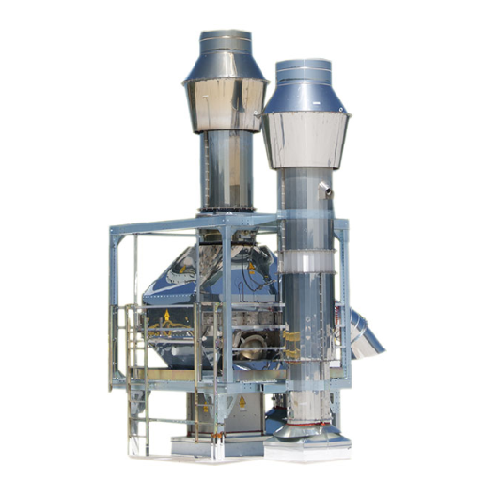

Catalytic converter for industrial coffee roasting

Optimize your coffee roasting with precise control and efficiency, ensuring consistent quality through advanced catalytic conversion technology designed to handle the unique challenges of dark and medium roasts.

Optimizes Roasting and Sampling for Espresso Coffee

The Catalytic Converter with 12 Drawers from Scolari Engineering is specifically engineered to enhance espresso and dark roast coffee production within industrial coffee roasting environments. It plays a critical role in ensuring continuous operation by managing disruptions during roasting phases, like sudden power cuts, with its robust, computerized control system. This innovative equipment supports automated weighing processes, triggering alarms for immediate attention to irregularities, thus preserving batch quality. Ideal for diverse coffee applications, it efficiently integrates into existing processing lines, handling multiple shifts with ease. Constructed for durability and efficiency, the system is compatible with integration into upstream roasting machines, providing seamless sampling and testing solutions, and is designed to cater to the demanding environments of coffee processing plants.

Benefits

- Ensures continuous operation by effectively managing interruptions in roasting cycles.

- Preserves coffee quality through automated sampling and alarm-triggered interventions.

- Increases operational efficiency with computerized controls tailored for espresso roasting.

- Seamless integration into existing processing lines minimizes setup time.

- Enhances product consistency and quality with precise weighing and testing capabilities.

- Applications

- Espresso coffee, Coffee roasting systems, Roasted coffee

- End products

- Dark roast coffee, Medium roast coffee, Ground espresso coffee, Espresso beans, Espresso blend

- Steps before

- Coffee Bean Selection, Pre-roasting

- Steps after

- Weighing, Quality Control Testing

- Input ingredients

- green coffee beans

- Output ingredients

- roasted coffee, ground coffee, samples for quality control

- Market info

- Scolari Engineering is known for designing and manufacturing custom-engineered drying systems and equipment, particularly for the food and agricultural industries, leveraging innovative technology and a strong reputation for quality and reliability.

- Software

- Microsoft® Windows 7/10, Microsoft® C, Microsoft® C Sharp

- Roasting phase control

- Computerized, espresso specific

- Alarm system

- Yield monitoring and irregular drop alert

- Operating shifts

- Three shifts

- Construction type

- Modular "skid" construction

- Automation level

- PLC

- Batch vs. continuous operation

- Batch

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Touchscreen

- Modular construction

- Yes

- Control Software

- Microsoft® Windows 7/10

- Control Panel Language

- Microsoft® C, C Sharp

- Modular Construction

- Modular "skid" for rapid assembly

- Operating Shift Compatibility

- Three shifts

- Software Updates

- New releases for continual customer requirements

- Pneumatic Sampling System

- For sample transfer to QC