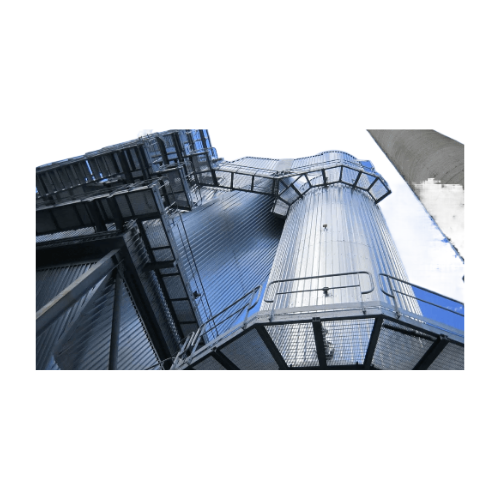

Venturi scrubber for fine particulate and aerosol separation

Achieve high separation efficiency of fine dust and aerosols with a Venturi scrubber that adapts to fluctuating gas streams, ensuring steady operation and minimal maintenance, while meeting stringent emission regulations.

Separates Particulates and Aerosols in Gas Streams

The Venturi Scrubber from GEA expertly combines efficiency and versatility to address emission control challenges in the chemical, iron, steel, and non-ferrous industries. Utilizing the Venturi effect, it efficiently separates fine particulates and aerosols from gas streams, adapting to variable flow rates in continuous operations. Predominantly applied for gas cooling, quenching, and conditioning, the scrubber ensures compliance with demanding emission limits while handling gas volumes up to 300,000 m³/h. Integration into existing production lines is seamless, supported by customizable nozzle arrangements and material options, including options for enhanced chemical and thermal resistance. Maintenance is minimal due to its robust design, enhancing reliability even under fluctuating gas conditions.

Benefits

- Optimizes emission control by effectively managing variable gas flows.

- Reduces downtime through continuous operation and low maintenance needs.

- Enhances process integration with customizable configurations and material options.

- Lowers operational costs with minimal pressure drop and energy-efficient design.

- Ensures compliance with stringent environmental regulations.

- Applications

- Steel industry, Chemical industry, Emission control, Non-ferrous industry, Iron, Gas treatment

- End products

- Copper dust, Ammonium sulfate, Particulate-laden emissions, Exhaust gases treatment, Lead dust, Aerosol sprays, Sulfuric acid, Aluminum dust, Hydrochloric acid, Zinc dust

- Steps before

- Gas collection, Pre-dedusting, Gas conditioning

- Steps after

- Centrifugal separation, Filtration

- Input ingredients

- gas containing fine particulate matter, aerosols, fluctuating gas streams, dust laden gases, industrial off-gas, raw gas

- Output ingredients

- cleaned gas, separated aerosols, fine dust removal, gaseous pollutants treated, high separation efficiency

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Separation efficiency

- High

- Gas volume flow rate

- 1 to 300, 000 m³/h

- Particle size separation

- Approximately 0.7 µm upwards

- Pressure drop

- 25 to 80 mbar

- Load control range

- 20% to 100%

- Configuration

- Vertical, inclined, or horizontal

- Scrubbing liquid injection

- Central nozzle or manifold nozzles

- Operating pressure drop for cooling/pre-dedusting

- Few mbar

- Gas flow adaptability

- Continuous adjustment for steady performance

- Particle separation method

- Impaction on washing media droplet

- Pressure drop

- 25 to 80 mbar at ambient pressure

- Scrubbing liquid injection

- Central or manifold nozzles

- Throat velocity

- High relative velocity between gas and liquid

- Separation efficiency

- High due to high relative velocity and liquid spray density

- Gas stream fluctuations

- Handles fluctuating gas streams effectively

- Operation mode

- Variable inlet flows with regulating cone

- Customizability

- Adaptable nozzle arrangement

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Variable

- Fits spatial and process requirements

- Scrubber Type

- Venturi Scrubber

- Orientation

- Vertical / Inclined / Horizontal

- Material

- Variety of materials for chemical and thermal resistance

- Venturi Throat

- Equipped with a regulating cone

- Nozzle Arrangement

- Central nozzle or manifold nozzles

- Gas Volume Flow Rate

- 1 to 300, 000 m³/h

- Pressure Drop

- Range from 25 to 80 mbar

- Particle Sizes Separated

- From approximately 0.7 µm upwards

- Material selection

- Nearly all materials for chemical and thermal resistance

- Nozzle arrangement

- Adaptable for specific applications

- Scrubbing liquid choice

- Customizable for specific gaseous pollutant treatment

- Spatial arrangement

- Vertical, inclined, or horizontal mounting

- Regulating cone

- Variable inlet flow regulation