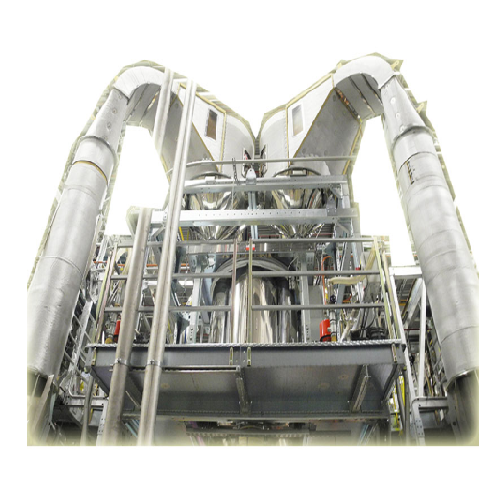

Destoner for roasted coffee beans

Ensure your coffee blends are free from impurities and stones with a high-precision destoner, crucial for maintaining the quality and consistency of your roasted coffee products.

Removes Impurities from Roasted Coffee Beans

The Destoner from Scolari Engineering is designed to enhance the quality of your roasted coffee production. By utilizing a precise air-flow separation method, it efficiently removes stones and debris from roasted beans, ensuring consistency in your final product. This equipment is vital for coffee roasting companies, offering applications in roasted and ground coffee, espresso beans, and specialty blends. It seamlessly integrates with your existing processing line, working alongside pneumatic conveyors and batching systems, and is computer-controlled for high operational efficiency. With its robust construction and attention to detail, the Destoner supports varying scales of production, supporting batch or continuous operations and maintaining quality in high-speed environments. The unit is available in corrosion-resistant materials, ensuring durability and long service life. For broader integration, the system is configurable to your specific processing requirements, supported by expert engineering consultation from Scolari Engineering.

Benefits

- Ensures consistent quality by removing impurities from roasted coffee beans.

- Increases production efficiency with seamless integration into existing lines.

- Reduces energy usage with an optimized pneumatic conveyance system.

- Minimizes equipment wear and extends service life with robust, corrosion-resistant materials.

- Supports flexible production needs with customizable configurations.

- Applications

- Roasted coffee beans, Ground coffee, Coffee products, Blended coffee

- End products

- Espresso coffee beans, Coffee pods, Instant coffee packets, Arabica roasted coffee, Specialty coffee blends, Mocha coffee blend, Espresso ground coffee, Italian roast coffee, French roast coffee, Breakfast blend coffee

- Steps before

- Roasting, Batching, Pneumatic Conveying

- Steps after

- Grinding, Packing

- Input ingredients

- roasted coffee beans

- Output ingredients

- blended roasted coffee, packed roasted coffee, ground roasted coffee

- Market info

- Scolari Engineering is known for designing and manufacturing custom-engineered drying systems and equipment, particularly for the food and agricultural industries, leveraging innovative technology and a strong reputation for quality and reliability.

- Automation

- Computer-controlled batching system

- Handling System

- Pneumatic pulse conveyors

- Blender Capacity

- Suitable for roasted bean blending

- Silos Capacity

- 4 to 18 silos per battery

- Batching Machine Type

- Weighing-batching machine

- Automation level

- Manual / PLC controlled

- Batch vs. continuous operation

- Batch

- Pneumatic conveying type

- Pneumatic pulse conveyors

- Electronic speed control

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Conveyance Method

- Pneumatic pulse conveyors

- System Footprint

- Customizable

- Silos Quantity

- 4 to 18 per battery

- Silos Design

- Roasted bean compatible

- Conveyance Method

- Pneumatic pulse conveyors

- Blender Inclusion

- Optional

- Control panel type

- Electronic speed control

- Integration possibilities

- Computer-controlled batching program

- Blender inclusion/exclusion

- Programmable via computer