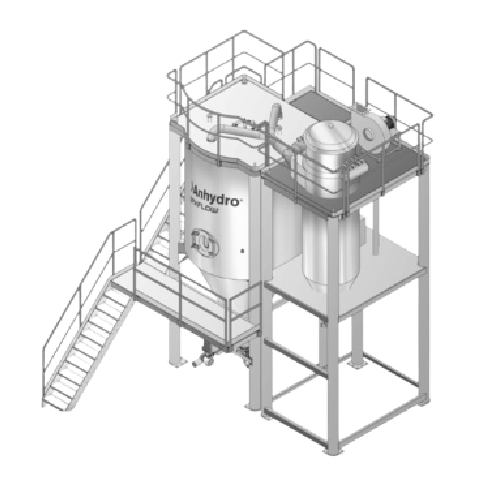

Small scale spray dryer for r&d and production

For precise moisture removal in small batches, this flexible spray drying solution enables researchers and producers to efficiently test and develop new formulations, ensuring high-quality powdered products from liquids.

Processes Liquid into Powder via Spray Drying

The Anhydro MasterSpray from SPX FLOW is a versatile modular spray dryer designed for small-scale and R&D facilities needing precise control over drying processes. It transforms liquids into powders efficiently, supporting industries such as food, dairy, chemicals, and pharmaceuticals in producing end-products like powdered milk formulas, encapsulated vitamins, and test batches. Based on a unique modular design, the system can be customized with various optional components to match specific operational needs. With gas rate sizes of 1,250 and 2,500, the MasterSpray offers adaptable drying capacities ideal for small-batch, high-quality output. It features smooth integration into existing production lines with ease, and its design ensures energy-efficient operation by optimizing airflow and drying parameters. Constructed to support rigorous R&D activities, the Anhydro MasterSpray is a reliable choice for institutions seeking quality and innovation in spray-drying technology.

Benefits

- Optimizes small-batch production with a customizable modular design.

- Enhances R&D precision with adjustable drying parameters.

- Integrates seamlessly into existing workflows, reducing setup time.

- Improves energy efficiency by optimizing airflow, lowering operational costs.

- Facilitates versatile application across multiple industries, boosting innovation potential.

- Applications

- Food, Chemicals, Academic research, Small batch products, R, D products, Dairy, Pharmaceuticals

- End products

- Vaccine adjuvant powders, Experimental cosmetic powders, Nutritional supplements, Academic chemical samples, Powdered milk formulas, Instant soup powders, Protein supplements, Encapsulated vitamins, Test batches of new food products, Freeze-dried bacteria cultures

- Steps before

- Purification, Homogenization, Mixing, Blending

- Steps after

- Packing, Coating

- Input ingredients

- food ingredients, dairy products, chemical substances, pharmaceutical compounds

- Output ingredients

- dried food products, dairy powders, chemical powders, pharmaceutical powders

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Gas Rate Size

- 1, 250 and 2, 500

- Application

- Small scale production, R, D, universities, public institutions

- Modularity

- Customizable with modular design

- Batch vs. continuous operation

- Batch

- Automation level

- Customizable / Modular

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Scale of production

- Small scale

- Industries served

- Food, Dairy, Chemical, Pharmaceutical

- Compact footprint

- Modular design

- Customization Options

- Modular concept

- Control panel type

- PLC / HMI / SCADA

- Gas rate size

- 1, 250 / 2, 500

- Modular design

- Basic plant with optional items

- Integration possibilities

- Customizable to specific needs