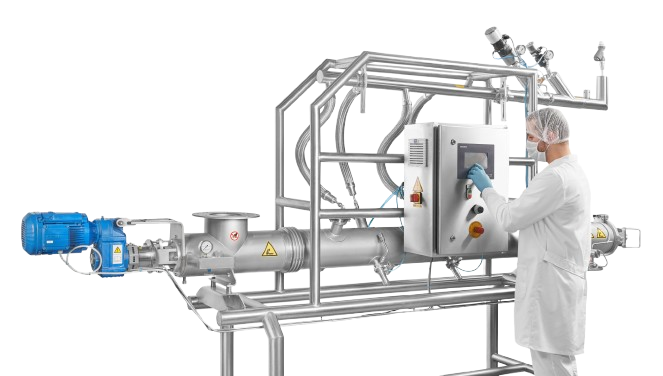

Cryogenic screw conveyor for food processing

Enhance your production line with a cryogenic screw conveyor that simultaneously conveys, cools, and mixes, ensuring precise temperature control and uniformity for delicate processes like coffee grinding and snack preparation.

Conveys, Cools, and Mixes Foodstuffs Efficiently

Dohmeyer’s cryogenic screw conveyor is engineered to enhance the efficiency of food and beverage production lines. This customized solution effectively conveys, cools, and mixes ingredients like coffee grounds, herbal teas, and snack items, ensuring precise temperature and texture control before grinding or further processing. Utilizing injected liquid nitrogen or CO2 dry ice, it offers uniform cooling and freezing. Designed for both continuous and batch operations, the conveyor features an accessible housing for straightforward cleaning and maintenance. Special paddles ensure a consistently mixed product. The material construction is optimized for food-grade applications, maintaining hygiene and reducing labor costs. Tailored to integrate seamlessly into existing processing lines, it offers flexibility for diverse production needs.

Benefits

- Enhances processing efficiency by integrating conveying, cooling, and mixing in one step.

- Minimizes labor costs and handling for improved operational hygiene.

- Ensures product consistency and quality with homogenous cooling and mixing.

- Simplifies maintenance with easy access design for quick cleaning.

- Supports both continuous and batch operations for versatile production demands.

- Applications

- Snacks, Herbs, Coffee, Foodstuffs

- End products

- Coffee grounds, Potato chips, Herbal tea blends, Tortilla chips

- Steps before

- Grinding, Blending, Mixing, Pre-cooling

- Steps after

- Grinding, Texture preparation, Temperature setting, Batch production, Continuous production

- Input ingredients

- foodstuffs, coffee, herbs, liquid nitrogen droplets, CO2 dry ice

- Output ingredients

- cooled foodstuffs, frozen foodstuffs, prepared texture products, temperature-adjusted products

- Market info

- Dohmeyer is renowned for manufacturing advanced cryogenic equipment, specializing in ultra-low temperature applications for various industries, including pharmaceuticals and food processing. They are recognized for their innovation, quality, and customer-focused engineered-to-order solutions.

- Cooling Option

- Cryogenic

- Automation

- PLC-controlled

- Cooling Medium

- Liquid Nitrogen/CO2

- Cleaning Method

- Easy access for manual cleaning

- Conveyor Customization

- Tailor-made housing

- Working mechanism

- Screw conveyor

- Cooling process

- Injected liquid nitrogen or CO2 dry ice

- Automation level

- Manual / PLC-controlled

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- Manual / Open housing for easy cleaning

- Abrasion resistance

- Yes

- Biological compatibility

- Suitable for food applications

- Cleanability

- Easy access for cleaning

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Product Handling

- Foodstuffs

- Batch vs. Continuous Operation

- Both

- Pre-processing

- Cooling/Freezing

- Machine footprint

- Customizable

- Cooling type

- Liquid nitrogen droplets / CO2 dry ice

- Discharge method

- End discharge

- Feeding method

- Horizontal / Upwards conveying

- Housing design

- Openable for cleaning

- Conveyor type

- Screw type

- Material construction

- Stainless steel

- Integration possibilities

- PLC / SCADA

- Paddle type

- Special paddles for homogenous mix

- Housing type

- Openable for easy cleaning

- Liquid injection system

- Nitrogen or CO2 injection