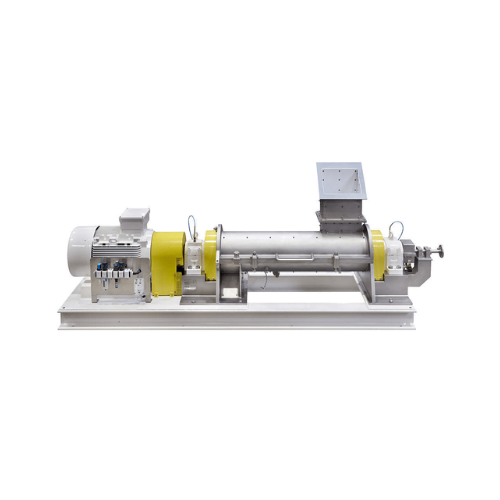

High-speed mixer for continuous high throughputs

Achieve exceptional homogeneity in mixing liquid and pasty components into dry substances with high speed and precision, optimizing throughput efficiency in continuous operations across varied production environments.

Mixes and Disperses Components Efficiently

The CoriMix® from Lödige Maschinenbau is a high-speed, continuous ring layer mixer designed for the homogeneous integration of liquid and pasty components into dry bases. This equipment excels with its high peripheral speed, forming a concentric ring layer within the drum, optimizing mixing through centrifugal force. Its plug-flow mechanism ensures short retention, enhancing mixing efficiency across diverse applications, including building materials and pharmaceuticals, producing end-products like ready-mix concrete and vitamin supplements. Capable of handling various processes such as granulation and agglomeration, the CoriMix® ensures precise control over shear intensity with adaptable mixing tools. Its robust construction offers ATEX conformity and wear-resistant features, ensuring reliability and durability. The mixer supports large-scale liquid addition with minimal contamination risk, thanks to its tangential liquid delivery and non-clogging design. With options for material and temperature control, it meets stringent industrial standards, providing flexible solutions tailored to your production needs.

Benefits

- Enhances product uniformity with high-speed continuous mixing.

- Minimizes operational downtime through efficient plug-flow processing.

- Facilitates large liquid additions without clogging, improving process efficiency.

- Adapts to various mixing intensities, optimizing for different product requirements.

- Ensures operational safety with ATEX-certified design.

- Applications

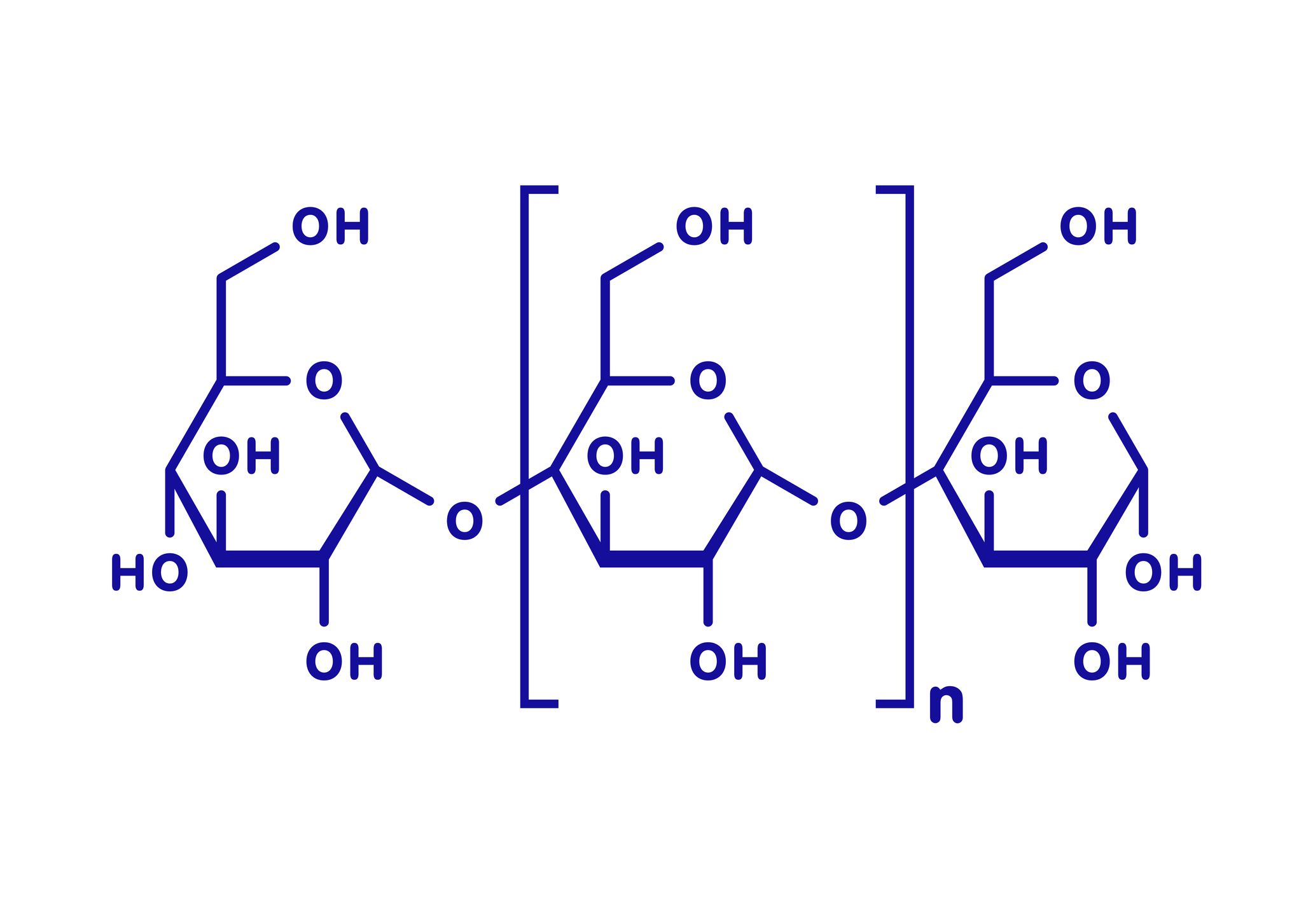

- Food, Polysaccharides, Metallurgy, Building materials, Chemical industry, Environment, Plastics, Pharmaceuticals

- End products

- Polyethylene pellets, Baby formula powder, Compost enrichments, Powdered metal blends, Cellulose-based thickeners, Vitamin supplement tablets, Ready-mix concrete, Polyurethane foams

- Steps before

- Grinding, Drying, Emulsification

- Steps after

- Granulation, Coating, Cooling, Recrystallization, Drying, Packing

- Input ingredients

- liquid components, pasty components, dry substances, binding agents, molten fat

- Output ingredients

- homogeneous mix, granulated product, coated particles, increased bulk density, grain size between 100 µ and 1.5 mm

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Mixing speed

- up to 50 m/s

- Mixing capacity

- High throughput

- Retention time

- Extremely short

- Granulation size

- 100 µ - 1.5 mm

- Liquid addition

- Tangentially or via hollow shaft

- ATEX conformity

- 2014/34/EU

- Temperature control

- Jacket available

- Wear protection

- Mixing elements protected

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Easy operation and cleaning

- Mixing mechanism

- Concentric ringlayer with high peripheral speed

- Liquid addition

- Tangentially placed liquid pipes or hollow shaft

- Granulation control

- Via liquid quantity and process parameters

- Shear intensity

- Adjustable mixing tools

- Versatile applications

- Mixing, dispersion, breaking up, moistening, glue application, paste preparation, compaction, granulation, agglomeration, remixing

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Liquid viscosity

- High mixing flexibility for various viscosities

- Compact footprint

- Yes

- Discharge method

- Continuous

- Mixing Tool Adjustment

- Adjustable according to application

- Liquid Addition Method

- Tangentially via drum wall or hollow shaft

- Temperature Control Jacket

- Available for process control

- Mixing Drum Lining

- Wear, corrosion, and anti-adhesion protection

- ATEX Conformity

- 2014/34/EU directive

- Selection of Materials

- Materials in contact with product

- Use of Mixing Elements

- Application-specific selection

- Wear Protection

- Mixing elements wear protection