Roasted coffee batch weighing and management system

Optimize your coffee production with our advanced system, designed to streamline unloading, cleaning, weighing, and roasting processes to ensure consistent quality and precise traceability for your diverse coffee blends.

Weighs and Batches Roasted Coffee

The Roasted Coffee Scale from Scolari Engineering is designed to precisely weigh and batch roasted coffee, streamlining operations for coffee roasters and producers. Utilizing a robust weighing system, it ensures accurate measurements and traceability across a variety of coffee types, from espresso beans to specialty blends. Offering seamless integration into existing roasting lines, this system accommodates batch and continuous operations. Configurable with PLC controls, it enhances process automation and minimizes human error. Built with durable materials, it withstands rigorous production environments, ensuring longevity and reliability. The system’s design optimizes energy use, reducing operational costs while maintaining high performance.

Benefits

- Enhances production accuracy and consistency with precise weighing and batching.

- Streamlines operations, reducing human error through automated processes.

- Supports diverse coffee types and roasting levels, increasing production flexibility.

- Integrates seamlessly into existing production lines for efficient scaling.

- Optimizes energy use, lowering operational costs and improving sustainability.

- Applications

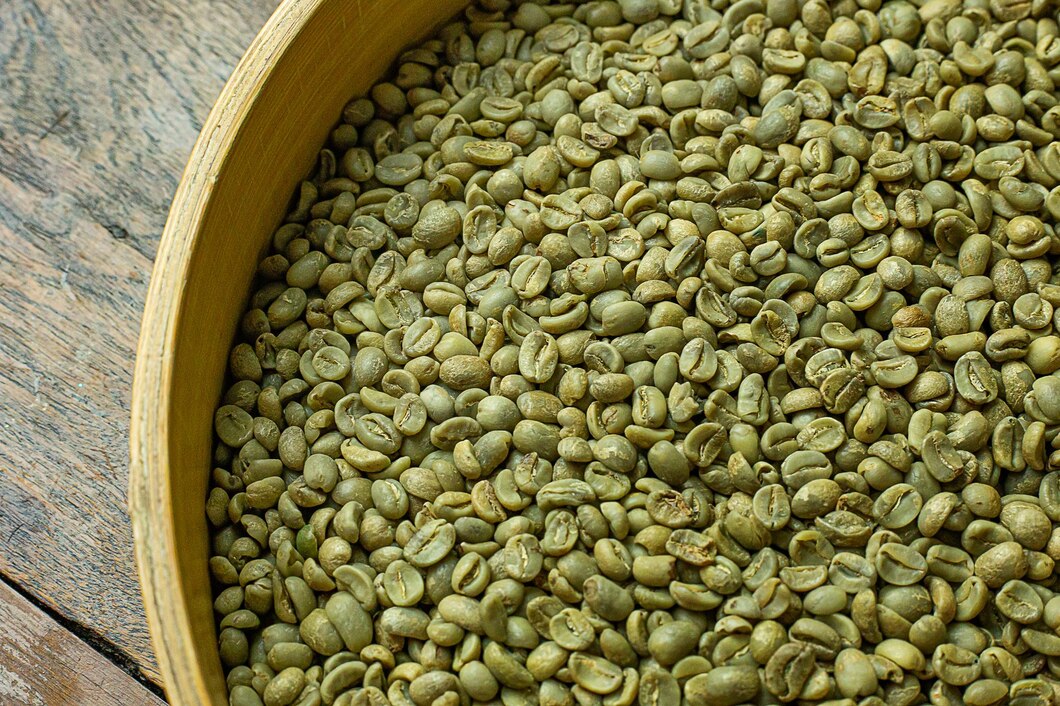

- Green coffee, Ground coffee, Roasted coffee

- End products

- Cold brew coffee grounds, Light roast coffee, Arabica coffee beans, Espresso coffee beans, Decaf roasted coffee, Single-origin roasted coffee, Specialty coffee blend, Espresso ground coffee, Italian roasted coffee, French roast coffee

- Steps before

- Green Coffee Reception, Cleaning, Weighing, Batching, Blending

- Steps after

- Roasting, Packaging

- Input ingredients

- green coffee, bags, green coffee bags, loose grain, green coffee silos

- Output ingredients

- roasted coffee, roasted coffee batch

- Market info

- Scolari Engineering is known for designing and manufacturing custom-engineered drying systems and equipment, particularly for the food and agricultural industries, leveraging innovative technology and a strong reputation for quality and reliability.

- Green Coffee Reception Types

- Loose, Bag on Pallets, Loose Bags

- Conveyor System

- Telescopic conveyor belt

- Automation

- PLC-controlled

- Roasting Curve Automation

- Automated by blend code

- Blending Menu

- Pre-programmed, Easy to Modify

- Batch Management

- Traceability Enabled

- Roaster Capacity

- Varies by Product Selection

- Cleaning Machine

- Integrated

- Weighing-batching Machine

- Included

- Dust Collecting System

- Implemented

- Cyclone System

- Decantation Cyclone

- Silo Type

- Round and Square Silos

- Product Delivery Unit

- Rotating Distributor Unit

- Automation level

- PLC/Computer-controlled

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual/Automatic Bag Cutting

- Error reduction capability

- Integrated traceability system

- Integrated steps

- Weighing, batching, and roasting

- Roasting curve automation

- Automatic by product/blend code

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact or varied size depending on installation

- Container Type

- Cisterns, containers, bags on pallets

- Feed/Discharge Method

- Telescopic conveyor belt

- Control Panel Type

- Electronic panel

- Silo Shape

- Round and square options

- Discharge Method

- Manual or automatic bag cutting

- Control panel type

- Electronic panel

- Batching management

- Pre-programmed blends menu

- Roasting curve control

- Automatic by product or blend code

- Silo segregation control

- System protection against mixing

- System traceability

- Batches and traceability management