Static fluid bed dryer for powder and granular materials

Achieve optimal moisture control in powder and granular products, ensuring quality and consistency, with a high-capacity fluid bed dryer that excels in continuous operations.

Efficiently Dries and Cools Powders and Granules

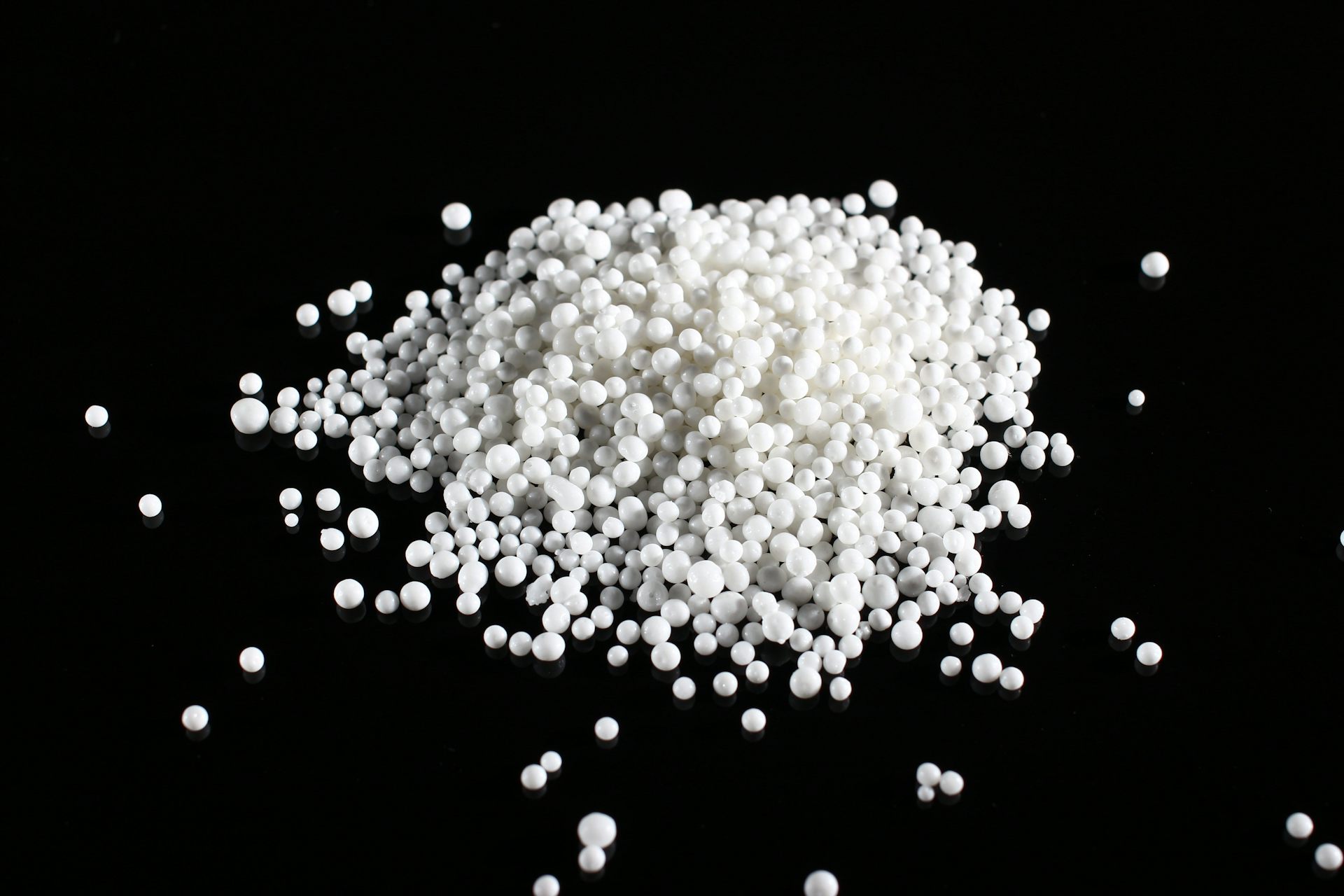

The Static Fluid Bed Dryer from GEA is designed for high-efficiency drying and cooling across a variety of industries including pharmaceutical, chemical, and food processing. This equipment fluidizes materials on a cushion of air or gas, allowing for uniform heat and mass transfer. It’s particularly effective for applications involving powders and granules, such as milk powder, detergent granules, and pharmaceutical tablets, ensuring precise moisture removal.

This dryer supports continuous, high-capacity operations and features a high temperature design for non-heat sensitive products, optimizing operational efficiency and reducing energy consumption. The system is PLC-controlled, enabling seamless integration into existing production lines with the potential for remote monitoring. Available with multiple zones and temperature settings, it can adapt to specific process requirements, making it highly versatile.

GEA’s Static Fluid Bed Dryer conforms to industry hygiene standards, with options for easy maintenance via removable bed plates and cleaning systems, minimizing downtime. Fabricated from materials that withstand corrosive environments, it ensures long operational life and compliance with regulatory certifications like GMP, essential for pharmaceutical applications. Customizable features allow engineering adjustments to meet unique production demands.

Benefits

- Enhances production efficiency with continuous, high-capacity operation.

- Optimizes energy savings through dynamic fluidization and controlled temperatures.

- Ensures product quality and compliance with hygienic standards in sensitive applications.

- Minimizes maintenance downtime with easily removable and cleanable components.

- Adapts to a wide range of materials, including non-heat sensitive products, with customizable settings.

- Applications

- Crystalline materials, Non-heat sensitive products, Powder production, Granular materials, Hygienic applications, Chemical bulk products

- End products

- Pharmaceutical tablets, Ammonium nitrate, Milk powder, Baking soda, Sugar crystals, Vitamin c crystals, Detergent granules, Instant coffee granules, Flour powder, Fertilizer granules

- Steps before

- Grinding, Emulsification, Purification, Mixing

- Steps after

- Cooling, Secondary drying, Packing, Coating

- Input ingredients

- powder, crystalline materials, granular materials, wet powder chemical bulk products

- Output ingredients

- dried powder, cooled powder, processed powder, non-heat sensitive products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Fluidizing Gas Velocity

- Sufficient to support particle weight

- Heat Transfer Rate

- Very high due to intimate particle contact

- Production Capacity Turndown Ratio

- High

- Temperature Capability

- High inlet temperatures for non-heat sensitive products

- Distributor Plate Design

- Ensures even distribution of fluidizing gas

- Material Behavior

- Free-flowing boiling liquid-like state

- Gas Recycle Option

- Open circuit partial gas recycle

- Drying/Cooling Zones

- Multiple zones and stages

- Thermal Duty Supply/Removal

- Up to 90% by contact heat exchange tubes

- Bed Plate Removability

- Easily removable bed plates

- Working Mechanism

- Fluidized bed drying

- Integrated Steps

- Drying and cooling

- Automation Level

- PLC

- Batch vs. Continuous Operation

- Continuous

- Energy Efficiency

- High thermal efficiency

- Cleaning Method

- Manual or CIP

- Airflow Control

- Even distribution via distributor plate

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Moisture removal type

- Surface and bound moisture

- Particle size distribution

- Powder, crystalline, granular

- Temperature tolerance

- High temperature

- Material cohesiveness

- Varied cohesiveness

- Product sensitivity

- Non-heat sensitive

- Product type

- Powder, chemical bulk products

- Design Variations

- Stirred Fluid Beds, Deep Fluid Beds, High Temperature Fluid Beds, Contact Tubes and Plates, Multiple Zones and Stages, Integral Drying/Cooling

- Gas Distribution System

- Even Distribution via Distributor Plate

- Residence Time

- Extended or Flexible

- Temperature Control

- Multi-zone with various temperatures

- Construction Material

- Brick, Castable, Metallic Lined Washable Refractory

- Gas Circuit Design

- Open Circuit, Partial Gas Recycle, SSD

- Configuration

- Plug Flow or Well Mixed, Straight Sides or Expanded Canopy

- Heat Exchange

- Contact Heat Exchange Tubes within Deep Fluidized Bed

- Maintenance

- Easily Removable Bed Plates