Soft pod packaging solution for coffee

Streamline your coffee production with a compact, high-speed solution that ensures precise pod counting, compostable packaging, and integrated grinding, all while maintaining aroma and freshness.

Produces and Packages Soft Coffee Pods

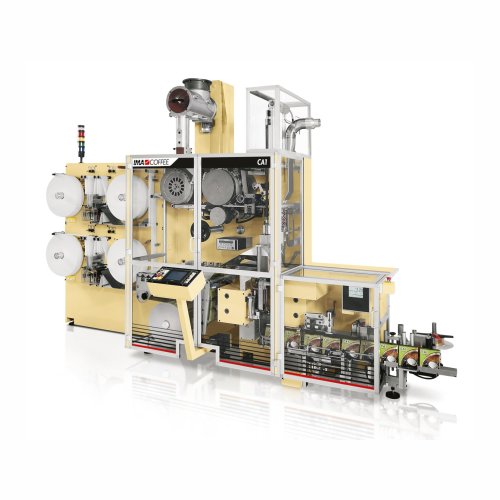

The CA 1 from IMA Group is a versatile soft pod coffee packaging machine that excels in integrating multiple processes within a space-efficient design. Capable of producing up to 800 soft coffee pods per minute, the CA 1 effectively combines pod counting, stacking, and pack forming in one streamlined operation. Its innovative gas flushing unit minimizes coffee oxidation, ensuring long-lasting flavor with low oxygen residue, while the automatic filter paper splicing system enhances efficiency. Compatible with compostable and recyclable materials, the CA 1 supports sustainable packaging solutions. Engineered for continuous, high-speed operations, the machine features a programmable electronic counting system for accurate pod stacking and a lubrication-free design for cleaner processing. Optional customization includes an integrated coffee grinder, enhancing the machine’s functionality without increasing its footprint. The CA 1 stands out for its flexibility, user-friendly operation, and ability to adapt to various pod configurations, making it ideal for coffee producers and packaging companies seeking efficient and environmentally friendly packaging solutions.

Benefits

- Optimizes production efficiency with high-speed output of up to 800 pods per minute.

- Minimizes coffee oxidation, preserving flavor with low oxygen residue (<1%).

- Enhances sustainability through compatibility with compostable and recyclable packaging materials.

- Requires minimal maintenance with a lubrication-free design for cleaner operations.

- Offers versatile packaging options with customizable pod configurations and integrated grinding capabilities.

- Applications

- Coffee packaging, Single-dose coffee, Compostable coffee packaging, Recyclable coffee packaging, Soft pod coffee

- End products

- Stand-up coffee pod bags, Compostable coffee pods, Soft coffee pods, Recyclable coffee pods, Single-serve coffee pods

- Steps before

- Grinding

- Steps after

- Packing

- Input ingredients

- coffee beans, filter paper, envelope, compostable materials, recyclable materials, compressed air

- Output ingredients

- soft coffee pods, heat-sealed stand-up bags, packaged coffee pods

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Machine speed

- Up to 800 coffee pods/minute

- Capacity

- Up to 14 grams of coffee per pod

- Heat-sealed pack capacity

- Min. 8 – Max. 18 pods per pack

- Total installed power

- 23 kW

- Power consumption

- 18 kW

- Duty pressure for compressed air

- 6 bar

- Compressed air consumption

- 200 Nl/min

- Machine net weight

- Max. 4, 500 Kg

- Gas flushing unit

- Low oxygen residue (<1%)

- Automation

- Programmable electronic counting system

- Splicing system

- Automatic filter paper splicing

- Footprint

- 4.3 metre length layout

- Machine speed

- Up to 800 pods/minute

- Changeover time

- Quick changeover procedures

- Automation level

- User-friendly operation

- Batch vs. continuous operation

- Continuous

- Material handling

- Compostable and recyclable materials

- Gas flushing unit

- Low oxygen residue (<1%)

- Lubrication

- Lubrication-free machine

- Versatility

- Maximum packaging versatility

- Compostable materials

- Yes

- Recyclable materials

- Yes

- Filter paper

- Yes

- Envelope compatibility

- Yes

- Machine footprint

- 4.3 metres length

- Compact footprint

- Space-efficient 4.3 metre length layout

- Control panel type

- Touchscreen / Digital interface

- Integration possibilities

- Integrated coffee grinder

- Footprint adjustment

- Compact, 4.3 metre layout

- Machine lubrication

- Lubrication-free

- Gas flushing

- Optional gas flushing unit

- Filter paper splicing

- Automatic splicing system

- Pack versatility

- Numerous optional groups for customization