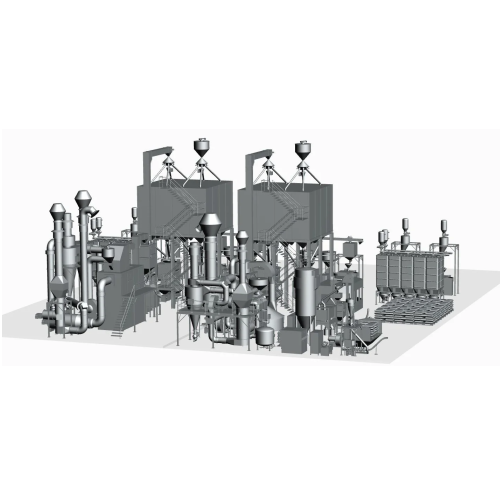

Custom coffee roasting plant solutions

Optimize your coffee production line with scalable plant solutions that integrate seamlessly from roasting to packaging, ensuring precision, efficiency, and quality in every batch.

Roasts, Grinds, and Packages Coffee Beans Efficiently

PROBAT’s Modular Coffee Processing Plant Solution is crafted for those aiming to enhance their coffee processing capabilities with precision. This tailored system supports a seamless integration of roasting, grinding, and packaging processes within your production line. Its modular design accommodates continuous, automated operation, optimizing energy use and supporting scalable throughput, whether handling solid, granules, or powder forms of coffee. Capable of processing from modest hourly outputs to several tons, it incorporates high-efficiency drum, tangential, and centrifugal roasters, as well as roll grinders, ensuring versatile application across various coffee end-products—from roasted beans to coffee pods. The system’s PLC control offers comprehensive production data acquisition, fostering maximum operational transparency and reliability. With customizable options, including advanced environmental technologies for energy recovery and emission minimization, it also aligns with location-specific regulations, ensuring compliance and efficient operation. The solution’s engineered-to-order design is backed by robust engineering support, accommodating specific material needs and enhancing maintenance with features like CIP for effortless cleaning.

Benefits

- Increases production efficiency through continuous, automated operation.

- Reduces energy costs by utilizing advanced heat recovery systems.

- Enhances product quality with precise roasting and grinding control.

- Complies with environmental standards, minimizing emissions and waste.

- Offers scalable solutions to fit diverse production capacities and requirements.

- Applications

- Coffee processing, Coffee plant solutions, Coffee roasting, Coffee packaging, Coffee grinding

- End products

- Coffee powder, Coffee pods, Coffee capsules, Coffee bags, Roasted coffee beans, Ground coffee

- Steps before

- Receiving green coffee, Feeding into machine, Preheating, Grinding

- Steps after

- Packing, Controlled gassing, Degassing, Emission protection, Heat recovery

- Input ingredients

- green coffee

- Output ingredients

- roasted coffee, ground coffee, packaged coffee

- Market info

- Probat is renowned for its expertise in manufacturing coffee processing equipment, particularly coffee roasters. The company has a strong reputation for engineering solutions in industrial coffee roasting, blending, and grinding technology.

- Capacity

- 250 kg/hr to several tonnes/hr

- Automation

- PLC-controlled

- Environmental Technology

- Flameless, regenerative thermal oxidation (PROFORTE)

- Emission Values

- Lowest emission values

- Thermal Efficiency

- Extremely high

- Energy Savings

- Green coffee preheating, modular exhaust air treatment

- Heat Recovery

- Heat exchangers usage

- Operating Concepts

- Production Data Acquisition (PDA), Production Management

- Cooling Method

- Special conveyor system with compressor

- Output Range

- 250 kg to more than 5 tons/hr

- Control System

- Integrated plant control systems

- Safety System

- Multistep safety system

- Degassing Control

- Controlled gassing and degassing

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Changeover time

- Quick changeover capabilities

- System integration

- End-to-end process integration

- Cleaning method

- CIP / Manual

- Environmental impact

- Low emissions / Sustainability

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customizable size depending on capacity

- Tank shape

- Drum

- Feed method

- Automated feed system

- Discharge method

- Automated discharge system

- Control panel type

- PLC-based control

- Compact footprint

- Modular design for optimized space usage

- Control System

- PLC / SCADA Integration

- Control Solution

- Custom PLC Solutions

- Roaster Design

- Modular

- Plant Size

- Small / Medium / Large

- Emission Control

- Thermal Pre-cleaning / Catalytic Afterburner

- Energy Recovery System

- Heat Exchangers

- Safety Features

- Safety PLCs / Emergency Concepts

- Production Management

- PDA / Production Data Acquisition

- Capacity Output

- 250 kg/h to 5+ tons/h

- Process Optimization

- Lean / Flexible Solutions