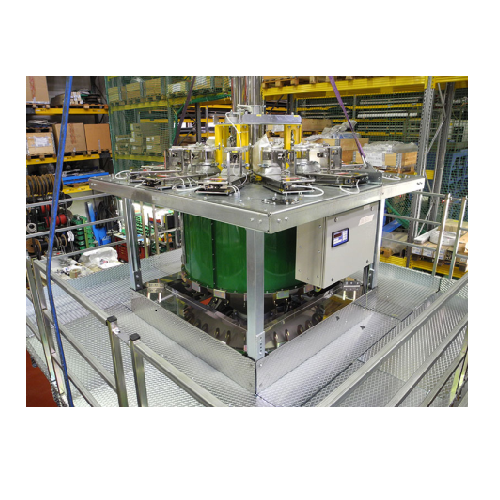

Green coffee unloading and batching system

Streamline your coffee processing with a system that efficiently unloads, cleans, and batches green coffee, ensuring precise blend preparation and seamless integration into your roasting process.

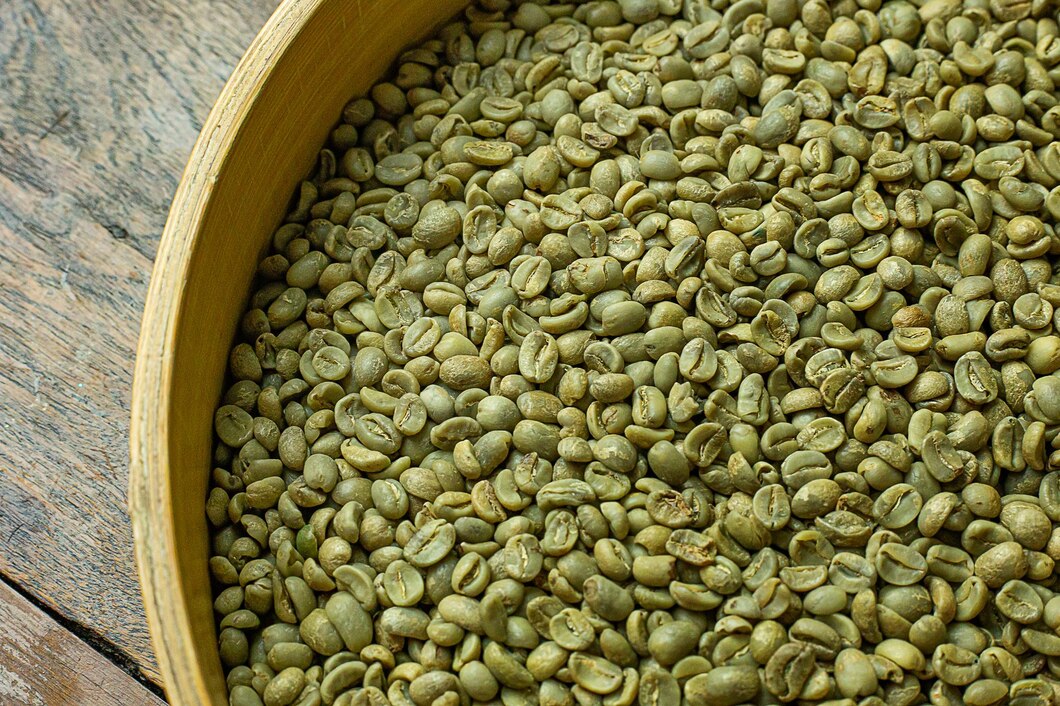

Unloads, Cleans, and Batches Green Coffee Beans

The Green Coffee Unloading and Batching System from Scolari Engineering provides seamless integration into coffee processing lines by efficiently handling the unloading, cutting, and batching of green coffee beans. This system stands out with its capability to minimize operator errors through automated batch management and traceability. It supports a wide range of operations including manual and automatic modes, making it adaptable to both small-scale and industrial coffee manufacturers. With a capacity to process various forms of green coffee, from loose beans in containers to bagged products on pallets, it’s designed for flexibility and precision. The system’s components, such as the coffee cleaning and weighing-batching machines, ensure thorough cleaning and accurate batching, optimizing the entire preprocessing stage. Scolari Engineering’s commitment to reducing operational errors has enabled this system to operate reliably in high-speed environments for over a decade, demonstrating both durability and efficiency.

Benefits

- Increases operational efficiency by automating unloading and batching processes.

- Reduces labor errors through automated batch traceability and management.

- Enhances coffee quality consistency with precise cleaning and batching.

- Adapts to various coffee forms, improving flexibility in processing.

- Streamlines integration into existing lines with versatile processing capabilities.

- Applications

- Green coffee, Coffee beans, Roasted coffee

- End products

- Green coffee blends, Roasted coffee blends, Unroasted coffee pallets, Bulk green coffee for roasting, Unroasted coffee batches, Whole green coffee beans

- Steps before

- Receiving, Sorting, Unloading, Cutting, Emptying

- Steps after

- Roasting, Blending, Packaging, Roasted Coffee Production

- Input ingredients

- green coffee bags, loose green coffee, pallets of green coffee, green coffee beans

- Output ingredients

- weighed green coffee, cleaned green coffee, batched green coffee, prepared green coffee blends

- Market info

- Scolari Engineering is known for designing and manufacturing custom-engineered drying systems and equipment, particularly for the food and agricultural industries, leveraging innovative technology and a strong reputation for quality and reliability.

- Automation

- PLC-controlled

- Bag type

- Loose / Palletized / Container

- Batch size

- Variable, based on blends and selection

- Batch vs. continuous

- Batch

- Dosing type

- Automatic / Manual

- Dust collection system

- Integrated

- Energy Usage per Batch

- Not specified

- Feed rate

- Depends on coffee type and destination

- Product compatibility

- Green coffee

- Storage type

- Round and square silos

- Weight measurement accuracy

- Net weight

- Roasting control

- Automatic via roasting curve

- Cleaning method

- Integrated cleaning machine

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual / Automated

- Error reduction

- Optimized for operator error reduction

- System protection

- Prevents mixing of different coffee types

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Bag or loose pallets

- 25 pcs per pallet

- Control panel type

- Electronic panel

- Integration possibilities

- Batch management and traceability system

- Bag cutting method

- Manual / Automatic

- Unloading method

- Mechanical hand / Telescopic conveyor belt

- Roasting curve automation

- Automatic by blend code