Specialty coffee roaster for small batch production

Enhance your coffee roasting precision with advanced heat control and profile customization, allowing you to achieve distinct sensory profiles and ultimate aroma development for your specialty blends.

Roasts and Cools Coffee with Customizable Profiles

The Petroncini TT Series Specialty Coffee Drum Roasters are designed for small-scale industrial roasters and artisan coffee producers, offering unparalleled control over roasting profiles. Utilizing a drum roasting system, these machines accommodate batch and manual operations, perfect for specialty beans and blends. With models like the TT 5/10, TT 15/20, and TTG 60, processing capacities range from 35 kg/h to 280 kg/h. Advanced features include heat control, air management, and profile customization, allowing precision from light to dark roasts. Equipped with a modulating burner and independent fans for roasting and cooling, these roasters ensure uniform heat distribution and optimal energy use. Integration is seamless with optional remote monitoring and MAESTRO software for enhanced operational control. Crafted with durable materials, they are engineered for long-lasting performance in the demanding environments of the coffee and food and beverage industries.

Benefits

- Maximizes flavor development with precise roast profile control.

- Enhances energy efficiency with adjustable heat and air management.

- Supports diverse coffee products, from espresso to artisan blends.

- Minimizes downtime through quick setup and independent cooling.

- Ensures consistent quality with customizable and repeatable roasting cycles.

- Applications

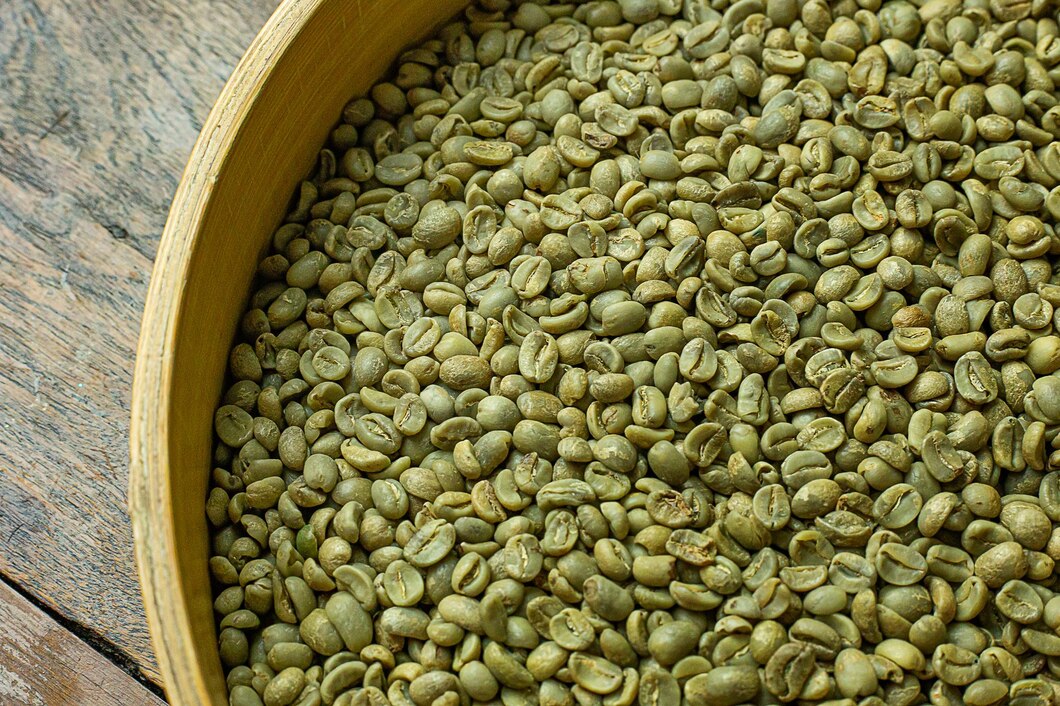

- Specialty coffee, Roasted coffee beans, Green coffee beans

- End products

- Espresso coffee, Dark roast coffee beans, Specialty artisan coffee blends, Light roast coffee beans, Whole bean coffee

- Steps before

- Green Coffee Systems, Coffee Sorting, Cleaning, De-stoning

- Steps after

- Cooling, Grinding, Roasted Coffee Storage, Packaging

- Input ingredients

- green coffee beans

- Output ingredients

- roasted coffee beans

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Roasting Time

- 10–20 min

- Capacity

- Up to 35 kg/h, Up to 70 kg/h

- Batch Size

- 3/10 kg, 10/20 kg

- Power

- Single phase

- Burner Modulation

- 0 – 100%

- Setpoints

- 8 setpoints

- Roasting Profiles

- 20 customization options

- Rate-of-Rise Monitoring

- Yes

- Crack Temperatures Saving

- Yes

- Remote Assistance

- Available

- Cooling Fans

- Independent

- Roasting control

- Adjustable air volume, heat, and drum speed

- Roasting type

- Soft roasting profile

- Heat transfer method

- Convection and conduction

- Roasting profiles customization

- 8 setpoints and 20 profiles

- Remote assistance

- Available

- Automation level

- MAESTRO software with Classic/Avantgarde versions

- Changeover time

- Rapid between roasting profiles

- Batch vs. continuous operation

- Batch

- Cooling method

- Independent fans for roasting and cooling

- Sensor monitoring

- Rate-of-Rise and Crack temperatures

- Footprint (Length x Width x Height)

- TT 5/10

- Footprint (Length x Width x Height)

- TT 15/20

- Footprint (Length x Width x Height)

- TTG 60

- Batch Size

- TT 5/10

- Batch Size

- TT 15/20

- Batch Size

- TTG 60

- Capacity

- TT 5/10

- Capacity

- TT 15/20

- Capacity

- TTG 60

- Control panel type

- Classic / Avantgarde