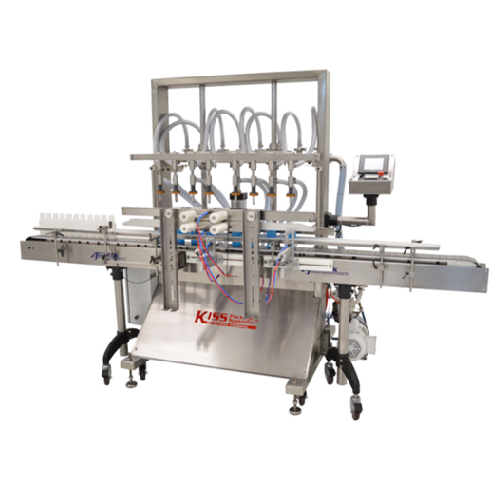

Automatic pressure overflow filler for low to medium viscosity liquids

Ensure consistent fill levels for low to medium viscosity liquids with precision-engineered nozzles, tackling the challenge of uniformity in visually demanding products, while safely managing foam and fumes in flammable environments.

Ensures Consistent Liquid Level in Containers

The APOF Series from Accutek Packaging offers a robust solution for achieving uniform fill levels in containers, crucial for maintaining product consistency on retail shelves. This automatic pressure overflow filler employs precision-engineered nozzles that ensure accurate liquid dispensing, making it ideal for low to medium viscosity liquids, including food products, personal care items, and flammable liquids. It supports a wide array of end-products such as salad dressings, olive oil, and household chemicals. With configurations available in 6, 8, 10, and 12 head models, along with an option for high-speed rotary filling, it’s designed for scalability in operations. The APOF Series incorporates pneumatic operation for safe handling of flammable materials, while its diving head nozzles minimize foam and drips, optimizing efficiency and cleanliness. Crafted with stainless steel contact parts, it supports rigorous sanitation protocols. Easy bottle shape and product changes enhance operational flexibility, and optional features like buffer tanks, container neck locators, and safety enclosures enable further customization to match specific production needs. Operating smoothly with 100 PSI air requirements and optional electrical configurations, it integrates seamlessly into existing production lines, offering reliable performance for diverse industries.

Benefits

- Maintains uniform product presentation by ensuring consistent fill levels in every container.

- Enhances operational safety through pneumatic operation that handles flammable liquids.

- Reduces production line downtime with quick and easy changeovers between bottle shapes and products.

- Meets sanitation standards with autoclave-compatible stainless steel product contact parts.

- Minimizes waste and spillage with precision-engineered nozzles that control foam and drips effectively.

- Applications

- Ink, Brine, Thin dressings, Makeup remover, Personal care products, Bottled water, Household chemicals, Low to medium viscosity liquids, Liquid cleaners, Oils, Flammable liquids, Bleach, Food products, Industrial chemicals, Alcohol, Water-based solutions

- End products

- Glass cleaner, Olive oil, Hair conditioner, Latex paint, Salad oil, Mineral water, Laundry bleach, Marinades, Salad dressings, Soy sauce, Mouthwash, Micellar water, Isopropyl alcohol, Tattoo ink, Shampoo, Pickling brine, Acetone, Floor cleaner

- Steps before

- Unscrambling, Rinsing, Washing

- Steps after

- Capping, Labeling, Packaging, Inspection, Coding

- Input ingredients

- low to medium viscosity liquids, flamable liquids, acetone, light paints, bottled water, food coloring, vegetable oil, liquid cleaners, petroleum oils, ink, light makeup remover, alcohol, bleach, brine

- Output ingredients

- filled containers, consistent visual fill level

- Market info

- Accutek is known for manufacturing high-quality engineered-to-order (ETO) equipment, specializing in custom automation and packaging solutions. They are reputed for their innovation, reliability, and ability to meet complex industrial needs.

- Height

- 78 inches

- Length

- 120 inches

- Width

- 56 inches

- Weight

- 1100 lbs. (498.95 kg)

- Speed

- Up to 120 CPM

- Fill Size

- 2oz-5L

- Viscosity Range

- 200 cps (centipoise)

- Electrical Requirements

- 220 or 240 VAC, single phase, 60 hertz (120 VAC available)

- Air Requirements

- 100 PSI, 5-10 CFM

- Foamy Product

- Yes

- Corrosive Product

- Yes

- Heated Product

- Yes

- Particulates

- No

- Working mechanism

- Automatic pressure overflow filling

- Automation level

- Automatic

- Diving head

- Reduces foam, drips, and fumes

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Quick and straightforward

- Pneumatic operation

- Yes

- No drip nozzles

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Autoclavable

- Abrasion resistance

- Stainless steel construction

- Density/particle size

- Suitable for 0.5–2.5 g/cm³

- Machine footprint

- 78" H x 120" L x 56" W

- Weight

- 1100 lbs. (498.95 kg)

- Frame material

- Rugged stainless-steel

- Nozzle configuration

- 6, 8, 10, 12 head

- Nozzle material

- Stainless steel or Hastelloy

- Fill size

- 2oz-5L

- Discharge method

- Diving head

- Container neck locator

- Available

- Buffer tank

- With stainless steel valve

- Drip tray

- Available

- Indexing

- Star wheel

- Foam control

- Bottom up fill nozzles

- Nozzle Types

- Stainless steel or Hastelloy

- Head Configurations

- 6, 8, 10, 12

- Safety Enclosures

- Available

- Product Contact Parts Material

- Stainless Steel / Autoclavable

- Neck Locator

- Container neck locator

- Drip Tray

- Available

- Pneumatic Operation

- Available

- Buffer Tank with Valve

- Stainless Steel

- Bottom Up Fill Nozzles

- Foam Control

- High Temperature Upgrades

- Available

- Star Wheel Indexing

- Available