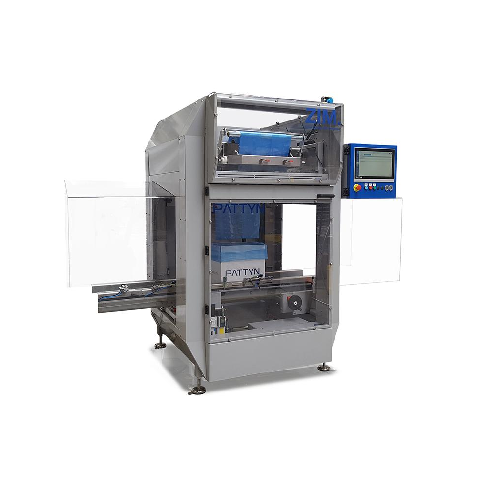

Automatic bag inserter for boxes and crates

Optimize your packaging line with a compact solution that seamlessly inserts polyethylene bags into various container types, ensuring continuous operation with minimized material waste and enhanced hygiene.

Inserts and Opens Bags Automatically

The ZIM-31 Poly Bag Inserter from Pattyn Packaging Lines is an automatic bagging machine designed to enhance efficiency and hygiene for industrial packaging applications. Its unique feature is a patented smart film opening technology combined with a vacuum and air insertion system, ensuring reliable bag opening. The ZIM-31 handles various container types, including cardboard boxes, plastic crates, and trays, making it highly versatile for industries such as food, logistics, and manufacturing. It supports a throughput of up to 14 cases per minute and features a continuous operation capability thanks to an automatic film roll exchange. Equipped with a user-friendly 15” HMI and ergonomic design, this machine guarantees minimal downtime with its quick-loading film system and compact footprint. Additionally, it integrates seamlessly into automated production lines when combined with Pattyn’s case erector, weigh filler, and palletizer, delivering a cohesive packaging solution.

Benefits

- Ensures operational efficiency with automatic film roll exchange, minimizing interruptions.

- Saves packaging costs by using polyethylene bags from a reel.

- Facilitates user operation with an intuitive 15” HMI interface.

- Adapts to varying container sizes and types, accommodating diverse packaging needs.

- Protects product integrity with failsafe bag opening and hygienic insertion methods.

- Applications

- Trays, Cardboard boxes, Plastic crates

- End products

- Pharmaceutical supplies, Detergents, Bulk nuts, Fresh produce, Industrial components, Confectionery items, Dry goods, Frozen poultry, Bakery products, Electronics, Dairy products

- Steps before

- Case Erecting, Weighing and Filling

- Steps after

- Bag Closing, Case Closing, Palletizing

- Input ingredients

- polyethylene film, boxes, crates, trays

- Output ingredients

- PE bags, bagged boxes, bagged crates, bagged trays

- Market info

- Pattyn is known for its expertise in designing and manufacturing industrial packaging solutions, specializing in ETO equipment for bulk packaging automation, with a strong reputation for innovation, quality, and customer-focused service in the industry.

- Automation

- Fully automated

- Speed

- Up to 14 cases/min

- Footprint

- 1.7 x 1.3 m

- Film type

- Polyethylene film

- Bag type

- Made-to-measure / Pre-made bags

- Control interface

- 15” HMI

- Box size range

- Min. L.300 x W.200 // D.250, Max. L.610 x W.410 // D.650

- HMI size

- 15 inches

- Output

- 8 c/min standard, 14 c/min with fast machine option

- Film roll weight

- 12 kg

- Technology

- Patented smart film opening technology

- Gripper module

- Strong gripper, spoon module

- Warning indicator

- Multicolour warning light

- Automation level

- Automatic

- Bag insertion speed

- Up to 14 cases/minute

- Film roll exchange

- Automatic

- HMI Control

- 15” HMI

- Footprint

- 1.7 x 1.3 m

- Failsafe bag opening

- Yes, with strong gripper, spoon module

- Smart film opening technology

- Patented with vacuum, air insertion

- Loading method

- Quick and ergonomic film roll loading

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Cardboard box / Plastic crate / Tray

- Machine footprint

- 1.7 x 1.3 m

- Control panel type

- 15” HMI

- Compact footprint

- Super compact

- Container dimensions

- Min L.300 x W.200 x D.250 mm

- Max L.610 x W.410 x D.650 mm

- Compact footprint

- 1.7 x 1.3m

- Control panel type

- 15” HMI

- Integration possibilities

- Infeed conveyor with separator

- Automation level

- Automatic film roll exchange