Ploughshare mixer for batch operation

Achieve superior mixing quality with a system designed for rapid batch operations. Experience precise, gentle treatment across diverse materials while ensuring reproducibility and efficient integration into any production line that demands high throughput and consistent results.

Processes and Mixes Diverse Industrial Materials

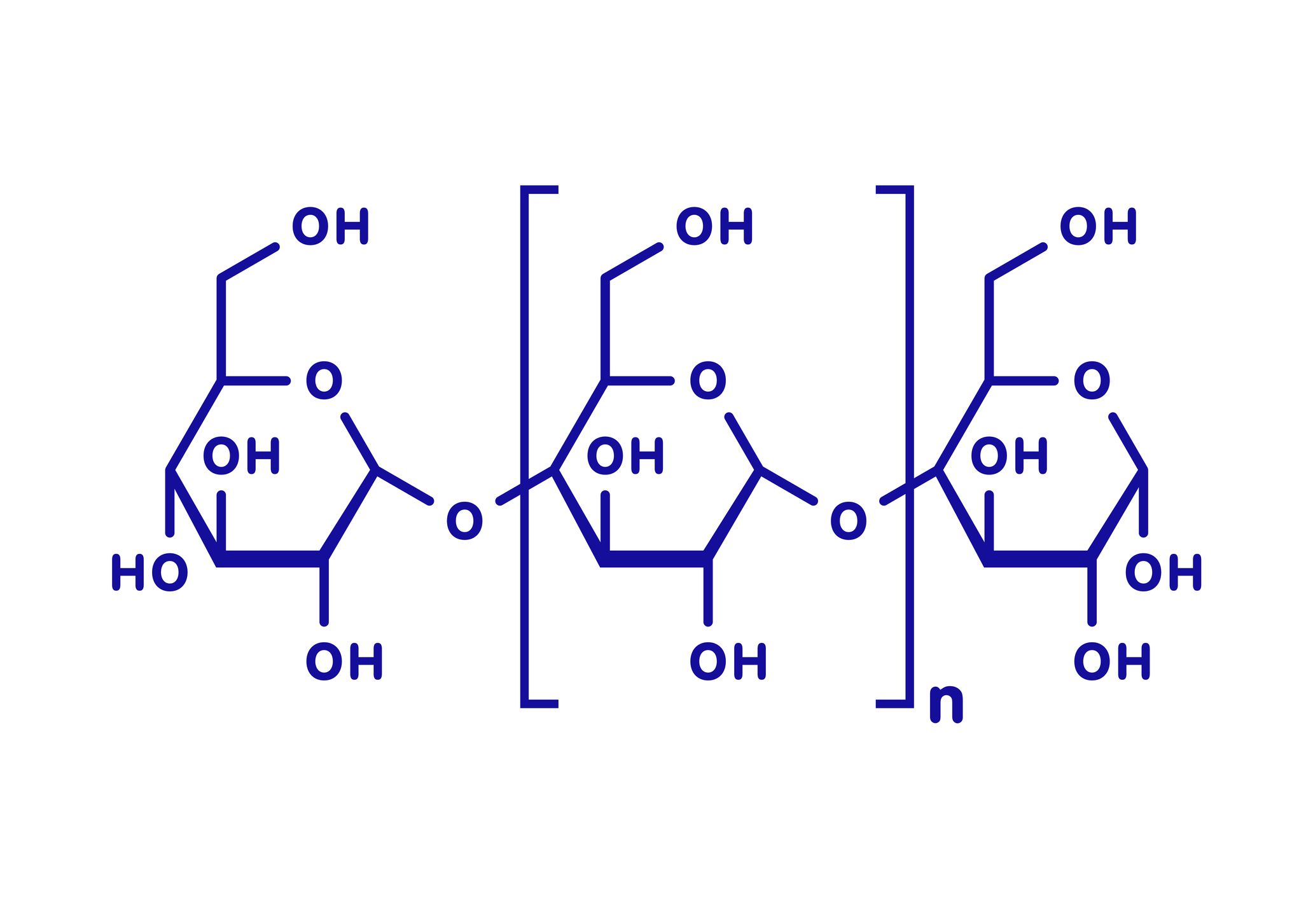

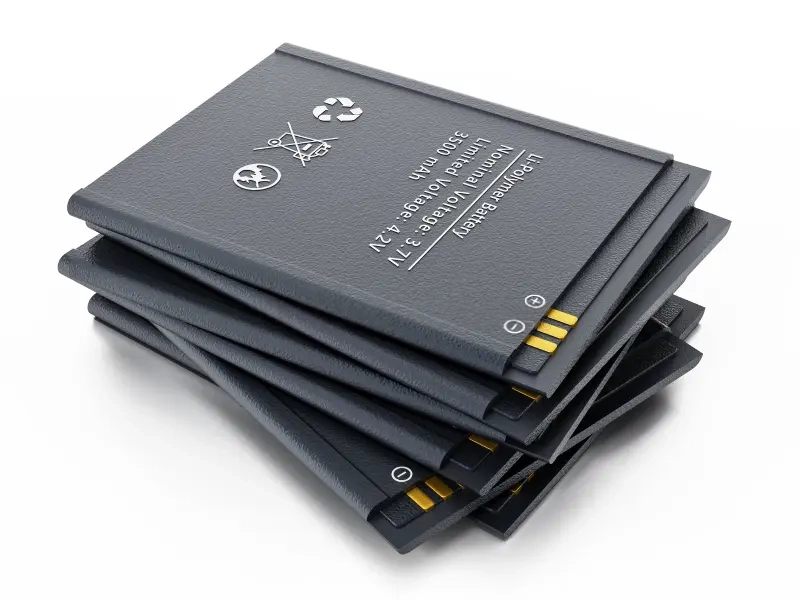

The Ploughshare® Mixer for batch operation from Gebrüder Lödige Maschinenbau GmbH offers unmatched versatility and precision in mixing, drying, and coating processes. Uniquely suited for industries such as chemical production and battery fabrication, it employs a horizontal mixing shaft that generates a mechanical fluid bed, effectively ensuring homogeneous mixing even with diverse material densities. Ideal for producing plasterboards, EPS granules, and lithium-ion battery cathode materials, this mixer handles solid, powder, and slurry types seamlessly. Its robust construction allows for additional choppers to increase turbulence and ensures efficient integration with existing production lines through PLC control systems. Further enhancing operational efficiency, the mixer is designed for minimal residue discharge and low maintenance, featuring wear-resistant components and options for ceramic or tungsten-carbide lining. Certified for various industry standards, it supports a clean-in-place (CIP) system for straightforward maintenance and effortless compliance with stringent industry regulations.

Benefits

- Ensures homogeneous mixing of diverse materials, enhancing product quality and consistency.

- Minimizes residue discharge, maximizing material utilization and efficiency.

- Lowers maintenance costs with durable, wear-resistant components.

- Supports energy-efficient operations through customizable speed adjustments.

- Facilitates regulatory compliance with industry-standard certifications.

- Applications

- Polysaccharides, Animal feed, Pigments and dyes, Metallurgy, Friction linings, Detergents, Raw materials, Building materials, Refractory materials, Chemical industry, Fertilisers, Environment, Plastics, Batteries

- End products

- Silicon carbide abrasives, Powder coatings, Lithium-ion battery cathode materials, Graphite electrodes, Eps granules, Ceramic tiles, Liquid laundry detergents, Npk fertilizers, Mortars, Plasterboards, Cattle feed pellets, Brake pads, Firebrick blocks, Titanium dioxide pigments

- Steps before

- Purification, Grinding, Emulsification, Material preparation

- Steps after

- Packing, Coating, Granulation, Drying, Cooling, Storage

- Input ingredients

- bulk solids, powdery products, grainy materials, fibrous materials, pumpable products, liquid components, binding agents, metal ores, sintering mixes, carbon and graphite compounds, raw materials for ceramics, non-ferrous metals, glass melts, welding agents, sanding grain mixes, salts, EPS, master batches, PVAL, polyolefins, natural rubber, solvent-based adhesives, plasters, mortars, screed, blast-furnace cement, gypsum, plasterboards, adhesives, fillers, ground treatment materials, sludge, slurry, dust, ash, contaminated substances, battery masses, friction linings, fertilisers, animal feed, pigments and dyes, fire-proof compounds, detergents, wood substances, ligno substances

- Output ingredients

- high-quality mixes, homogeneous distribution, coated particles, granulated products, intensive particle separation, high throughput volumes, residue-free discharge products, fire-proof products

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Mixing quality

- Extremely high

- Mixing time

- Short

- Batch operation

- Yes

- Residue-free discharge

- Yes

- Peripheral speed of shovels

- Coordinated for task

- Batch size

- Flexible (large throughput)

- Discharge method

- One-door system

- Residual material

- < 0.1%

- Liquid addition

- Pipes/nozzles for diverse feeding systems

- Granulation

- Automatic with liquid addition

- Particle separation intensity

- High

- Capacity for powdery/grainy/fibrous

- Yes

- Capacity for pumpable products

- Yes

- Heating/cooling options

- Jacket available

- Automation

- Modern, user-friendly control system

- Working mechanism

- Ploughshare® technology

- Integrated steps

- Mixing and fluid process

- Batch operation

- Yes

- Gentle product treatment

- Yes

- Mixing time

- Short

- Batch reproducibility

- Yes

- Residue-free discharge

- Yes

- Multi-stage processes

- Yes

- Cleaning in Place (CIP) principles

- Optional (WIP systems)

- Liquid addition capability

- Yes

- Granulation capability

- Yes

- Coating capability

- Yes

- Energy efficiency

- High

- Changeover time

- Short due to easy accessibility

- Automation level

- Optional control systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank shape

- Horizontal, cylindrical drum

- Mixing elements

- Ploughshare® Shovels

- Discharge method

- One-door discharging system

- Mixing shaft arrangement

- Horizontal

- Mixer component accessibility

- Easy accessibility

- Inspection door

- Large inspection door

- Construction material

- Structural steels to stainless steels

- Mixing process

- Multi-stage processes in one machine

- Control panel type

- Modern, user-friendly control system

- Jacket for heating and cooling

- Available

- Chopper devices

- Optional

- Material of construction

- Structural steels to stainless steels to special materials

- Liquid addition system

- Pipes or nozzles

- Batch mixer feeding door

- Large for manual feeding

- Inspection door

- Large for easy accessibility

- Explosion protection

- Suitable for nearly all zones

- Cleaning systems

- WIP (Washing in Place)