Layer preparation system for high-speed palletizing

Optimize your palletizing process with a system that ensures precise layer preparation, maintaining product integrity and maximizing efficiency in continuous high-speed operations.

Arranges and Prepares Product Layers

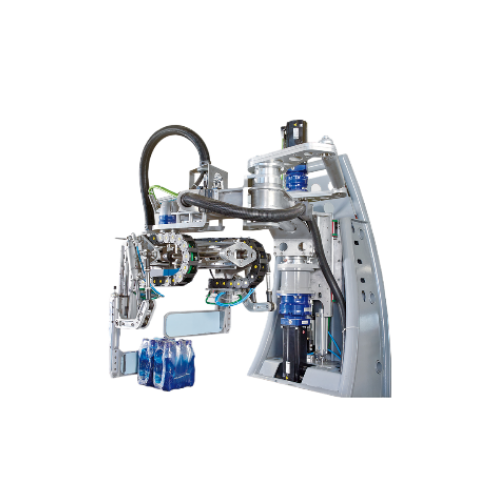

The Layer Preparation System Polaris EVO from GEA seamlessly integrates into your production line, specializing in arranging product layers with precision and efficiency. Employing a SCARA-based robot configuration, this system ensures continuous operation by preparing layers without interruption. The design enables gentle handling, reducing shock and maintaining product integrity. Ideal for industries such as food and beverage, pharmaceuticals, and packaging, it accommodates various end-products like bottled water, snack foods, and liquid pharmaceuticals. The Polaris EVO handles up to 133 packs per minute with its adjustable pneumatic and motorized gripping heads, offering flexibility for different pack types and sizes. This modular system can be configured for medium to high-speed lines, enhancing production throughput while maintaining a compact footprint. Its PLC-controlled automation supports seamless integration, optimizing the downstream palletizing process. Available in corrosion-resistant materials, Polaris EVO ensures durability in demanding environments, while easy access and lower moving bulk simplify maintenance and operation. With engineering support for customization, the Polaris EVO addresses specific production needs efficiently.

Benefits

- Enhances production efficiency with continuous layer preparation, minimizing downtime.

- Increases speed and flexibility by accommodating various pack sizes and configurations.

- Streamlines installation and maintenance with a compact, accessible SCARA configuration.

- Optimizes energy use by locating main motors in a fixed position, reducing load on the arm.

- Improves product integrity through gentle handling, preventing product damage during layer preparation.

- Applications

- Food, Beverages, Chemicals, Personal care, Gas, Energy, Oil, Environment, Home, New food, Dairy, Pharmaceuticals

- End products

- Recyclable packaging materials, Renewable energy components, Skincare lotions, Liquid pharmaceuticals, Bottled water, Detergents, Snack foods, Packaged cheese, Packaged natural gas, Plant-based protein products, Packaged oils, Soft drinks

- Steps before

- Packaging, Sorting, Conveying

- Steps after

- Palletizing, Wrapping, Shipping

- Input ingredients

- packs, products, production lines

- Output ingredients

- whole layer of products, prepared layers, optimized palletizing patterns

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Production capacity

- Up to 133 ppm (with 2 heads)

- Automation

- Continuous working mode

- Configuration

- SCARA-based

- Motion range

- Horizontal (x-y) and vertical (z)

- Handling type

- Gentle handling

- System type

- Modular

- Working Mechanism

- SCARA-based configuration

- Integrated Steps

- Continuous working mode

- Batch vs. Continuous Operation

- Continuous

- Changeover Time

- Format changeover with vertical axis adjustment

- Automation Level

- PLC/SCADA

- Energy Efficiency

- Optimized through reduced inertia

- Cleaning Method

- Gentle handling to avoid shocks

- Flexibility

- Connects to different gripping heads

- Abrasion resistance

- Shock-proof material coating

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Easy access design

- Density/particle size

- Adjustable grip for different pack sizes

- Machine footprint

- Compact

- System configuration

- Modular

- Operating mode

- Continuous working mode

- Handling robot type

- SCARA-based configuration

- Gripping head type

- Pneumatic / Motorized / Plate overtake cycle

- Gripping flexibility

- Single or multiple packs

- Axis movement

- Horizontal x-y and vertical

- Control panel type

- SCADA / HMI

- Integration possibilities

- SCARA-based configuration

- Gripping head type

- Pneumatic / Motorized

- Modularity

- Single unit or series installation

- Footprint

- Compact

- Gripping flexibility

- Front or side pick-up