Tangential coffee roaster for diverse roasting profiles

Achieve unparalleled precision and flexibility in coffee roasting with this solution, ensuring consistent color and moisture content across all roast profiles, from espresso to single-origin gourmet blends.

Processes and Roasts Coffee Beans Efficiently

The JUPITER Tangential Roaster from PROBAT SE revolutionizes coffee processing by allowing complete control over the roasting process to meet diverse market demands. This roaster utilizes a closed and stationary roasting chamber with specially developed rotating shovels that mix and move coffee beans, ensuring uniform heat distribution through convection. Suitable for coffee producers, roasting companies, and specialty coffee roasters, it efficiently processes and roasts a range of coffee types—such as espresso, Italian, and single-origin gourmet blends. The system offers flexible roasting times from 1.5 to 18 minutes and accommodates batch sizes up to 780 kg, depending on the model, with a throughput reaching up to 5,000 kg/h in continuous operations.

Equipped with the PILOT 2020 ROASTER control system, it allows for precise modification of roasting parameters and supports recipe management with flexible definable settings. Energy-efficient features include minimal heat loss and enhanced energy savings through exhaust air recirculation and green-coffee preheating. The machine comes in versions powered by natural gas, propane, or hydrogen, with an option for a retrofitting kit to accommodate alternative energy sources. With advanced safety features, such as online CO monitoring and thermal cleaning, the JUPITER ensures not only optimal performance but also high operational safety and ease of maintenance. Additionally, various customization options and engineering support are available, making it an adaptable solution for managing diverse coffee roasting demands.

Benefits

- Enables consistent roasting across diverse coffee profiles, enhancing product quality and variety.

- Minimizes energy use through efficient heat management and exhaust air recirculation.

- Streamlines operations with fast recipe changes and rapid cooling, increasing production speed.

- Adaptable to alternative fuels, ensuring future-proof and sustainable operations.

- Simplifies maintenance with modular design and advanced safety features.

- Applications

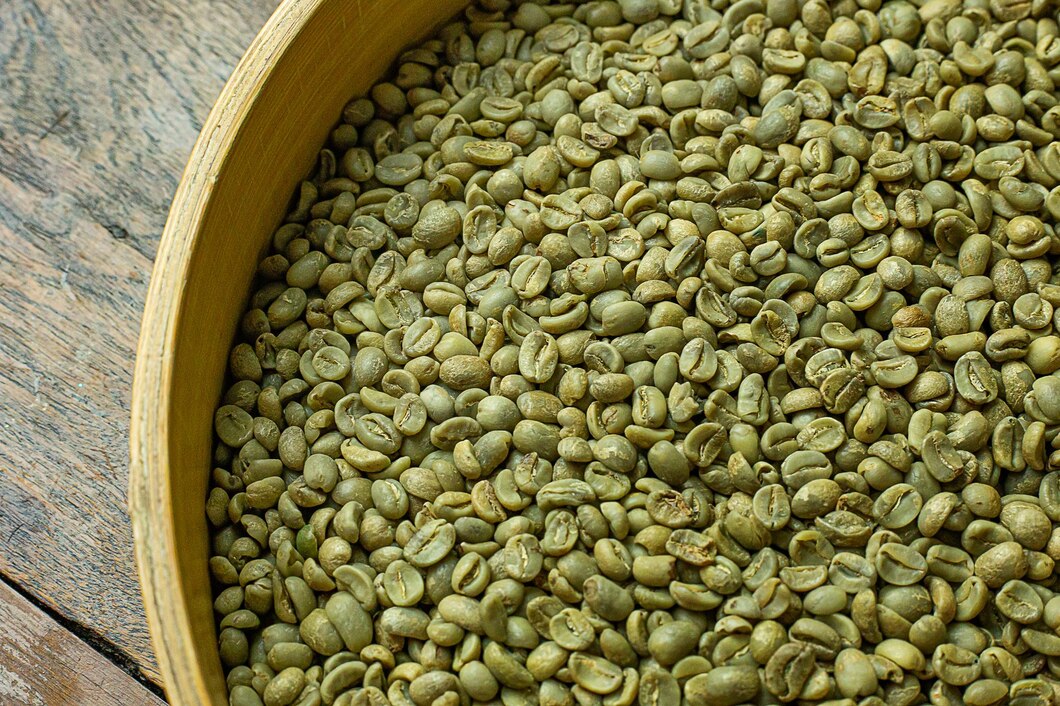

- Specialty coffee, Green coffee, Coffee blends, Coffee beans

- End products

- Light roast coffee, Dark roast coffee, Medium roast coffee, Espresso roast coffee, Flavored coffee beans, Cold brew coffee, Italian roast coffee, French roast coffee, Single-origin gourmet coffee, Arabica coffee specialty blends

- Steps before

- Green coffee procurement, Green coffee grading, Green coffee cleaning, Green coffee blending

- Steps after

- Cooling, Packaging, Grinding, Quality control

- Input ingredients

- green coffee beans, non-uniform coffee beans, small coffee beans

- Output ingredients

- roasted coffee, whole beans, crushed coffee, light roast, dark roast, uniform bean appearance, homogeneous roast

- Market info

- Probat is renowned for its expertise in manufacturing coffee processing equipment, particularly coffee roasters. The company has a strong reputation for engineering solutions in industrial coffee roasting, blending, and grinding technology.

- Roasting time

- 1.5–18 min

- Roasting capacity

- Up to 5, 000 kg/h

- Batch size

- 47–780 kg

- Heating

- Natural gas, propane, hydrogen

- Energy loss

- Minimized by insulation

- Cooling time

- Extremely rapid and uniform

- Automation

- PILOT 2020 ROASTER control system

- Temperature control

- Controlled roasting air and mechanical mixing

- Flavor adjustment

- Flexible adjustment of key parameters

- Energy savings

- Recirculation and preheating of green coffee

- Exhaust air treatment

- Proforte system

- Web-based control

- Allows access from different devices

- Automation level

- Fully automatic with PILOT 2020 ROASTER control system

- Batch vs. continuous operation

- Batch

- Changeover time

- Rapid recipe changes

- CIP/SIP

- Systematic water addition for process control

- Cleaning method

- Minimal maintenance due to modular design

- Energy efficiency

- Minimized energy loss through insulation

- Heat application method

- Convection with controlled airflow

- Recipe management

- Flexibly definable, automatic

- Roasting time versatility

- 1.5 - 18 minutes

- Roasting temperature control

- Precise timing and temperature curves

- Safety systems

- Multistep safety system, online CO monitoring

- Cooling method

- Extremely rapid and uniform cooling

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Yes

- Heating method

- Natural gas, propane, hydrogen

- Design type

- Tangential roaster

- Cooling method

- Pre-cooling with water

- Modular design

- Easy-to-access

- Control System

- PILOT 2020 ROASTER

- HMI Type

- Touch-optimized

- Recipe Management

- Flexibly definable recipes

- Heating Options

- Natural gas, propane, hydrogen

- Modular Design

- Easy-to-access

- Roasting Time

- 1.5-18 minutes

- Batch Size

- 47-780 kg

- Recirculation and Exhaust Air Treatment

- Optional

- Hydrogen-Powered Version

- Available

- Retrofit Kit

- Available on request