Automatic lab roaster for 1 kg coffee batches

Perfect for coffee roasters aiming to refine roast profiles, this lab roaster handles 1 kg batches with precision, ensuring consistent results essential for quality control and specialty blends.

Roasts and Analyzes Coffee in Controlled Batches

The Lab Roaster 1 kg Automatic from Scolari Engineering is a sophisticated roasting solution tailored for small-scale and specialty coffee operations. Engineered with a modular skid construction for ease of installation and relocation, this equipment leverages 45 years of industry expertise to deliver precise control over the roasting process, crucial for espresso and specialty coffee profiles. It features a fully computerized system utilizing Microsoft® Windows 7/10 for seamless integration into modern production lines, with customized software that addresses medium to dark roast parameters, pivotal for espresso-style beans.

The Lab Roaster handles all aspects of the roasting cycle, from the initial green coffee roasting stages to post-roast weighing. Its automated sampling system ensures that each batch’s quality is consistent and aligns with stringent quality control standards, sending samples to the QC department efficiently. Designed for continuous operation, it supports three-shift production environments, making it a versatile choice for coffee manufacturers, R&D labs, and specialty producers. The automatic alarm system provides immediate alerts for potential issues such as irregular drops in yield, minimizing batch loss and maximizing operational efficiency.

Benefits

- Enhances product consistency with precise roasting control tailored to espresso and specialty coffee profiles.

- Minimizes operational disruptions with automated alarm systems for real-time issue detection.

- Streamlines quality assurance processes through efficient, automated sample collection and analysis.

- Facilitates flexible production with a modular skid design ideal for dynamic lab settings.

- Maximizes productivity in continuous operation environments, supporting 24/7 roasting cycles.

- Applications

- Green coffee, Ground coffee, Roasters, Roasted coffee

- End products

- Espresso coffee, Dark roast coffee, Medium roast coffee, Espresso blend, Specialty coffee samples, Quality control coffee samples

- Steps before

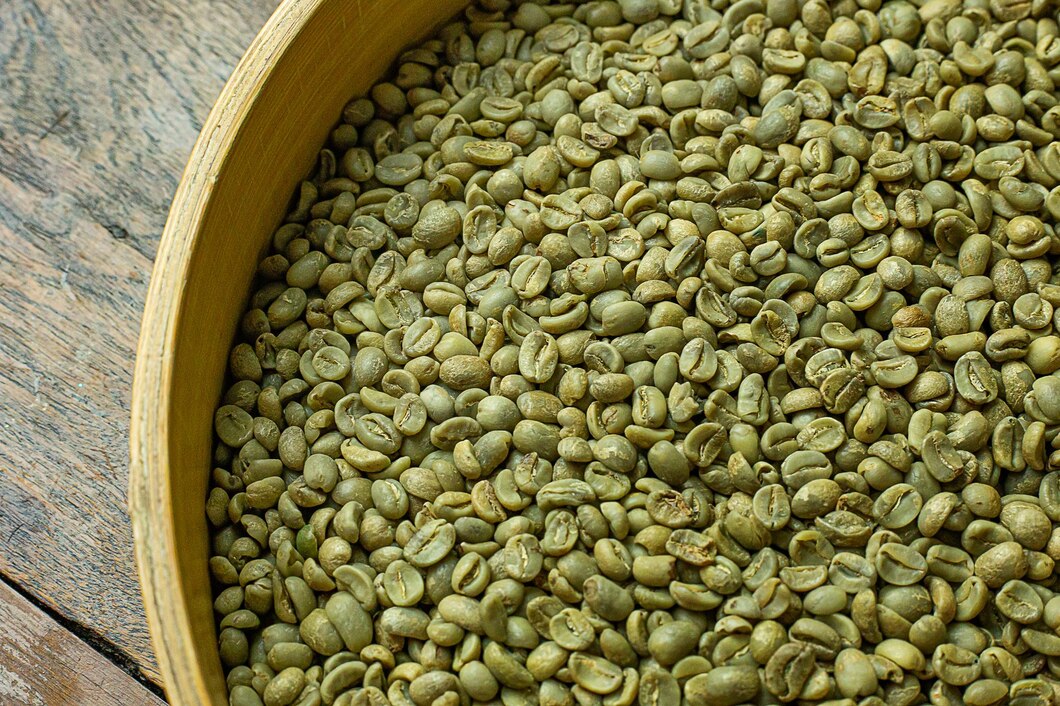

- Green Coffee Selection, Weighing

- Steps after

- Quality Control Testing, Packing

- Input ingredients

- green coffee

- Output ingredients

- roasted coffee

- Market info

- Scolari Engineering is known for designing and manufacturing custom-engineered drying systems and equipment, particularly for the food and agricultural industries, leveraging innovative technology and a strong reputation for quality and reliability.

- Roaster Capacity

- 1 kg

- Automation

- Automatic

- Control System

- Computerized

- Operating System

- Microsoft® Windows 7/10

- Programming Languages

- Microsoft® C, C Sharp

- Shift Operation

- Three shifts

- Construction

- Modular "skid" construction

- Specialization

- "Espresso" coffee roasting

- Roasting Profile

- Medium to dark roasting

- Sampling System

- Pneumatic sampling system

- Alarm System

- Automated alarm for irregular yield drops

- Automation Level

- Automatic

- Control System

- Computerized

- Roasting Control

- Medium to Dark Roast

- Power Management

- Handles Power Cuts

- Temperature Control

- Software Driven

- Batch vs. Continuous Operation

- Batch

- Sample Testing

- Pneumatic System

- Weight Checking

- Automated Alarm for Yield Loss

- Compact footprint

- 1 kg capacity

- Construction type

- Modular "skid" construction

- Machine footprint

- Laboratory size

- Control Software

- Microsoft® Windows 7/10

- Modular Construction

- Skid

- Control Languages

- Microsoft® C, C Sharp

- Pneumatic Sampling System

- Included