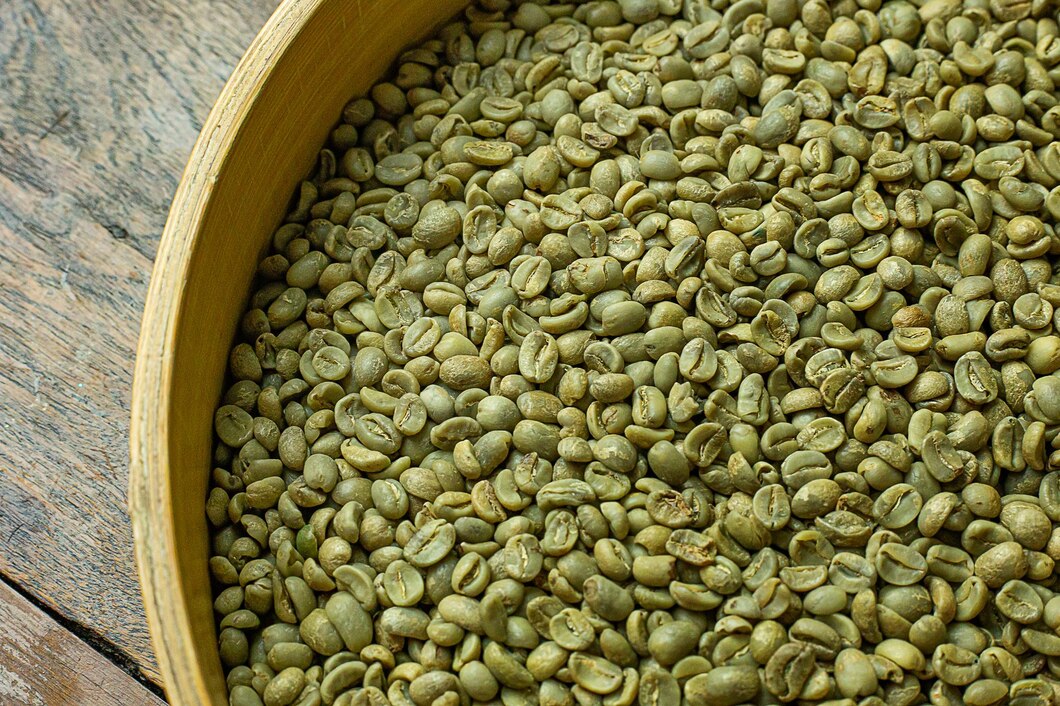

Compression pneumatic line for green coffee handling

Streamline your coffee production with a compression pneumatic line that efficiently handles green coffee unloading, cutting, and batching, ensuring seamless integration into your processing operations while maintaining product integrity.

Handles, Cuts, and Batches Coffee Beans

Scolari Engineering’s Compression Pneumatic Line is a semi-automatic solution engineered to enhance coffee processing efficiency by automating key stages such as unloading, cutting, and batching. This system is ideal for coffee manufacturers and roasters focused on producing green coffee beans, roasted coffee beans, and ground coffee powder.

The line integrates a robust weighing-batching machine, ensuring precise measurement before the green coffee is transferred to designated silos. Its advanced compression technology optimizes the transfer of coffee beans, reducing manual input and minimizing human error. Additionally, the integrated cleaning machines and dust collecting systems maintain high-quality standards by eliminating impurities from the supply chain.

The system is capable of semi-automatic operation, supporting batch processing with complete traceability of each coffee batch, making it a versatile choice for food processing and beverage industries. Materials used in construction are selected for durability and easy maintenance, reducing downtime and operational costs. Scolari Engineering offers customization and engineering support to meet specific customer requirements, ensuring seamless integration into existing production lines.

Benefits

- Enhances production efficiency by automating unloading, cutting, and batching processes.

- Ensures product consistency with precise batch weighing and traceability.

- Minimizes manual handling errors, improving operator safety and reducing labor costs.

- Maintains coffee quality with integrated dust collection and cleaning systems.

- Customizable to integrate smoothly with existing production lines for tailored solutions.

- Applications

- Green coffee, Ground coffee, Roasted coffee

- End products

- Roasted coffee beans, Green coffee beans, Ground coffee powder

- Steps before

- Green coffee reception, Loading hopper, Cleaning, Weighing-batching

- Steps after

- Roasting, Blending, Batch distribution

- Input ingredients

- green coffee bags, loose green coffee, bagged green coffee on pallets

- Output ingredients

- weighed green coffee, cleaned green coffee, batched green coffee, sorted green coffee by size and density

- Market info

- Scolari Engineering is known for designing and manufacturing custom-engineered drying systems and equipment, particularly for the food and agricultural industries, leveraging innovative technology and a strong reputation for quality and reliability.

- Bag type

- Loose bags / Bags on pallets

- Automation

- Operator informed system, electronically controlled

- Batch size

- Variable based on roaster and blend requirements

- Cleaning machine

- Included

- Dust collecting system

- Included

- Batch documentation

- Electronic panel entry

- Weighing-batching machine

- Included

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch

- Error reduction capability

- Automated error management systems

- Traceability

- Batch traceability system

- Pneumatic system integration

- Compression pneumatic line

- Abrasion resistance

- Unspecified

- Corrosive resistance (e.g. acids)

- Unspecified

- Biological compatibility

- Unspecified

- Cleanability

- Unspecified

- Density/particle size

- Varies (e.g., 0.5–2.5 g/cm³)

- Weather resistance

- Unspecified

- Container type

- Pallets / Cisterns / Containers

- Bag type

- Loose bags / Pallets with 25 pcs

- Bag or loose pallets

- Yes

- Control panel type

- Electronic panel

- Discharge method

- Mechanical hand / Telescopic conveyor belt

- Control panel type

- Electronic panel

- Automation level

- Manual / Automatic

- Integration with existing systems

- Yes