Ethylene cracking gas cooling system

Quickly reduce gas temperatures in high-capacity ethylene plants with a robust cooling solution designed to optimize heat recovery and enhance operational efficiency in continuous production environments.

Cools and Stabilizes Cracked Gas Streams

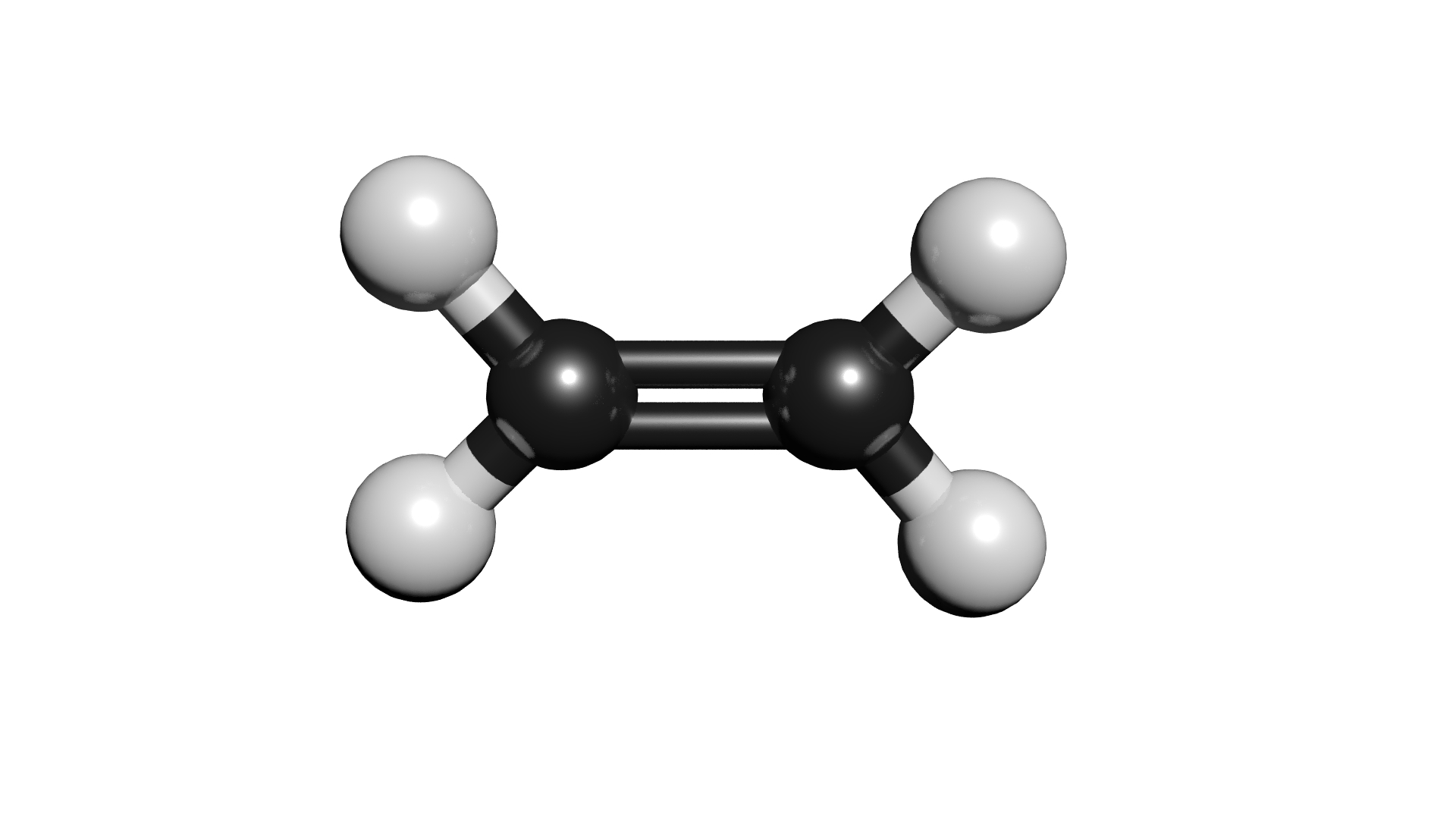

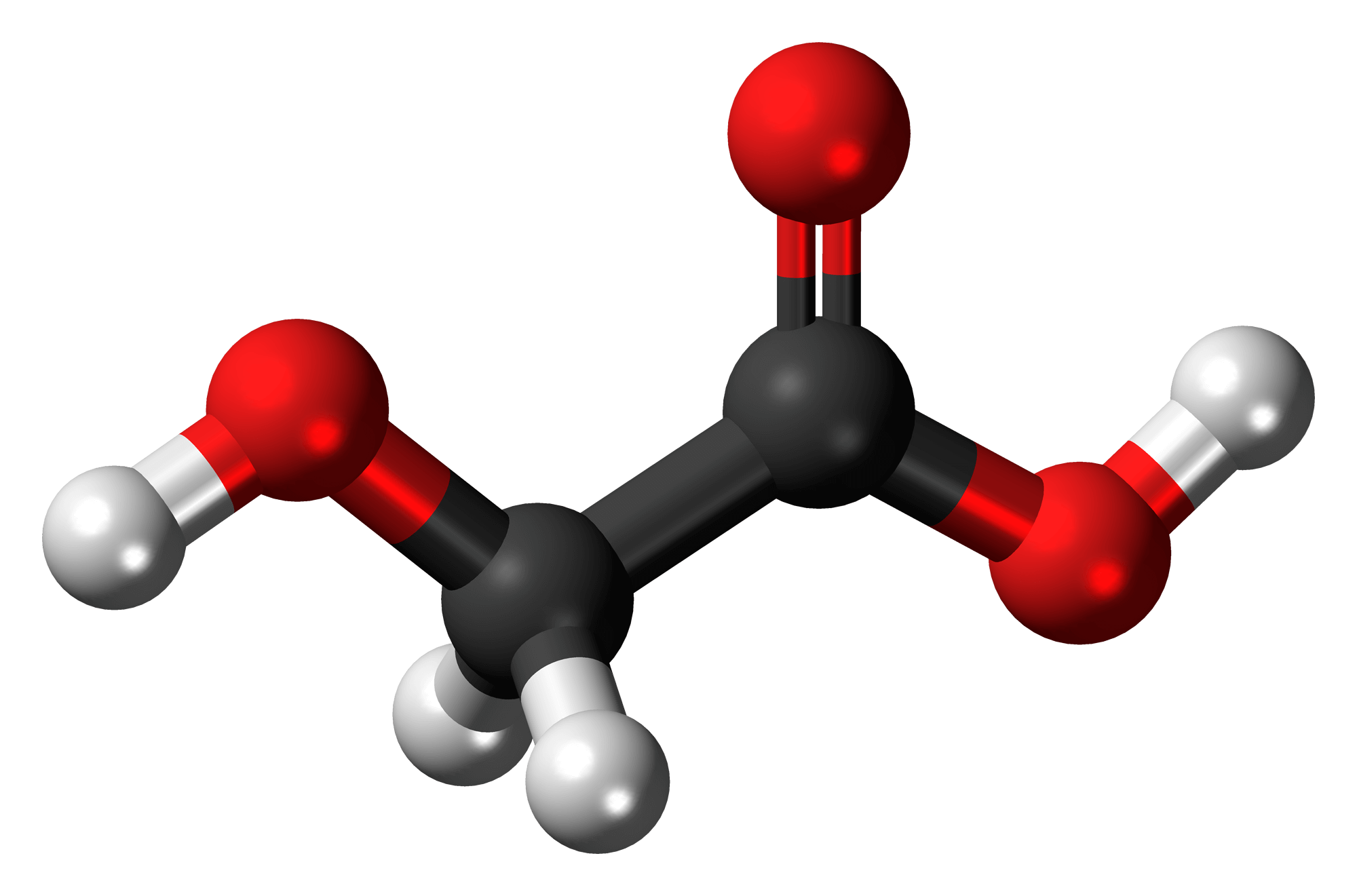

The BORSIG “Tunnelflow” Transfer Line Exchanger efficiently cools cracked gas in petrochemical processes, particularly in ethylene production plants. Designed with a robust shell and tube configuration, it ensures smooth integration into continuous operations, handling diverse mass flows and heat duties with precision. Featuring a unique thin reinforced tube sheet design, it provides exceptional cooling performance with minimized thermal stress, reducing the need for frequent maintenance. The system allows swift blowdown via a quick-open valve and includes an optional erosion-protection shield for enhanced durability. Manufactured using 0.5 Mo material, it requires no post weld heat treatment, optimizing operational efficiency. The exchanger’s high water velocity prevents deposit accumulation, ensuring reliable long-term performance. Proven in applications ranging from ethylene glycol and polyethylene production to urea and ammonium nitrate synthesis, this equipment is a critical component for petrochemical companies needing efficient waste heat recovery solutions.

Benefits

- Enhances ethylene production efficiency by rapidly cooling cracked gas streams.

- Minimizes maintenance with robust design and optional erosion protection.

- Operates continuously without deposit accumulation, ensuring consistent performance.

- Optimizes operational costs with energy-efficient material requiring no post-weld treatment.

- Supports versatile integration for various mass flows and heat duties in petrochemical processes.

- Applications

- Hydrogen, Methanol, Ammonia, Ethylene, Synthesis gas

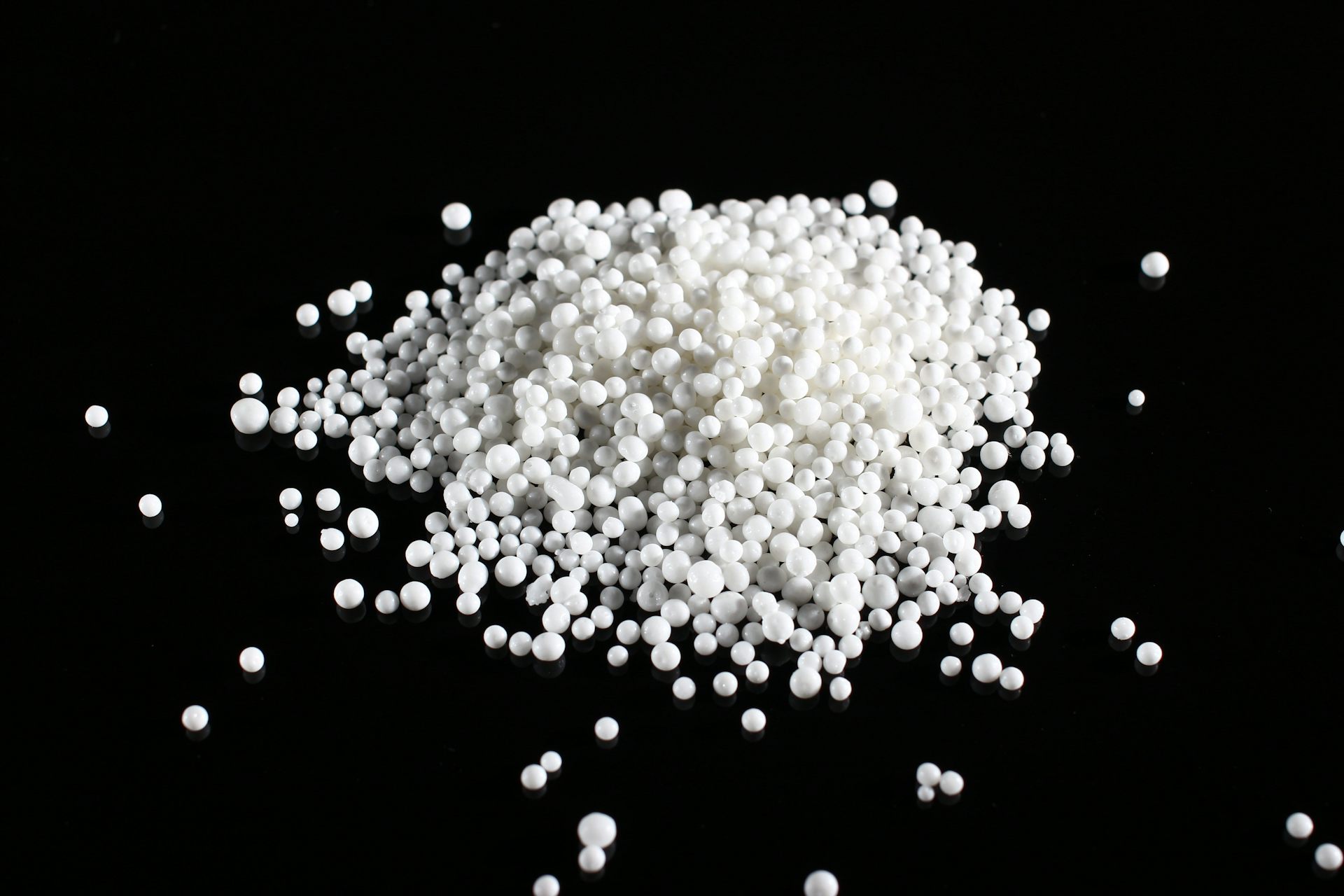

- End products

- Polyethylene, Formaldehyde, Ammonium nitrate, Ethylene glycol, Urea

- Steps before

- Cracking, Gas purification

- Steps after

- Steam integration, Heat recovery

- Input ingredients

- cracked gas

- Output ingredients

- cooled gas, steam

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Cooling Medium

- Steam

- Arrangement

- Vertical or Horizontal

- Material

- 0.5 Mo

- Heat Exchanger Type

- Shell, Tube Design

- Tube Bundle Design

- Large Water Volume

- Tube Sheet Type

- Thin Reinforced

- Gas Distribution

- Uniform due to Trumped Shape Design

- Optional Features

- Erosion-Protection Shield

- Maintenance

- Easy Maintenance

- Cooling method

- Tube bundle heat exchanger with steam drum

- Configuration

- Vertical or horizontal arrangement

- Flow characteristics

- Uniform gas distribution via trumped shape design

- Pressure limits

- No operating pressure limit on water/ steam side

- Compactness

- Large water volume in shell design

- Material characteristic

- 0.5 Mo material, no post weld heat treatment

- Maintenance

- Easy maintenance with quick open valve for blowdown

- Protection features

- Erosion-protection shield available

- Tube sheet design

- Thin reinforced tube sheet at gas inlet

- Corrosive resistance

- Suitable for handling corrosive gases

- Biological compatibility

- Not applicable

- Cleanability

- High cleanability with optional blowdown

- Machine footprint

- N/A

- Configuration

- Vertical or Horizontal arrangement

- Tube bundle size

- Large water volume, robust shell

- Riser/Downcomer Count

- One or Two per exchanger

- Inlet channel design

- Trumped shape for uniform gas distribution

- Erosion protection

- Optional Erosion-protection shield

- Blowdown capability

- Via quick open valve

- Customization for mass flow and heat duty

- Tailored for specific plant requirements

- Vertical or Horizontal Arrangement

- Customizable arrangement

- Erosion-protection shield

- Optional

- Possibility of Blowdown

- Quick open valve