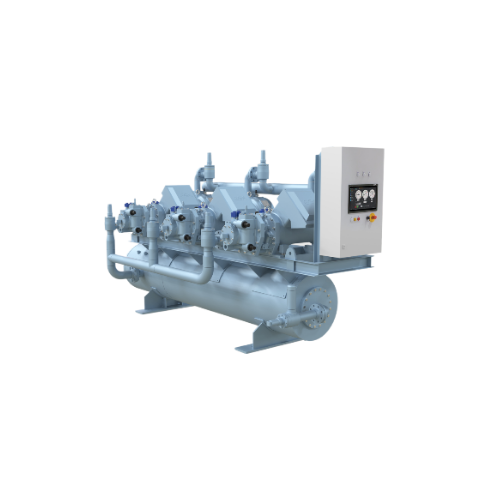

Industrial refrigeration screw compressor

Maximize cooling efficiency and ensure precise temperature control in your operations with a compact, high-speed screw compressor designed for effective cold chain management and energy savings throughout your production line.

Reduces Energy and Controls Industrial Refrigeration

The GEA Grasso M series from GEA Group offers a line of packaged screw compressor systems designed for the demanding environments of food and beverage processing, pharmaceuticals, chemicals, and building climatization. This system excels in efficiency, reducing power consumption by 3 to 5% compared to previous models, thanks to high-speed motors with a variable range from 1,000 to 4,500 rpm and the elimination of the need for an oil pump. The equipment supports applications such as cooling and refrigeration, with capacities spanning 219 to 879 kW, making it versatile for producing end-products like frozen vegetables and carbonated drinks. This system integrates seamlessly into existing production lines with its compact footprint, automated stepless capacity control, and user-friendly GEA Omni control panel. Maintenance is minimal due to extended intervals allowed by innovative component designs, further enhancing its cost-effectiveness. Designed for continuous, high-speed operations, the GEA Grasso M ensures energy efficiency and reliability while meeting rigorous industrial demands.

Benefits

- Minimizes operational costs with energy reductions of up to 5%.

- Enhances production flexibility with variable-speed motor control.

- Decreases maintenance frequency, lowering service costs and downtime.

- Integrates efficiently with existing systems, saving floor space.

- Provides precise temperature control essential for sensitive applications.

- Applications

- Chemicals, Food and beverage processing, Building climatization, Pharmaceuticals

- End products

- Temperature-controlled office environments, Frozen vegetables, Packaged pharmaceuticals, Synthetic resins, Industrial solvents, Hvac systems for large commercial buildings, Carbonated soft drinks, Dairy products

- Steps before

- Cooling, Pre-cooling, Temperature Regulation, Initial Temperature Setting

- Steps after

- Storage, Temperature Monitoring, Packaging, Distribution

- Input ingredients

- R717 refrigerant, electricity, variable speed drive motors

- Output ingredients

- cooled air, refrigeration, reduced energy consumption, efficiency

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Speed

- 1, 000 – 4, 500 rpm

- Cooling Capacity

- 219 to 879 kW

- Power Consumption Reduction

- 3% to 5% less than predecessors

- Compressor Type

- Single-stage screw compressor

- Variable Speed Range

- 1, 000 – 4, 500 rpm

- Cooling Medium

- R717

- Footprint

- Compact

- Capacity Control

- Stepless via frequency inverter and/or slide system

- Control Panel

- GEA Omni control panel with 15.6" touch screen

- Model Range

- 8 models

- Energy efficiency

- 3 to 5% less power consumption

- Automation level

- GEA Omni control panel

- Compact footprint

- Small, reduced complexity design

- Variable speed range

- 1, 000 – 4, 500 rpm

- Stepless capacity control

- Frequency inverter / slide system

- Part-load efficiency

- High efficiency for low part-load requirements

- Maintenance intervals

- Prolonged maintenance intervals

- Oil pump operation

- Operates without oil pump in common conditions

- Total cost of ownership

- Lowered through energy savings and service efficiency

- Cooling capacity range

- 219 to 879 kW

- Speed range

- 1, 000 – 4, 500 rpm

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Application areas

- Food, Beverage, Pharma, Chemical, Climatization

- Compact footprint

- Very small

- Control panel type

- GEA Omni control panel with high-definition 15.6" touch screen

- Discharge method

- Compatible with many industrial applications

- Control panel type

- GEA Omni high-definition 15.6" touch screen

- Speed range

- 1, 000–4, 500 rpm

- Stepless capacity control

- Via frequency inverter and/or slide system

- Motor type

- High speed motors with variable speed drive