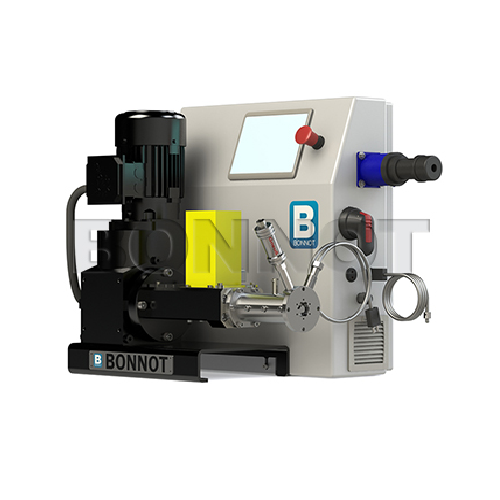

Laboratory extruders for feasibility studies and r&d

Optimize your testing with laboratory extruders designed for precise material handling, offering advanced temperature and pressure control to enhance R&D outcomes.

Forms and Tests Small Batch Extrusions

The laboratory extruders from The Bonnot Company address the specific needs of research and development environments by providing precise control over material extrusion. These CE-compliant units utilize the company’s proprietary twin packer technology to ensure positive material ingestion. Tailored for multiple applications, they are equipped for temperature control and pressure monitoring, making them ideal for handling diverse materials such as bulk molding compounds, carbon, and food. With outputs ranging from 5 to 150 pounds per hour, these extruders are versatile for bench-top and pilot-scale operations. Each model, from the 1 Series to the 2 Series, integrates seamlessly into existing production lines with optional touchscreen controls, high torque gear motors, and quick-release connections for efficient maintenance. Housed in stainless steel, these extruders ensure durability and chemical resistance, meeting rigorous testing protocols across industries like chemical processing, food manufacturing, and polymer development. Optional features provide customization and data collection capabilities, supporting complex research projects and scale-up processes.

Benefits

- Facilitates precise material testing and scale-up, accelerating research and development timelines.

- Enhances material handling efficiency with twin packer technology for consistent extrusion.

- Minimizes operational disruption with quick-release connections for fast maintenance.

- Adapts to a broad range of materials, supporting diverse industry applications.

- Improves data accuracy and process control with optional touchscreen and data collection features.

- Applications

- Food, Clay, Rodenticide, Bulk molding compound, Hydrocolloid, Catalyst, Carbon, Firelog, Rubber, Sealant

- End products

- Ceramic pottery, Rodent bait blocks, Compressed sawdust firelogs, Graphite electrodes, Automotive body panels, Catalytic converters, Rubber gaskets, Silicone sealant, Xanthan gum, Protein bars

- Steps before

- Feasibility Testing, Material Preparation, Screw Geometry Configuration

- Steps after

- Data Collection, Profile Creation, Cutting with Extruder Cutter

- Input ingredients

- bulk molding compound, carbon, catalyst, clay, firelog, cold forming materials, food forming materials, hydrocolloid, rodenticide, rubber, sealant

- Output ingredients

- extruded products, formed profiles, various profiles

- Market info

- The Bonnot Company is known for its expertise in manufacturing industrial extruders and cutting equipment, specializing in engineered-to-order solutions for various industries, including food, chemical, and ceramic sectors, with a reputation for quality and innovation.

- Output

- 1 Series

- Output

- 2 Series

- Motor Power

- 0.5 HP - 1 HP

- Motor Power

- 2 Series TP

- Temperature,Pressure Monitoring

- Available

- Control Panel

- Touchscreen / Discrete

- Data Collection

- Optional

- Hopper Opening

- 1 Series

- Hopper Opening

- 2 Series

- Layout

- 1 Series

- Layout

- 1 Series TP

- Layout

- 2 Series

- Automation level

- Touchscreen PLC

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Various layouts (e.g., 14" x 9" x 21", 21" x 22" x 16", 43" x 54" x 35")

- Hopper opening

- 3" x 2.4" / 6" x 5"

- Motor power

- 0.5 HP - 1 HP / 10 HP

- Discharge method

- Quick Release Disconnect

- Control panel type

- Touchscreen PLC / Discrete

- Control panel type

- Touchscreen

- Temperature,Pressure Monitoring

- Yes

- Material Ingestion Aid

- Twin Packers

- Configuration Options

- Longer L/D, Different Screw Geometry, Forming Dies

- Barrel Type

- Jacketed