding options

- Gravimetric or direct by dense phase

- Abrasion resistance

- High

- Cleanability

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Biological compatibility

- Not Applicable

- Density,particle size

- 0.5–2.5 g/cm³ / 50–500 µm

- Usage type

- Direct integration into pneumatic systems

- Feed method

- Gravimetric / Dense phase conveying

- Discharge method

- Downstream rotary feeder

- Customization options

- Individual customization to suit product and throughput

- Pressure loss

- Reduced loss due to optimized design

- Individual customization

- Product-specific calibration and throughput optimization

- Control panel type

- PLC-controlled with integration options

- Integration possibilities

- Direct integration into pneumatic conveyor systems