Corn starch drying solutions

Ensure precise moisture control and maintain product integrity in your corn starch processing with advanced drying solutions that balance energy efficiency and safety.

Dries and Conditions Corn-Based Products Efficiently

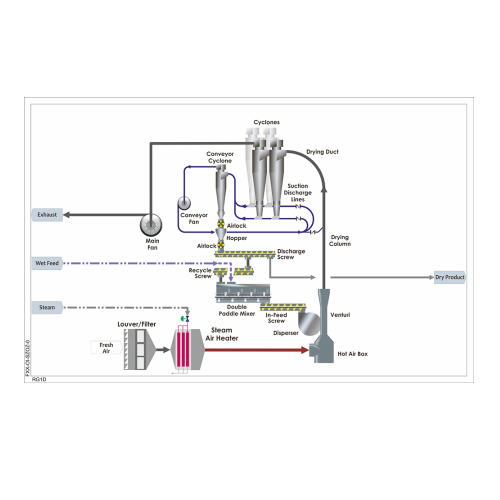

Dedert’s Corn Starch Drying System offers engineered-to-order solutions tailored for corn wet milling companies seeking precise moisture control. The system employs both flash and ring drying technologies, enabling efficient drying of native and modified corn starch. Utilizing an Open-Circuit configuration, it ensures consistent product quality by maintaining low-temperature environments, minimizing thermal stress and contamination risks. To handle the delicate nature of corn starch, the system integrates re-closable vent doors for safety in deflagration events, and offers automated, PLC-controlled operation with easy process integration. Its capability to process diverse products, such as corn germ, gluten meal, and feed, makes it versatile across multiple sectors including food, biofuels, and plant-based protein industries. Crafted in corrosion-resistant materials, it guarantees durability, while comprehensive customization options ensure it fits seamlessly into existing facilities.

Benefits

- Enhances product quality by preventing contamination and thermal degradation.

- Increases safety with robust design and re-closable vent doors for deflagration protection.

- Saves energy with efficient drying configurations tailored to product needs.

- Seamlessly integrates into existing lines with easy automation and process control.

- Accommodates a range of corn-based products, supporting diverse industry applications.

- Applications

- Grains, Chemical, Plant-based protein, Food ingredients, Starch, Biofuel

- End products

- Corn gluten feed, Modified corn starch, Corn gluten meal, Corn germ, Native corn starch

- Steps before

- Corn Wet Milling, Evaporation, Process Design, Feed Conditioning

- Steps after

- Product Collection, Packing, Quality Control

- Input ingredients

- corn germ, corn gluten meal, corn gluten feed, corn starch, wet corn

- Output ingredients

- native corn starch, modified corn starch, corn germ, corn gluten meal, corn gluten feed

- Market info

- Dedert is known for its expertise in designing and supplying advanced drying and evaporation technologies, serving the chemical, food, and other processing industries with innovative and efficient engineered-to-order solutions.

- Drying Method

- Flash Dryer / Ring Dryer

- Configuration

- Open-Circuit (OC)

- Heat Environment

- Low Temperature

- Heat Source

- Indirect Steam-Heating

- Residence Time

- A few seconds

- Airflow System

- Ambient Fresh Air

- Drying Sensitivity

- Thermal and Mechanical Work

- Safety Feature

- Re-closable Vent Doors

- Dryer Shape

- P-Type Shape for Ring Dryer

- Solids Circulation

- Internal Circulation (Ring Dryer)

- Drying configuration

- Open-Circuit (OC)

- Dryer type

- Flash Dryer / Ring Dryer

- Heat source

- Indirect steam-heating

- Residence time

- A few seconds

- Contamination prevention

- Ambient fresh air, clean drying medium

- Deflagration safety

- Robust design, re-closable vent doors

- Automation level

- Not specified

- Process adaptability

- Suitable for temperature and moisture sensitive materials

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Feed/Discharge Method

- Flash dryer / Ring dryer

- Shape and Size

- "P" shape for Ring Dryer

- Discharge Method

- Full discharge to product collection system

- Vent Design

- Re-closable vent doors