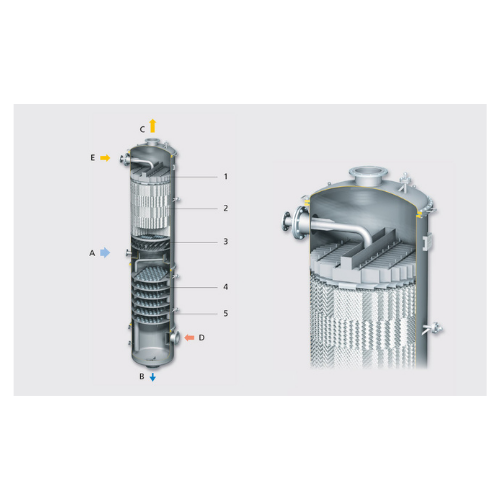

Industrial tray and packing column solutions

For efficient separation and product purification, tray and packing columns optimize distillation, fermentation, and rectification processes, ensuring high purity end products such as ethanol and active pharmaceutical ingredients.

Enables Efficient Liquid and Gas Separation

The Tray and Packing Columns from GEA are essential for achieving high-efficiency separation in chemical, food, and energy sectors. Designed to handle a range of liquid and gas applications, these columns utilize computer-modeled multi-stage distillation for precise product separation. Ideal for producing ethanol, purified water, and active pharmaceutical ingredients, they support continuous, skid-mounted, or pilot operations, ensuring versatility in integration. Available with energy-efficient reboilers and thermal recompression systems, these columns reduce steam consumption significantly. Constructed from corrosion-resistant materials, they comply with industry standards for reliability and safety. Custom configurations and on-site pilot testing ensure a tailored solution to meet your specific process requirements.

Benefits

- Maximizes separation efficiency, ensuring high product purity for stringent quality requirements.

- Reduces steam consumption, leading to lower operational energy costs.

- Offers flexible integration in continuous, skid-mounted, or pilot configurations to fit varying production scales.

- Supports diverse applications with customizable internals, accommodating a wide range of chemical and physical properties.

- Ensures operational safety and reliability with corrosion-resistant construction and compliance with industry standards.

- Applications

- Food, Personal care, Marine, Gas, Beverage, Refrigeration, Oil, Heating, Chemical, Pharma, Healthcare, Environment, Home, Dairy

- End products

- Cooking oils, Purified water, Ethanol, Active pharmaceutical ingredients, Ammonia, Dairy protein isolates, Biofuels, Edible oils, Refrigerant gases, Marine biofuels, Antiseptic solutions, Fragrance compounds, High-fructose corn syrup, Liquefied natural gas, Solvent recovery, Vaccine components, Essential oils

- Steps before

- Purification, Grinding, Feed Preparation, Concentration, Preheating

- Steps after

- Condensation, Cooling, Packing, Storage, Quality Control

- Input ingredients

- feed, steam, vapor

- Output ingredients

- bottom product, overhead product, reflux

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Column Type

- Tray and Packing Columns

- Feed Type

- Variable based on product characteristics

- Design Method

- Computer Modeling and Large Product Databases

- R,D Capability

- In-house Research and Development Centre

- Reboiler Type

- Various types depending on process parameters

- Distillation Plant Type

- Multiple Effect, MVR / TVR heated

- Skid Mounted Option

- Available for compact units

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- High

- Abrasion resistance

- Yes

- Column Type

- Tray and Packing Columns

- Control Panel Type

- Computer modelled

- Feed method

- Distributor

- Discharge method

- Bottom and Overhead product

- Pilot Plant Availability

- Mobile Units

- Internal design

- Customizable

- Control panel type

- PLC / HMI integrated

- Mobile unit capability

- Yes, pilot plants

- Column internals selection

- Flexible supplier options

- Custom column design

- Tailored to product characteristics