Centrifugal separator for chemicals and minerals

Achieve precise separation of liquids and slurries with this high-speed centrifugal technology, ensuring safety in processing hazardous materials while enhancing product purity and operational efficiency.

Separates Liquids and Slurries in Continuous Operations

The GEA Centrifugal Separator is engineered for demanding environments in the chemical, petrochemical, and mineral industries. It efficiently separates liquids and slurries using liquid centripetal pumps for continuous discharge under pressure, ensuring safety in handling concentrated acids and explosive substances. Suitable for products like sulfuric acid, calcium carbonate, and plant-based foods, it operates at high speeds with full automation, seamlessly integrating into existing production lines. This equipment handles a substantial throughput, offering significant energy savings due to optimized motor control. Constructed with corrosion-resistant materials, it meets international safety and quality standards. Additionally, the GEA separator supports easy cleaning and maintenance with options for engineering customization to meet specific operational needs.

Benefits

- Enhances product purity and quality with precise separation capabilities.

- Minimizes safety risks by maintaining containment of hazardous substances.

- Reduces operational costs with energy-efficient motor systems.

- Ensures seamless integration and process automation, reducing manual intervention.

- Versatile across multiple industries, accommodating a wide range of applications.

- Applications

- Chemicals, Alternative proteins, Egg alternatives, Dairy alternatives, Meat alternatives, Petrochemicals, Seafood alternatives, Minerals, Mineral oil

- End products

- Plant-based chicken, Lubricating oil, Almond milk, Ethylene, Egg replacer powder, Sulfuric acid, Vegan fish fillets, Calcium carbonate

- Steps before

- Purification, Emulsification, Grinding

- Steps after

- Sterilization, Packing, Coating

- Input ingredients

- concentrated acids, high pressure substances, inflammable substances, explosive substances, chemicals, minerals

- Output ingredients

- processed chemicals, processed minerals, discharged substances

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Corrosion resistance

- Designed to resist concentrated acids

- Pressure handling

- High-pressure capacity

- Safety features

- Safely discharging under pressure

- Discharge method

- Liquid centripetal pump

- Explosion-proof features

- Inflammable/explosive substance capacity

- Working mechanism

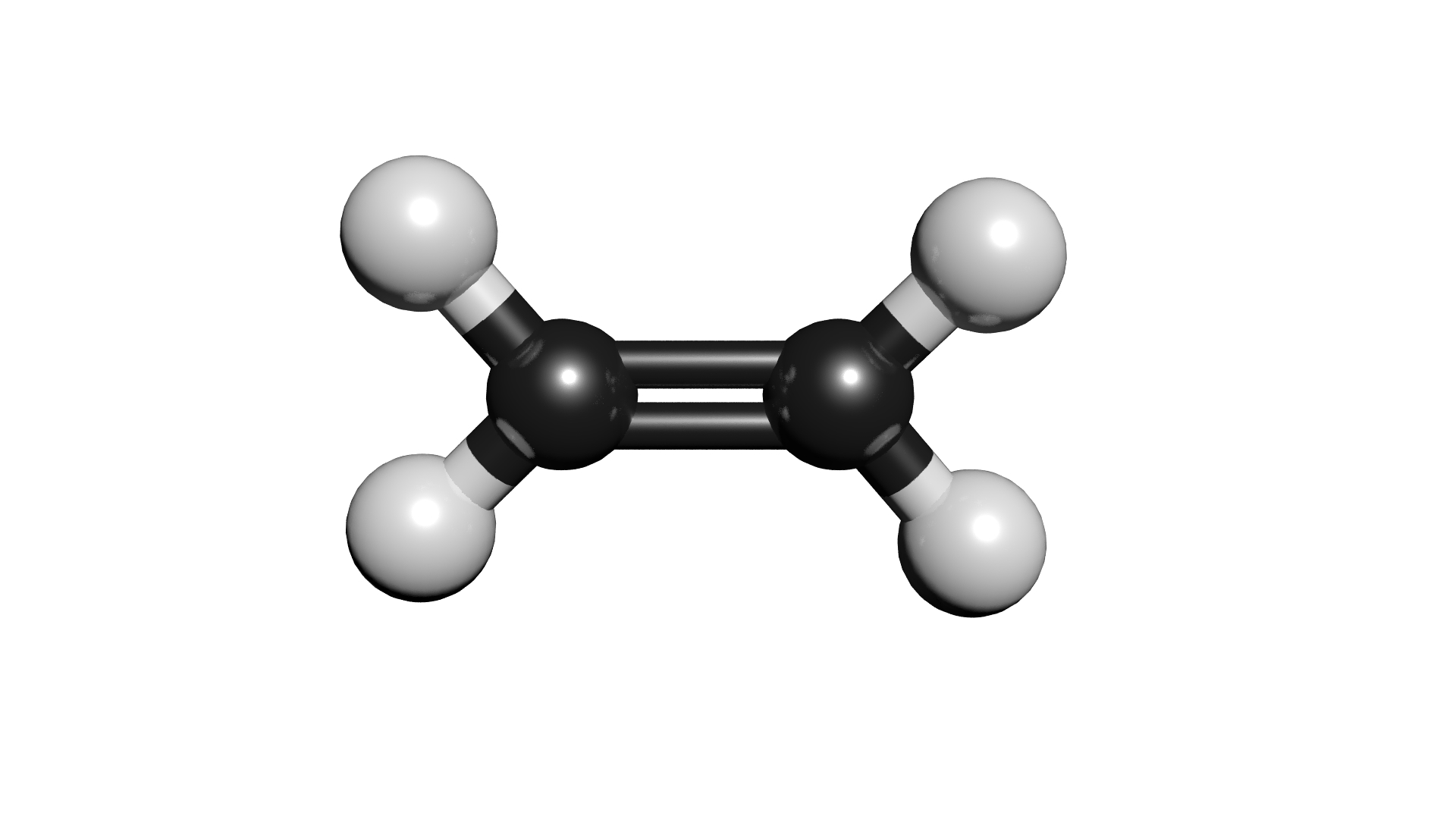

- Centrifugal separation

- Discharge method

- Liquid centripetal pumps

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP

- Safety features

- High-pressure and chemical resistance

- Corrosive stuff handling

- Withstands acids and inflammable substances

- Corrosive resistance (e.g. acids)

- Highly resistant

- Chemical resistance

- Acids and inflammables

- Component material

- Corrosion-resistant

- Discharge method

- Pressure discharge

- Shape

- Bowl shape

- Size

- Customizable

- Control panel type

- Standardized / Tailor-made / PLC-integrated

- Automation level

- Manual / Auto / PLC-controlled

- Integration possibilities

- Seamless with other systems

- Discharge method

- Pressure-based / Safe discharge