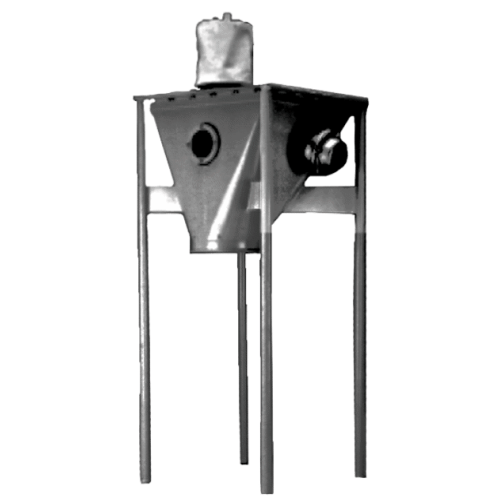

Aerolock surge hopper for precise bulk material management

Optimize your production with a surge hopper designed to ensure efficient bulk material storage, venting, and precise level indication—ideal for maintaining smooth flows and reducing operational hiccups in both batch and continuous processes.

Facilitates Storage, Venting, and Discharge Processes

The Aerolock™ Surge Hoppers from Coperion K-Tron provide a robust solution for the efficient handling of various materials such as solids, powders, and granules. Constructed from both carbon and stainless steel, these hoppers are designed to integrate seamlessly with Coperion’s Aerolock rotary valves for precise material flow. They feature a cloth filter vent and a sidewall coupling for level indicators, ensuring optimal venting and level measurement. Ideal for plastics, chemicals, food, pet food, pharmaceutical, and nonwoven industries, the hoppers facilitate both batch and continuous operations. With customizable inlet configurations and sufficient clearance for downstream equipment like shearing protectors and outlet adapters, they are engineered for flexibility and ease of integration. These hoppers also offer durable construction options to withstand challenging industrial environments, ensuring long-term reliability and reduced maintenance.

Benefits

- Enhances material handling efficiency by integrating seamlessly with Coperion Aerolock rotary valves.

- Reduces operational disruptions with reliable venting and level indication systems.

- Facilitates easy customization to suit specific processing requirements, minimizing installation time.

- Provides robust construction options that withstand rigorous industrial use, ensuring long-term reliability.

- Streamlines production line integration with adjustable clearance for downstream equipment.

- Applications

- Chemicals, Food, Nonwovens, Pet food, Plastics, Pharmaceutical

- End products

- Polyethylene pellets, Hot melt adhesives, Pharmaceutical tablets, Sap (superabsorbent polymers) for diapers, Pvc compounds, Pet food kibble

- Steps before

- Feeding, Material Loading, Bulk Material Handling, Pre-processing

- Steps after

- Discharge, Material Conveying, Processing, Batch Weighing

- Input ingredients

- bulk materials, various powders, particulates

- Output ingredients

- processed materials, controlled flow of materials

- Market info

- Coperion is known for its expertise in manufacturing industrial compounding and extrusion equipment, bulk materials handling systems, and services for various industries, such as plastics, chemicals, and food processing, with a strong reputation for innovative engineering solutions and customer support.

- Material

- Carbon steel, Stainless steel

- Connected Equipment

- Aerolock rotary valves

- Filter Type

- Cloth filter vent

- Level Indication

- Sidewall coupling for level indicator

- Observation Facility

- Sight glass in hopper wall

- Customization Option

- Field cut inlet, bolted lid without opening

- Mounting Feature

- Flanged to match round inlet

- Support Feature

- Support legs clearance for shear protector

- Batch vs. continuous operation

- Batch

- Integration with Aerolock rotary valves

- Yes

- Material level monitoring

- Sight glass and level indicator

- Cover customization

- Field-modifiable

- Ventilation system

- Cloth filter vent

- Level Detection

- Level indicator compatible

- Industry

- Plastics, Chemicals, Food, Pet Food, Pharmaceutical, Nonwovens

- Materials of Construction

- Carbon Steel, Stainless Steel

- Flange Designed

- Flanged to match round inlet Aerolock rotary valves

- Filter Vent

- Cloth Filter Vent

- Level Indicator Accommodation

- Coupling in sidewall for level indicator

- Sight Glass

- Sight glass in hopper wall

- Cover Type

- Bolted lid with optional opening

- Support Legs

- Sufficient clearance for shear protector, Aerolock rotary valve and outlet adapter

- Material construction

- Carbon steel, Stainless steel

- Cover customization

- Custom cover/no opening option

- Optional features

- Pulse clean filter