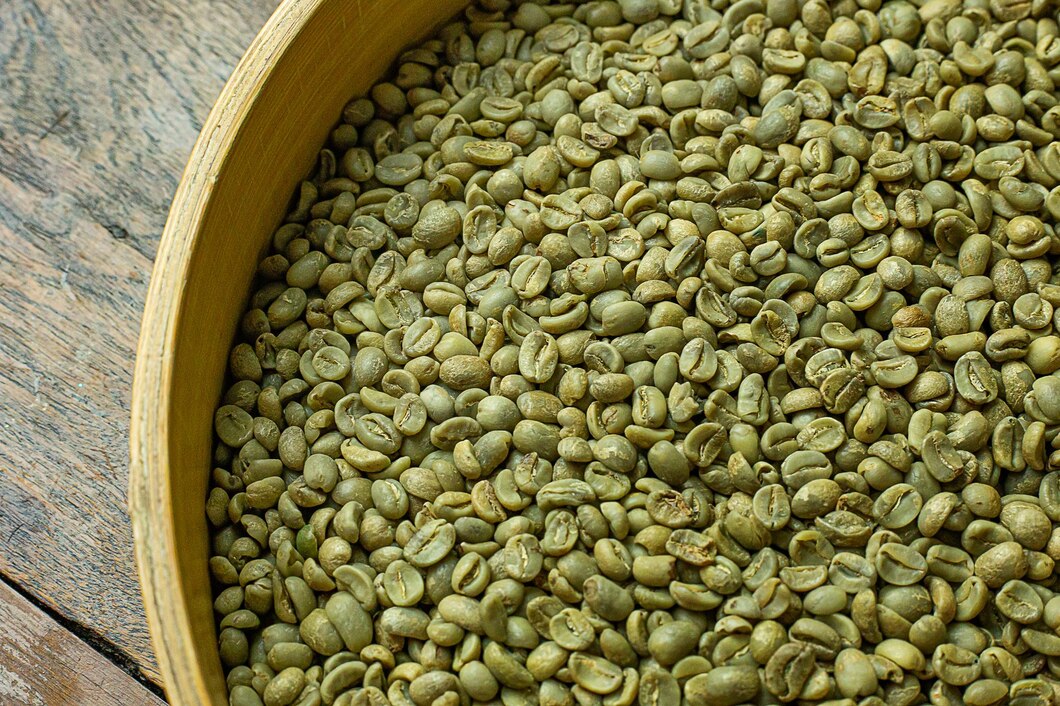

Green coffee cleaning and sorting systems

Optimize your coffee processing by integrating advanced cleaning and sorting systems designed to handle impurities, enhance raw coffee quality, and streamline production efficiency from the moment beans arrive until they’re ready for roast.

Cleans and Sorts Green Coffee Beans

The Green Coffee Cleaning and Sorting System from IMA Coffee Petroncini efficiently addresses the challenge of impurities in coffee production. This system utilizes a combination of basic cleaning sieves, densimetric tables, and dry destoners for thorough separation of foreign materials such as stones, metals, and dust. With a capacity of up to 20 tons per hour, it suits high-capacity coffee processing facilities. Integrating optical sorting technology, it enables precise sorting by shape and color, optimizing the quality of specialty green coffee blends and commercial batches. The system’s dust extraction ensures a clean working environment, while its customizable configuration allows adaptation to specific production schedules. Designed for continuous operation, it minimizes energy consumption and enhances operational efficiency.

Benefits

- Enhances coffee quality by efficiently removing impurities and defects.

- Increases operational efficiency with a high throughput of up to 20 tons per hour.

- Customizable configuration supports diverse production needs and schedules.

- Reduces energy usage with optimized system integration and operation.

- Maintains a clean work environment through effective dust extraction.

- Applications

- Coffee processing, Green coffee beans, Coffee cleaning, Coffee sorting, Coffee packaging, Coffee production

- End products

- Commercial coffee batches, Unroasted coffee beans, High-grade sorted coffee beans, Cleaned raw coffee beans, Bulk coffee bean packages, Specialty green coffee blends

- Steps before

- Raw Coffee Bean Receipt, Initial Inspection

- Steps after

- Roasting, Grinding, Primary Packaging, Secondary Packaging, End of Line Processing

- Input ingredients

- green coffee beans, foreign bodies, impurities, stones, iron-based impurities, wood, aluminium impurities, pieces of metal

- Output ingredients

- clean coffee beans, sorted coffee beans, dust-free coffee, commercial value enhanced coffee, refilled big bags, coffee in storage silos

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Capacity

- Up to 20 ton/h

- Cleaning method

- Dry destoning, optical sorting, basic sieving

- Impurity removal

- Iron, stones, wood, aluminium, metal

- Automation

- Customised plant configuration

- Sorting accuracy

- By shape and colour

- Dust extraction system

- Integrated dust-tight aspiration

- Working mechanism

- Optical sorting, densimetric table, dry destoner

- Integrated steps

- Cleaning, sorting, dust extraction

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Cleaning method

- Dry

- Changeover time

- Optimized for efficiency

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Frequency of defect types

- Adjustable

- Machine footprint

- Customised plant configuration

- Sieve size

- Basic cleaning sieve with magnetic surface

- Gravity table size

- Densimetric/gravity table

- Dust extraction system

- Integrated superior dust extraction

- Optical sorting capability

- Optical sorting machines for every processing capacity

- Destoner size

- Dry destoner for removing foreign bodies

- Customised plant configuration

- Includes/excludes cleaning passes as needed

- Plant configuration

- Customised to production rate and facility layout

- Cleaning passes

- Configurable to include/exclude based on schedule

- Optical sorting parameters

- Adjustable for defect separation

- Magnetic surface option

- For iron-based impurity removal

- Dust extraction

- Integrated system with airflow control